What is a Heat Sink?

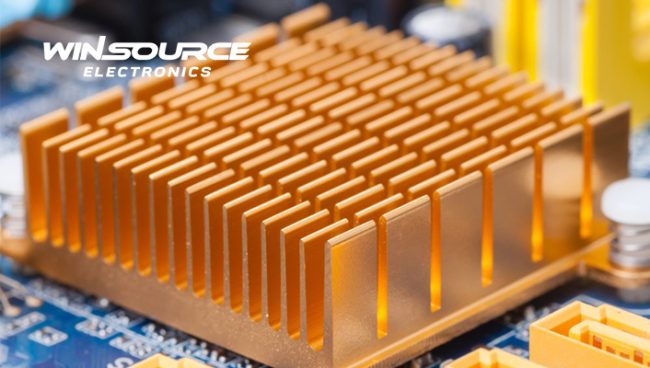

A heat sink serves as a critical element in the thermal management of electronic devices. Its primary function is to effectively dissipate the heat generated during the operation of electronic components. Typically constructed from thermally conductive materials such as aluminum or copper, a heat sink facilitates the transfer of heat away from the electronic elements.

This process is crucial to prevent overheating, as excessive heat can impair the performance and longevity of electronic equipment. In essence, the heat sink acts as a silent guardian, ensuring that electronic devices operate within their optimal temperature range and remain fully functional.

How Does a Heat Sink Work?

A heat sink functions through the principles of conduction, convection, and radiation to efficiently dissipate heat generated by electronic components.

Conduction:

Heat is transferred from the hot electronic components to the heat sink through direct contact. The heat sink, typically made of thermally conductive materials, like aluminum or copper, acts as a bridge between the source of heat (e.g., a CPU or GPU) and the surrounding environment. The high thermal conductivity of these materials allows for effective heat transfer from the electronic component to the heat sink.

Convection:

Once the heat is conducted to the heat sink, convection comes into play. Airflow is generated around the heat sink through the use of fans or natural convection. This airflow facilitates the transfer of heat from the heat sink’s surface to the surrounding air. The movement of air helps to carry away the heat, cooling the heat sink in the process. This convective heat transfer is a crucial aspect of a heat sink’s effectiveness.

Radiation:

In addition to conduction and convection, radiation also plays a role. A heat sink emits thermal radiation in the form of electromagnetic waves. This radiation carries away some heat energy, although it is typically less significant in comparison to conduction and convection. The heat sink’s design and surface properties can impact its radiative cooling capacity.

To optimize heat dissipation, heat sinks are designed with various features such as fins and heat pipes. Fins increase the surface area for improved convection, while heat pipes can enhance heat spreading within the heat sink. Proper installation and contact between the electronic component and the heat sink are critical to ensure efficient heat transfer.

In simple words, a heat sink operates by receiving heat through conduction, dissipating it via convection, and emitting a small portion through radiation. This process allows electronic devices to maintain safe operating temperatures and ensures their reliable performance.

What Does a Heat Sink Do When Electronics Overheat?

When electronics overheat, a heat sink plays a pivotal role in mitigating the adverse effects of excessive heat.

Here’s what a heat sink does when electronics overheat:

Absorbs Heat:

The primary function of a heat sink is to absorb and collect the heat generated by electronic components. It provides a conductive pathway for the heat to move away from the overheating element, usually a CPU, GPU, or other semiconductor devices.

Dissipates Heat:

Once the heat is absorbed, the heat sink is designed to increase the surface area available for heat dissipation. This is often achieved through the use of fins or other extended structures. The enlarged surface area enhances the transfer of heat from the heat sink into the surrounding air.

Regulates Temperature:

As the heat is transferred from the electronic component to the heat sink, the temperature of the overheating component begins to decrease. This cooling effect helps maintain the electronic device within its safe operating temperature range.

Prevent Damage:

Overheating can lead to a range of problems, including reduced performance, system instability, and even permanent damage to electronic components. The heat sink’s quick response to heat buildup helps prevent these issues by keeping temperatures in check.

Prolongs Lifespan:

Continuous exposure to high temperatures can significantly reduce the lifespan of electronic components. By preventing overheating, heat sinks contribute to the longevity and reliability of electronic devices.

Enhances Performance:

When electronics operate within their specified temperature limits, they can maintain their performance levels consistently. Heat sinks help ensure that the electronic components perform optimally under demanding conditions.

