In the ever-changing world of electronic connectivity, the 2×14 connector is a crucial component, often pivoting in linking various devices and systems.

Our latest blog article here at WIN SOURCE will explore the depths of this connector, exploring its design, applications, and indispensable role in the world of technology.

But before we get started, let’s hit the mini takeaway.

The 2×14 connector, with its 28-pin configuration, serves as a powerhouse in electronic connectivity. Its robust design enables seamless data, power, and signal transmission from telecommunications to aerospace, showcasing adaptability and reliability across diverse industries in our interconnected world.

So now, let’s begin by grasping a few of the fundamentals of this power-packed device.

Understanding the Basics

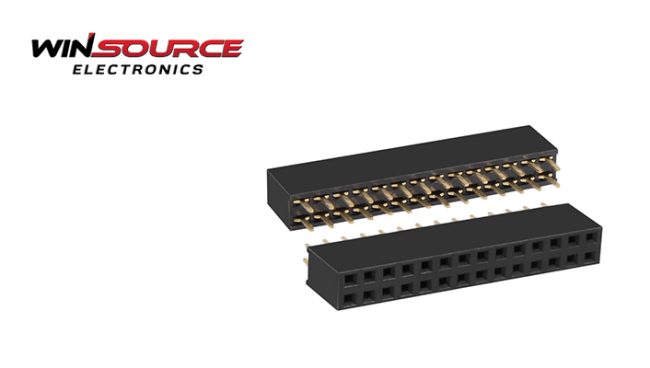

“2×14” refers to a connector with two rows of 14 pins each.

This configuration offers 28 pins, providing ample channels for transferring signals, data, or power between connected devices.

The connector is designed with precision, ensuring a secure and reliable connection.

Applications Across Industries

The versatility of the 2×14 connector makes it a staple in numerous industries.

This connector is the linchpin of seamless communication and functionality from telecommunications and data centers to automotive and aerospace applications.

Its ability to transmit signals efficiently makes it an integral part of electronic systems.

Design and Construction

Manufacturers engineer the 2×14 connector with durability and performance in mind.

High-quality materials, precision molding, and secure locking mechanisms contribute to its robust design.

The connector is often available in various configurations, such as straight or right-angle orientations, allowing installation flexibility.

Electrical Connectivity

One of the defining features of the 2×14 connector is its capacity to handle diverse electrical signals.

This connector accommodates various electrical requirements for power distribution, data transmission, or control signals.

The pin configuration ensures organized signal routing, minimizing interference and optimizing performance.

Challenges and Solutions

Despite its many benefits, challenges may arise in certain applications.

Factors like signal integrity, EMI (Electromagnetic Interference), and environmental conditions can impact performance.

Engineers and designers address these challenges by meticulously shielding, properly grounding, and using materials resistant to harsh environments.

Evolution of Connectivity

The journey of the 2×14 connector is intertwined with the evolution of connectivity in the digital age.

Conceived initially to address the need for a compact yet efficient interconnection solution, this connector has witnessed several iterations to keep pace with the demands of advancing technology.

Its evolution mirrors the rapid developments in electronic systems, contributing to the seamless integration of various devices and components.

Customization and Compatibility

Manufacturers recognize the importance of customization in modern applications.

The 2×14 connector is no exception, with customization options to meet specific requirements.

Engineers can choose different pin configurations, materials, and form factors based on the application’s unique demands.

This adaptability ensures compatibility across a spectrum of devices, fostering innovation and flexibility in design.

Advancements in Data Transfer

In an era where data transfer speeds are paramount, the 2×14 connector remains at the forefront.

With advancements in signal processing technologies, this connector facilitates high-speed data transmission, making it indispensable in applications that demand rapid information exchange.

Its role in maintaining the integrity of data streams positions it as a critical component in cutting-edge systems.

Reliability in Harsh Environments

Certain industries, such as aerospace and automotive, expose electronic components to extreme conditions.

The 2×14 connector’s resilience in harsh environments is a testament to its robust design.

Engineers leverage advanced materials and encapsulation techniques to ensure the connector can withstand temperature variations, vibrations, and other environmental challenges, contributing to the longevity and reliability of electronic systems.

Interplay with Industry Standards

Standardization is crucial for ensuring seamless interoperability across devices and systems.

The 2×14 connector often adheres to industry standards, facilitating widespread adoption and compatibility.

Its alignment with established norms ensures that engineers and designers can confidently incorporate it into their projects, knowing it meets the necessary criteria for performance and safety.

Environmental Considerations

As sustainability becomes a focal point in design and manufacturing, the 2×14 connector undergoes scrutiny for its environmental impact.

Manufacturers increasingly employ eco-friendly materials and production processes, aligning with global efforts to reduce electronic waste.

The connector’s longevity and reliability contribute to the overall sustainability of electronic systems, minimizing the need for frequent replacements.

With a vast selection, competitive prices, and reliable customer service, WIN SOURCE ensures a seamless procurement experience for all your connector requirements.

Empowering enthusiasts and industry leaders in electronic development to complete their projects with the best quality components.

The Power of the 2×14 Connector – T End On…

In the ever-growing landscape of electronic connectivity, the 2×14 connector is not just a link between devices but a symbol of adaptability, reliability, and progress.

Its journey from conception to widespread adoption mirrors our technological strides, and its continued evolution promises to shape the landscape of connectivity in the years to come.

As industries push the boundaries of innovation, the 2×14 connector stands ready to connect the devices that power our interconnected world.

© 2024 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS