* Question

What is the zero drift of the strain gauge?

* Answer

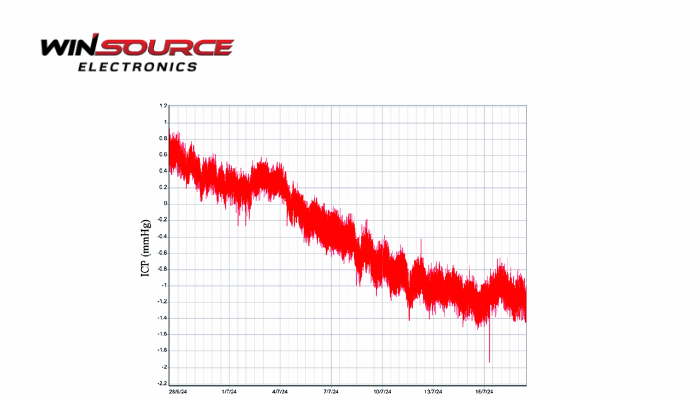

Zero drift in a strain gauge refers to a gradual, undesired change in the output signal when no actual strain is applied. In other words, even though the physical strain is zero, the gauge output changes over time, which can cause measurement inaccuracy and baseline offset in long-term monitoring.

Table of Contents

ToggleWhat Causes Zero Drift?

Zero drift can be caused by several factors, often related to environmental changes, material properties, or circuit instability:

1. Temperature Variations

Thermal expansion of the gauge material or substrate may cause a change in resistance, even without strain.

Differential expansion between the gauge and the bonded material induces pseudo-strain.

2. Material Creep

Over time, the adhesive or carrier material of the strain gauge may deform slowly under load or temperature, causing a shift in zero point.

3. Electrical Instability

Fluctuations in power supply, amplifier offset, or reference voltage in the Wheatstone bridge circuit can cause the baseline output to shift.

4. Humidity and Moisture Ingress

Moisture can alter the resistance of the strain gauge or the insulation, affecting baseline readings.

5. Gauge Self-Heating

The current used for signal acquisition (bridge excitation) may cause self-heating, especially in poorly ventilated environments, resulting in resistance drift.

How Is Zero Drift Detected?

By periodically reading the strain gauge output under known-zero strain conditions, any deviation from the original zero indicates drift.

Drift is often tracked using calibration routines or reference sensors.

How to Minimize or Compensate Zero Drift

1. Temperature Compensation

Use a dummy gauge or a half/full-bridge configuration to cancel thermal effects.

Select temperature-compensated strain gauges matched to the substrate material.

2. Stable Circuit Design

Employ precision op-amps, low-drift ADCs, and regulated power supplies.

Shield circuits from EMI and use twisted-pair cables.

3. Environmental Protection

Encapsulate gauges with protective coatings to resist moisture and corrosion.

4. Regular Recalibration

Perform zero-balancing or software offset correction at regular intervals or upon startup.

Summary

Aspect | Description |

What it is | Unintended baseline shift in strain gauge output when no strain is applied |

Main causes | Temperature, material creep, humidity, electrical instability |

Impacts | Measurement error, inaccurate readings, false strain indications |

Solutions | Temperature compensation, stable electronics, protection, recalibration |

COMMENTS