* Question

What are the electronically controlled ignition devices?

* Answer

Electronically controlled ignition devices are part of modern automotive ignition systems that use electronic circuits, usually controlled by an engine control unit (ECU), to manage the timing and firing of the spark plugs. These systems are designed to replace traditional mechanical and distributor-based ignition systems with more precise and programmable control mechanisms. Here are some key types and components of electronically controlled ignition systems:

1. Electronic Ignition System (EI):

– Breakerless Ignition Systems: These use a magnetic or hall-effect sensor to detect engine position and speed, eliminating the need for traditional contact breaker points.

– Capacitive Discharge Ignition (CDI): This system uses a capacitor’s rapid discharge to generate a high-voltage spark, which is ideal for quick firing and can handle high RPMs effectively.

2. Distributorless Ignition System (DIS):

– Also known as direct ignition, DIS does not use a conventional distributor. Instead, it uses multiple coils that are controlled electronically, each directly firing one or more spark plugs.

– This can either be a “waste spark” system, where each coil fires a pair of spark plugs simultaneously (one in the compression stroke and one in the exhaust stroke), or a coil-on-plug (COP) system where each spark plug has its own dedicated ignition coil.

3. Coil-On-Plug (COP) Ignition:

– Each spark plug has an individual coil directly sitting on top of it, controlled by the engine’s ECU. This setup allows for precise timing and can eliminate the need for spark plug wires.

– The ECU directly controls each coil, adjusting the ignition timing based on various engine parameters like speed, load, and temperature.

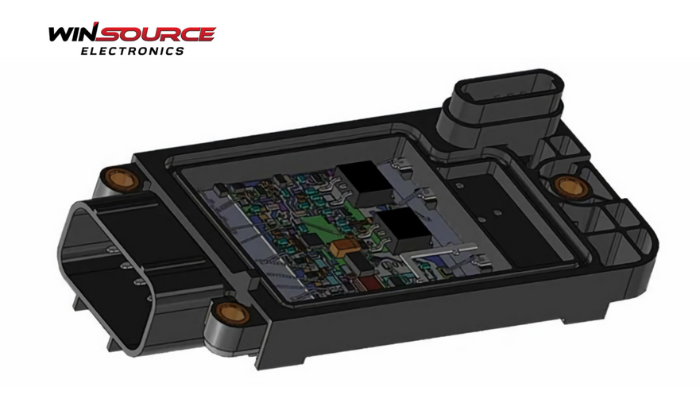

4. Ignition Control Module (ICM):

– A crucial electronic component in modern ignition systems, the ICM works with the ECU to control the timing and intensity of the spark based on sensor inputs about engine conditions.

5. Programmable Ignition Systems:

– These systems allow for custom settings of ignition curves and can be tuned specifically for different operating conditions or performance requirements. They are particularly popular in motorsports and customized performance vehicles.

Electronically controlled ignition systems provide several advantages over mechanical systems, including improved fuel efficiency, higher power output, reduced emissions, better cold starting, and lower maintenance. These systems can adapt the ignition process to changing engine conditions in real time, optimizing the engine’s performance across its operating range.

COMMENTS