Offers Safety:

Overheating electronics can pose safety hazards, such as the risk of fires or component failure. Heat sinks mitigate these risks by keeping temperatures under control and reducing the likelihood of thermal-related accidents.

Energy Efficiency:

Cooler electronics generally consume less power and operate more efficiently. Heat sinks contribute to energy savings by allowing devices to function at lower temperatures, which can be especially important in energy-conscious applications.

Exploring the Key Components of a Heat Sink

Base Plate:

The base plate is the foundation of the heat sink. It is in direct contact with the heat source, such as a CPU or GPU. To maximize heat transfer, the base plate is usually made from materials with high thermal conductivity, like copper or aluminum. The smoothness and flatness of the base plate are critical for ensuring efficient contact with the heat source.

Fins:

Fins are thin, protruding structures attached to the base plate. They serve to increase the surface area of the heat sink, promoting better heat dissipation through convection. The design and spacing of the fins are carefully engineered to optimize airflow and heat transfer.

Heat Pipes:

Heat pipes are often integrated into heat sinks to improve heat distribution. These pipes contain a working fluid that evaporates at the hot end and condenses at the cooler end, effectively transporting heat to regions with more efficient heat dissipation. They enhance the overall thermal performance of the heat sink.

Mounting Hardware:

Heat sinks are securely attached to electronic components through mounting hardware. This hardware includes screws, clips, or retention brackets. Proper attachment ensures good contact between the base plate and the heat source, maximizing thermal conductivity.

Fans or Heat Sinks:

In active cooling systems, fans or additional heat sinks may be employed. Fans create airflow, enhancing the heat sink’s convective cooling capabilities. Larger heat sinks with fins can operate passively in natural convection, while fans are essential for high-power applications.

Thermal Interface Material (TIM):

TIM is a layer applied between the base plate of the heat sink and the heat source. It fills microscopic gaps and imperfections, ensuring better thermal contact and efficient heat transfer. Common TIM materials include thermal paste or thermal pads.

Extruded or Forged Heat Sink:

The manufacturing method used to create the heat sink can impact its performance. Extruded heat sinks are produced by pushing material through a mold, creating a simpler and cost-effective design. Forged heat sinks are made by forging or shaping metal to achieve more complex and customized shapes, potentially offering improved thermal performance.

Coatings and Surface Treatments:

Some heat sinks are coated or treated to enhance their thermal and corrosion resistance properties. For example, anodizing or nickel plating may be applied to the surface to improve durability and heat transfer efficiency.

Heat Sink Applications: Where Are They Used?

Computing Devices: Heat sinks are widely used in computers and laptops to dissipate heat generated by central processing units (CPUs), graphics processing units (GPUs), and other components. They play a critical role in preventing these devices from overheating, which can lead to performance degradation and component damage.

LED Lighting:

Light-emitting diodes (LEDs) generate heat while producing light. Heat sinks are employed to maintain optimal operating temperatures for LEDs, extending their lifespan and ensuring consistent light output.

Power Electronics:

In applications like power inverters, amplifiers, and voltage regulators, heat sinks are essential to manage the heat generated by electronic components. They enable efficient operation and safeguard against thermal stress.

Automotive Electronics:

Modern vehicles contain numerous electronic components, including engine control units (ECUs), infotainment systems, and power electronics. Heat sinks are utilized to manage the heat produced by these components, ensuring reliable performance and longevity.

Telecommunications:

Heat sinks are used in telecommunications equipment, such as routers, switches, and transmitters. These components generate heat during operation, and heat sinks are employed to prevent overheating and maintain consistent functionality.

Medical Devices:

Many medical devices, such as MRI machines, X-ray equipment, and laser systems, produce significant heat. Heat sinks help maintain the required operating temperature and ensure the reliability of these critical devices.

Solar Inverters:

Solar inverters convert direct current (DC) from solar panels into alternating current (AC) for use in homes and businesses. Heat sinks are used to manage the heat generated during this conversion process, optimizing energy efficiency.

Industrial Automation:

In industrial settings, automation and control systems can generate substantial heat. Heat sinks are applied to maintain proper operating temperatures and ensure uninterrupted industrial processes.

Heat sinks play a crucial role in maintaining the temperature of electronic devices, preventing overheating, and ensuring their proper functioning.

When it comes to finding high-quality heat sinks, WIN SOURCE deserves a special shout-out. They are known for offering some of the best heat sinks on the market, making it easy for individuals and businesses to keep their electronic components cool and efficient.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS