PBC linear bearings are a game-changer, revolutionizing machine performance with their unmatched durability, precision, and adaptability. You’re about to uncover how they transform machinery’s efficiency and capabilities, ensuring unparalleled performance across various industrial applications.

Longevity Through Superior Design

PBC linear bearings epitomize longevity and consistent performance, primarily due to their meticulously engineered design. They are crafted to withstand prolonged use without compromising efficiency or accuracy.

This durability is a cornerstone feature, particularly in industrial motion control and high-performance linear systems, where the longevity of components directly impacts overall productivity and operational cost-effectiveness.

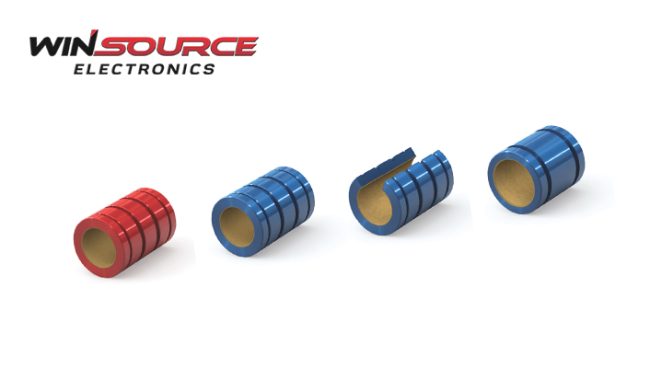

Material Innovation: The choice of materials in PBC linear bearings is pivotal in their longevity. By utilizing advanced materials that offer resistance to wear and tear, these bearings maintain their functional integrity over extended periods.

This material selection is crucial in precision linear guides and linear motion product databases, where each component’s lifespan significantly influences the system’s overall durability.

Structural Integrity: Beyond materials, the structural design of PBC Linear bearings ensures they can endure the rigors of industrial usage. The bearings are designed to maintain their form and functionality under various stressors, making them reliable components in custom linear solutions and PBC Linear motion systems.

Maintenance-Free Operation

Another aspect of PBC linear bearings that underscores their unmatched reliability is their maintenance-free nature. This characteristic is especially beneficial in sectors where challenging maintenance or downtime can have significant financial or operational consequences.

Self-Lubricating Technology: Many PBC linear bearings incorporate self-lubricating technology. This innovation reduces the need for regular maintenance and ensures that the bearings operate smoothly over time, a critical factor in industrial motion control systems.

Design for Reduced Wear: The bearings are engineered to minimize internal friction and wear, which are common causes of mechanical component maintenance needs. By reducing these factors, PBC Linear ensures that its bearings require less frequent servicing, making them ideal for applications in PBC Linear actuators and linear rails where maintenance access might be challenging.

Adaptability to Various Environments

PBC Linear bearings are durable, remarkably adaptable, and capable of performing under various environmental conditions. This adaptability is crucial for applications across diverse sectors, from standard manufacturing environments to more challenging situations.

Resistance to Environmental Stressors: Whether exposed to dust, moisture, or other contaminants, PBC linear bearings are designed to resist environmental stressors. This resistance is crucial in maintaining performance in environments where such factors are prevalent.

Temperature and Corrosion Resistance: The bearings can operate effectively in various temperature ranges and resist corrosion, a key attribute for industrial motion components exposed to harsh or varying environmental conditions.

Engineering for Exacting Requirements

High-Precision Design: The design of PBC Linear bearings is centered around achieving the highest level of precision. This is crucial in sectors like manufacturing, where even the slightest deviation can lead to significant errors. The accuracy of these bearings is achieved through advanced manufacturing techniques and stringent quality control measures.

This exactness is indispensable in applications like PBC Linear actuators and high-performance linear systems, where precision directly influences the system’s efficacy and reliability.

Material Selection and Manufacturing: The materials used in PBC Linear bearings are selected for their properties that contribute to precision, such as stability and minimal thermal expansion.

The manufacturing process, including precision machining and finishing, further ensures that each bearing meets the rigorous standards for precise linear motion.

Consistency in Performance

Reliable Accuracy under Varying Conditions: One of the standout features of PBC Linear bearings is their ability to maintain accuracy consistently, regardless of the operational conditions. This is a critical factor in industrial motion control and custom linear solutions, where bearings are expected to perform under varying loads, speeds, and environmental conditions.

The bearings’ design and material composition allows them to resist changes in performance due to external factors, ensuring reliability in diverse applications.

Adaptability to Different Systems: PBC Linear bearings are precise, accurate, and versatile. They can be integrated into various linear motion systems without losing their precision, including PBC Linear rails and motion components. This adaptability makes them a preferred choice for designers and engineers looking for reliable parts for their linear motion product database.

Technological Integration and Innovation

Incorporating Advanced Technologies: Integrating advanced technologies further enhances the precision and accuracy of PBC linear bearings. This includes computer-aided design and manufacturing processes, which allow for the creation of bearings with extremely tight tolerances. These technologies ensure that the bearings are not only precise but also consistent in their performance.

Custom Solutions for Specific Needs: PBC Linear understands that different applications may have unique requirements. Therefore, they offer customized linear solutions, where bearings are tailored to meet specific precision and accuracy needs. This approach ensures that PBC Linear bearings can deliver the required performance regardless of the application, whether in specialized machinery or standard equipment.

Prioritizing Safety in Design and Application

Safety-Centric Design Philosophy: PBC Linear’s approach to bearing design is based on a commitment to safety.

This is evident in the careful selection of materials, precision in manufacturing processes, and rigorous testing protocols. The bearings are designed with an understanding that they will be used in sensitive applications, necessitating a focus on minimizing risk and enhancing operational safety.

This approach ensures that PBC Linear bearings are practical and safe for various applications, including high-performance linear systems and custom linear solutions.

Application in Sensitive Environments: PBC Linear’s safety-first approach extends to the bearings’ application in sensitive environments. This is particularly important in industries where safety is non-negotiable, such as medical equipment, aerospace, and automated manufacturing systems.

The bearings are engineered to perform reliably and safely under these environments’ unique demands, reinforcing PBC Linear’s reputation as a safe, dependable motion solutions provider.

As you navigate the complexities of electronic components, remember that WIN SOURCE is your trusted ally. With an extensive database of parts, including those hard-to-find gems, we’re here to streamline your sourcing process.

Visit WIN SOURCE today to discover our inventory and experience seamless purchasing tailored to your unique needs. Your solution for electronic components is just a click away.

COMMENTS