*Image from the internet; all rights belong to the original author, for reference only.

Diamond Foundry Begins Volume Production of Single-Crystal Diamond in Europe: A New Shift in the Global Semiconductor Materials Landscape

Europe has sent a strong signal to the global semiconductor industry.

The Spanish government has approved a €753 million investment—backed by the European Union—to support Diamond Foundry’s (DF) new single-crystal diamond (SCD) wafer facility in Trujillo. The plant aims to produce semiconductor-grade diamond substrates at industrial scale, marking the first project of its kind in Europe and one of the most ambitious SCD manufacturing programs worldwide.

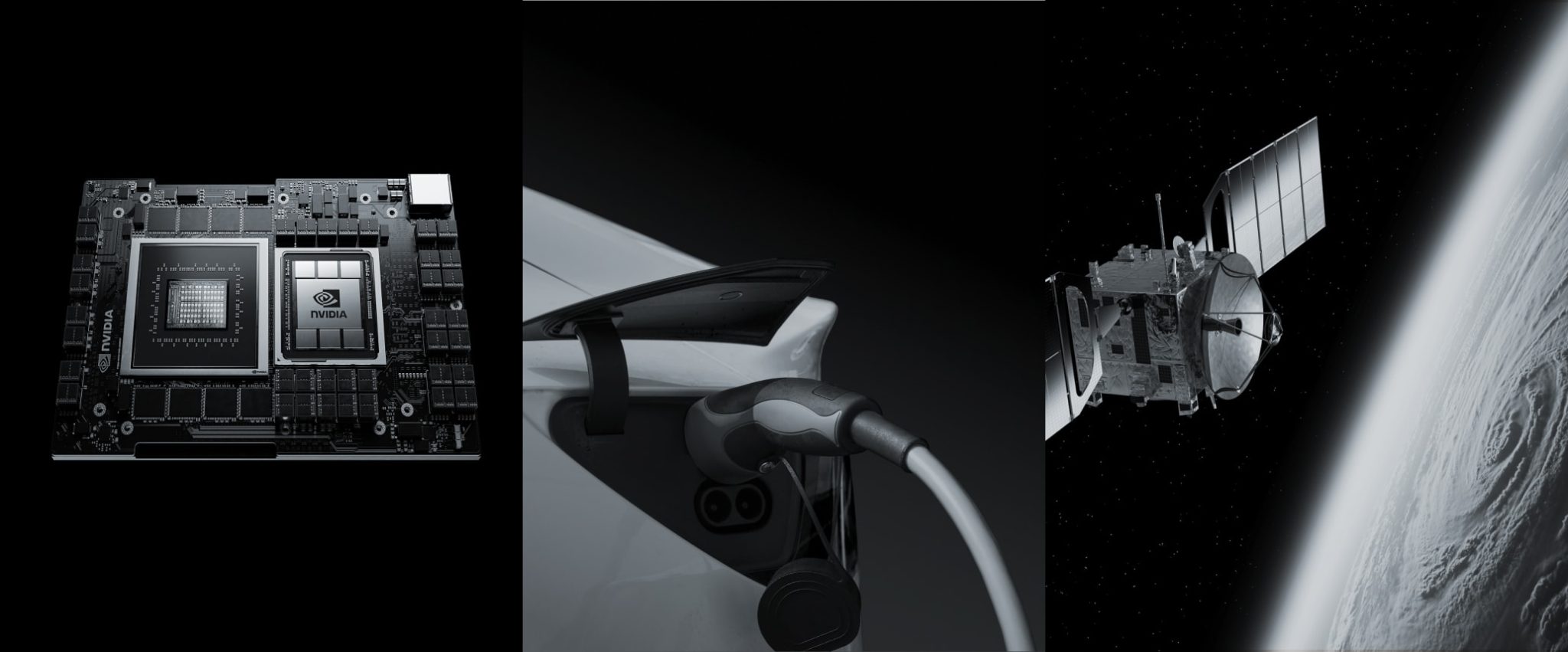

As AI accelerators, HPC processors, SiC power devices, and GaN RF amplifiers continue to push thermal density to unprecedented levels, materials rather than transistors are becoming the new bottleneck. Diamond Foundry’s move brings the industry closer to a long-awaited possibility: diamond wafers transitioning from laboratory prototypes to the semiconductor supply chain.

Q1: Why are single-crystal diamond wafers becoming a global hotspot now?

Diamond’s rise has nothing to do with novelty and everything to do with physics.

Over the past decade, high-power and high-performance devices have rapidly approached the thermal limits of silicon and even SiC. AI training accelerators, automotive traction inverters, 5G/6G power amplifiers, and data-center processors all generate heat far faster than conventional substrates can dissipate.

For example, 1200 V SiC MOSFETs such as the Wolfspeed C3M0032120K or ROHM SCT3030AL often encounter rapid junction-temperature growth under high current pulses. Diamond—offering thermal conductivity above 2000 W/m·K—removes heat far more efficiently, allowing these devices to sustain higher loads at lower temperatures.

In RF power, the same challenge appears. High-frequency GaN PAs like Qorvo’s QPA2212 face thermal compression at mmWave bands. Diamond provides a significantly shorter and more efficient heat-removal path.

