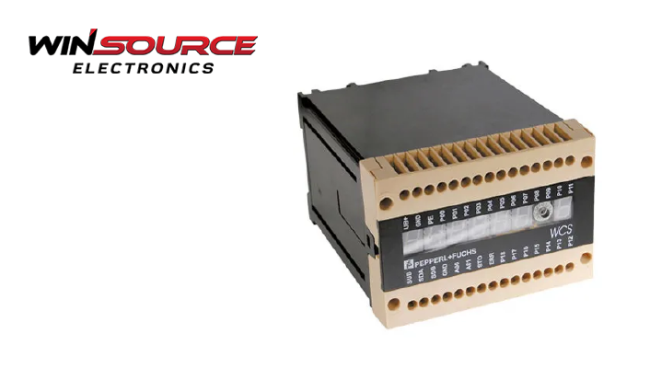

In industrial automation, precision is more than a “nice-to-have.” It’s a vital necessity. The WCS-IP111 sensor, which is flawlessly integrated into the PosiTrack System, represents the practical implementation of state-of-the-art technology within modern industrial environments. The WCS-IP111 sensor is a compact device that ensures precision and efficiency in industrial processes. There are several fundamentals to be aware of, which we’ll unpack now.

An Overview of WCS-IP111 Sensor

Key Features

The WCS-IP111 sensor operates on a single practical premise — uncompromising precision. The sensor showcases this practicality with its integrated display. This is necessary for quick monitoring and connection capabilities. Invariably, this is what allows the effective connection of up to four read heads – namely, an LS211 or LS111.

Installation Made Easy

The WCS-IP111 sensor is mounted on a DIN rail, which not only saves space but streamlines the entire installation process. Its integrated bus termination further simplifies wiring, making it an ideal fit for industrial setups where efficiency is important.

Data Output Expertise

Armed with a Gray code output, the WCS-IP111 sensor ensures accurate and reliable data transmission. Simply put, this means that you’re getting the right information at the right time. Ultimately, this is a crucial piece of the puzzle for optimizing industrial workflows.

Electrical Efficiency

Operating on 24 V DC with a power consumption of ≤ 2 W (without read heads), the WCS-IP111 sensor strikes a balance between performance and energy efficiency. This balance ensures reliability without unnecessary power consumption. This makes it ideal for aligning with the sustainability goals of modern industries.

PosiTrack System Integration

Connecting Read Heads with Precision

As mentioned, the WCS-IP111 sensor integrates with up to four read heads. This synergy allows for up-to-the-minute and precise data collection. This is the type of data relay needed to cater to the demands of industries where accuracy is non-negotiable. From aerospace to manufacturing, warehousing, logistics, and robotics, this will prove to be more than just a cog in the overall wheel.

DIN Rail Mounting for Practicality

Not only does DIN rail mounting ensure seamless installation, but it also minimizes downtime if it ever needs to be replaced.

Streamlined Wiring with Integrated Bus Termination

The WCS-IP111 sensor takes the hassle out of connections, streamlining the integration process for a more reliable and efficient industrial automation setup. This is thanks to the integrated bus termination feature.

Interface and Communication

Interface 1: Connection to Control System Made Simple

The WCS-IP111 sensor communicates effortlessly with the control system through a push-pull, parallel interface. With a maximum transfer rate of 500 updates per second and a push-pull output stage, it not only simplifies integration but also ensures real-time data flow for precise control.

Interface 2: Reading Head Connectivity with RS485

Connecting to reading heads is crucial, and the WCS-IP111 sensor handles it with finesse. Utilizing an RS485 interface with a half-duplex transmission method, it facilitates high-speed data transfer and reaches a maximum of 187.5 kBit/s. The integrated RS485 termination resistor further enhances signal integrity.

Input for Control: Tailoring to Specific Requirements

Equipped with two inputs for reading head addresses, the WCS-IP111 sensor allows for customization and adaptability, ensuring that it aligns with specific control requirements in any type of industrial setting.

Output for Error Conditions: Paving the Way for Swift Responses

In the event of an error condition, the WCS-IP111 sensor communicates this information through a PNP signal output. With a rated operational current of ≤ 15 mA, it provides a prompt response to potential issues. This is just one of the many factors that contribute to the overall reliability of the system.

Practical Applications

Precision Position Sensing with Gray Code Output

At the heart of the WCS-IP111 sensor is its ability to provide precise position sensing through Gray code output. This pinpoint accuracy is vital for applications where the exact position of objects or equipment is mission-critical. Warehouse automation that employs next-gen artificial intelligence to stack, place, or retrieve objects would do well with this system. Giants such as Amazon and Alibaba have all begun leaning towards automation of this nature with sensors such as the WCS-IP111.

Versatile Industrial Use Cases

Whether it’s conveyor systems that need to be seamlessly orchestrated or material handling processes that need to be optimized for efficiency, the WCS-IP111 sensor finds its place in these scenarios. It offers a reliable solution for accuracy in every movement.

Standards Conformity and Reliability

Meeting Emission Standards (EN 55011)

Where industrial automation is concerned, adherence to standards is paramount. The WCS-IP111 sensor complies with emission standards outlined in EN 55011. This not only ensures its compatibility with other equipment but also guarantees that its operation won’t introduce unwanted interference. Essentially, this contributes to a stable environment.

Noise Immunity (DIN EN 50082-2)

Industrial settings are often rife with electrical noise. The WCS-IP111 sensor, in line with DIN EN 50082-2, exhibits robust noise immunity. This means it can withstand and operate reliably in environments where electrical interference is a common challenge.

Ambient Adaptability: Operating in Varied Conditions

From temperature extremes to humidity variations, the WCS-IP111 sensor remains unfazed. Operating between 0 to 55 °C and capable of enduring storage temperatures from -40 to 70 °C, it ensures reliable performance in a wide range of conditions.

Overall, the WCS-IP111 sensor is a great choice for anyone wanting to streamline their industrial operations with a reliable and sustainable system.

No matter what your industry, WIN SOURCE is your trusted partner. Explore the WCS-IP111 sensor’s capabilities or our range of products and manufacturers to experience the height of robust sensors and automation systems. Discover more about the WCS-IP111 sensor and its impact on reshaping automation at WIN SOURCE.

COMMENTS