* Question

What are the techniques for ladder programming?

* Answer

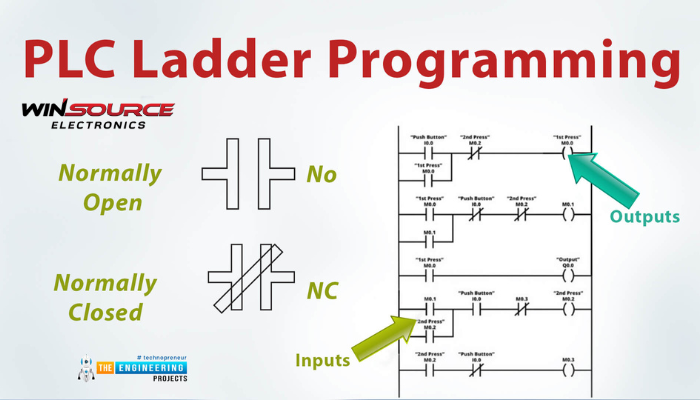

Ladder logic programming is a graphical programming language used primarily for industrial automation applications to program programmable logic controllers (PLCs). It’s designed to mimic electrical relay logic diagrams, making it intuitive for engineers familiar with relay controls. Here are some fundamental techniques and best practices for ladder programming:

Basic Techniques

1. Understanding Rungs and Rails:

– Rungs: Each rung represents a logical operation, where horizontal lines of the ladder function like electrical circuits.

– Rails: Vertical lines that provide power to the rungs, usually representing the power and ground or start and stop of the logic.

2. Using Contacts and Coils:

– Contacts: Represent inputs or conditions and can be normally open (NO) or normally closed (NC).

– Coils: Represent outputs or actions. When the conditions on the left (contacts) are met, the coil on the right is energized.

3. Common Instructions:

– XIC (Examine if Closed): Checks if the input/contact is true.

– XIO (Examine if Open): Checks if the input/contact is false.

– OTE (Output Energize): Activates an output when its rung goes true.

Advanced Techniques

1. Timers and Counters:

– Timers can delay actions or count the duration of events.

– Counters can keep track of occurrences and execute actions after a certain number of events.

2. Data Handling:

– Use of registers for data storage and manipulation.

– Move, compare, and compute data using specific instructions.

3. Master Control Rungs:

– Use master control or master control relays to control the execution of blocks of logic under specific conditions.

4. Subroutines and Jump Instructions:

– Organize code into manageable blocks.

– Use subroutines for repeated operations or tasks, reducing redundancy.

– Jump instructions to skip over certain sections of logic based on conditions.

Best Practices

1. Keep It Simple:

– Design logic that is easy to understand and maintain.

– Avoid overly complex rungs; break them into simpler, multiple rungs if necessary.

2. Commenting and Documentation:

– Thoroughly comment the logic to explain what each rung does.

– Maintain up-to-date documentation that matches the ladder logic.

3. Testing and Simulation:

– Use simulation tools to test the ladder logic before deploying it on physical PLCs.

– Ensure thorough testing to catch and correct errors.

4. Safety and Redundancy:

– Include safety interlocks and redundancies to prevent unsafe conditions.

– Ensure that the logic handles all possible states to avoid unintended operations.

Ladder programming is widely used in manufacturing, processing, and other industrial sectors due to its straightforward visual style and robust capabilities. It’s crucial for automation engineers to master these techniques to effectively design, debug, and maintain systems.

COMMENTS