SCD wafers enter the spotlight because the industry urgently needs a substrate that can unlock performance gains no longer achievable through lithography or packaging alone.

Q2: How is a diamond substrate fundamentally different from traditional thermal materials?

Conventional thermal materials—whether graphite sheets, AlN, Si₃N₄, or metal-based substrates—sit outside the active device. They help extract heat from the package but do not influence the thermal flow inside the transistor itself.

A diamond substrate changes the entire structure.

If the active device sits directly on diamond—such as a GaN HEMT grown or bonded on SCD—the heat path shortens dramatically. Compared with a GaN-on-SiC PA such as Qorvo’s QPA2933, a GaN-on-Diamond structure reduces thermal resistance at the junction and enables higher power density within the same footprint.

Beyond thermal conductivity, diamond offers excellent electrical insulation, mechanical rigidity, and radiation tolerance, making it highly suitable for aerospace, radar, and extreme-temperature applications.

In short, diamond does not “improve cooling.”

It redefines thermal behavior at the substrate level.

Q3: What breakthroughs allowed Diamond Foundry to industrialize SCD wafers?

For decades, SCD wafers struggled to scale due to small sizes, low yields, and limited compatibility with semiconductor processes. Diamond Foundry has overcome these barriers through several key innovations.

- Achieving 100 mm single-crystal wafers

DF’s ability to produce 100 mm, ~100-carat single-crystal diamond wafers is a landmark achievement. For the first time, diamond approaches the processable dimensions of SiC and can enter existing wafer-equipment flows. - Atomic-level bonding technology

DF’s atomic bonding enables ultra-thin semiconductor layers to attach directly to diamond.

This approach opens a real possibility for future AI processors to replace silicon baseplates with diamond. Power-delivery components used around CPUs and GPUs—such as the Infineon TDA21240—would benefit significantly from reduced thermal resistance at the substrate interface. - Scalable plasma-based CVD reactors

Diamond Foundry uses industrial-scale plasma reactors that allow faster growth and improved uniformity, addressing the reproducibility challenges that stalled diamond programs in the past.

Combined, these innovations form a manufacturable SCD wafer stack, turning diamond from a niche cooling material into a candidate for next-generation semiconductor substrates.

Q4: Which components and device categories will benefit first?

Devices that are highly sensitive to thermal resistance will be the earliest beneficiaries.

In IGBT modules, products such as the Infineon IKW40N120H3 often face rapid temperature spikes under transient overloads. Diamond substrates can significantly slow junction-temperature rise, improving reliability in electric-vehicle inverters and industrial drives.

In SiC MOSFETs, 1200 V devices used in traction inverters—such as ST’s SCTW35N120G2V—can operate at higher switching frequencies with diamond underneath, because thermal limits no longer cap performance as tightly.

In GaN RF power amplifiers, GaN-on-Diamond is expected to become a new premium route. High-frequency PAs like the Qorvo QPA family or Wolfspeed CGHV devices could achieve higher output power and lower thermal compression.

In AI/HPC systems, improved thermal spreading from a diamond substrate enables high-current power stages—such as the Renesas ISL99390—to operate with lower temperature rise, giving GPUs and HBM memory stacks more thermal headroom.

Diamond’s impact is therefore system-wide, not limited to one product type.

It reshapes the entire power-density chain.

Q5: Will diamond wafers reshape global semiconductor materials roadmaps?

Diamond will not replace silicon, SiC, or GaN. But it is emerging as the next-tier material for applications that can no longer scale through traditional substrates.

In RF, GaN-on-Diamond may challenge the dominance of GaN-on-SiC.

In power electronics, SiC modules on diamond bases may enable higher switching frequencies and higher current densities.

In AI/HPC, diamond-enhanced thermal spreading could redefine how GPUs and high-bandwidth memory modules are packaged.

This shift expands the materials landscape from “silicon-based enhancements” to “thermal-driven materials engineering.” Diamond’s entry into mass production makes this evolution tangible.

Q6: How will this development influence global semiconductor competition?

Diamond Foundry’s industrialization of SCD wafers in Europe gives the EU a strategic foothold in advanced substrate materials for the first time.

The move positions Europe alongside the U.S. in pushing next-generation thermal technologies, while Japan and the U.S.—already leaders in SiC and GaN—must now account for a new materials competitor.

As AI, EVs, and satellite communications continue to increase power density, access to diamond-based substrates may become a competitive advantage. Semiconductor innovation is shifting from pure lithography competition to a deeper contest around materials and thermal physics.

Diamond is entering this race at the exact moment when the industry needs it most.

Conclusion

Diamond Foundry’s decision to begin volume production of single-crystal diamond wafers in Europe signals a meaningful change in the semiconductor materials landscape. As AI accelerators, SiC power modules, GaN RF amplifiers, and high-bandwidth memory systems continue to raise thermal demand, diamond substrates offer the strongest route toward extending power density and device reliability.

Over the next decade, the performance ceiling of advanced semiconductors may be set not by transistor geometry but by how well materials manage heat.

With SCD wafers moving into production, diamond is no longer a theoretical option—

it is becoming a practical foundation for the next era of high-power, high-performance electronics.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS