* Question

What is the combination of gasoline electromechanical control injection technology?

* Answer

The combination of gasoline electromechanical control injection technology refers to an integrated system that combines both electrical and mechanical components to precisely control the injection of fuel into the engine’s combustion chamber. This system is designed to optimize engine performance, fuel efficiency, and emissions. It typically combines the benefits of electronic control with mechanical fuel injection mechanisms.

Here’s an overview of the key components and how they work together:

Table of Contents

Toggle1. Electronic Control Unit (ECU):

The ECU is the brain of the system. It uses sensors to monitor variables like air-fuel ratio, engine temperature, throttle position, and exhaust gas content. Based on this data, the ECU adjusts the fuel injection process to ensure optimal engine operation.

The ECU controls the timing and duration of fuel injection, allowing for precise control of fuel delivery, which is crucial for optimizing performance, fuel economy, and emissions.

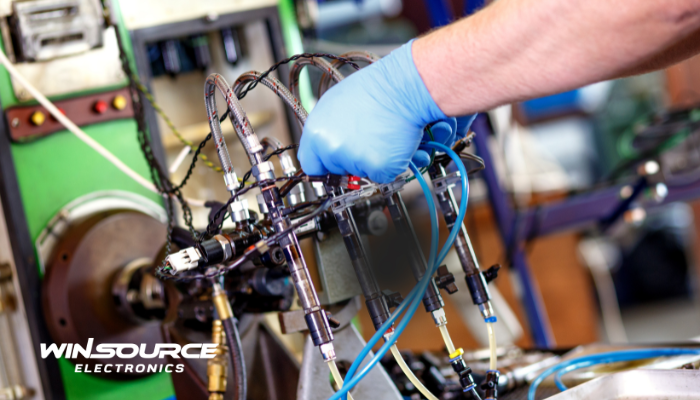

2. Fuel Injectors:

The fuel injectors are mechanical components that spray fuel into the combustion chamber. In electromechanical systems, these injectors are electronically controlled, meaning the ECU sends electrical signals to the injectors to open and close them at the right time and for the right duration.

The injectors can be of different types, such as port fuel injectors (PFI) or direct injectors (DI), depending on the engine design. Direct injection systems spray fuel directly into the combustion chamber, while port injection systems spray fuel into the intake manifold.

3. Sensors:

Various sensors monitor engine parameters and provide real-time data to the ECU. Common sensors in gasoline electromechanical control injection systems include:

Mass Air Flow (MAF) sensor: Measures the amount of air entering the engine.

Oxygen (O2) sensors: Monitor the oxygen content in the exhaust gases, helping the ECU adjust the air-fuel ratio.

Throttle Position Sensor (TPS): Indicates the position of the throttle, helping to determine the load on the engine.

Crankshaft and Camshaft Position Sensors: These sensors provide timing data, crucial for fuel injection and ignition timing.

4. Fuel Pump and Fuel Rail:

The fuel pump delivers fuel from the tank to the injectors at the correct pressure. The fuel rail distributes the fuel evenly to the injectors.

Both components must maintain a consistent fuel pressure for the system to work efficiently.

5. Actuators and Valves:

Actuators in the injectors or fuel rail work in tandem with the ECU signals to control the flow of fuel. These actuators ensure that the injectors open at the correct time and for the right duration based on engine needs.

Working Principle:

The combination of electrical and mechanical elements allows for precise fuel injection. The ECU processes inputs from various sensors and uses this data to control the injectors.

For example, at low engine speeds, the ECU might inject a smaller amount of fuel, while at high speeds or under heavy load, the fuel injection is increased.

Additionally, the system can adjust the air-fuel ratio in real-time to ensure efficient combustion, minimize emissions, and improve fuel economy.

Advantages of Gasoline Electromechanical Control Injection Technology:

Improved Fuel Efficiency: By precisely controlling fuel delivery, the system ensures that the engine only receives the necessary amount of fuel, improving overall fuel economy.

Lower Emissions: The system helps achieve the optimal air-fuel ratio, which results in cleaner combustion and reduced exhaust emissions.

Better Performance: The system allows for fine-tuned control over engine operation, leading to smoother acceleration, improved throttle response, and more consistent power output.

Adaptability: The electronic control allows the system to adapt to changing driving conditions and engine load, ensuring optimal performance at all times.

In summary, gasoline electromechanical control injection technology combines electronic controls (ECU and sensors) with mechanical injectors to precisely manage fuel delivery, optimizing engine performance, fuel efficiency, and emissions. This technology is a cornerstone of modern gasoline engine management systems.

COMMENTS