Table of Contents

ToggleAC To DC Converter—Working, Conversion Methods & Applications

Since the invention of electric current, though, AC power has won the race. However, the mother of electric current is undoubtedly DC. There was a competition between AC and DC during the time of Edison and Nikola Tesla. Ultimately, Nikola Tesla’s Alternating Current (AC) won. He devised an AC-to-DC converter as one of Nikola’s great inventions. But the question arises, when DC power is generated foundationally, why prefer AC over DC? WIN SOURCE will address all these labyrinths through this knowledgeful blog. We are also a trusted partner with electric components for manufacturers and stakeholders. Our 100% genuine electronic parts are available with guaranteed reliability and durability.

Let’s Move Ahead In Pursuing The Concisely Detailed Article On AC To DC Converters.

Types of Electric Current

In the real world, two electric currents have been used for years. Alternating Current (AC) and Direct Current (DC). To go further with the AC-DC conversion devices, we will look at the fundamentals of these two electric currents.

What is an AC Power (Current)?

AC is the abbreviation used for Alternating Current. In short form, it is referred to as AC. It is a type of electric current that flows periodically, switching (changing) direction. In contrast with direct current (DC), alternating current travels between positive and negative directions in a continuous cycle. This oscillating movement goes like the rhythmic to-and-fro motion of a swinging pendulum.

Why AC Current is Preferred for Homes?–Application

AC power is the type of electricity typically delivered to our homes and used in everyday devices. Though it’s more efficient for long-distance transmission, power supply companies can preferably transform it to different voltage levels for various applications.

What is a DC Power (Current)?

DC stands for Direct current. It is a type of electric current that flows steadily and consistently in a single direction. As opposed to alternating current (AC), which oscillates back and forth, direct current maintains a constant flow of electric charge in one specific path. DC is a continuous, unchanging stream of current flowing in a circuit.

Why is DC Current Used in Many Appliances?–Application

DC power is commonly associated with batteries and electronic devices such as smartphones, medical instruments, and laptops. Thanks to providing a stable power source for various applications like electronics, vehicles, and low-voltage systems, this is a unique choice for power supply to these devices.

The most interesting part of DC power is that it can be saved in batteries, while AC power cannot. That is why we need the AC to DC converters. So, now your curiosity must have infused your eagerness to learn more about the converter.

What is an AC to DC Converter?

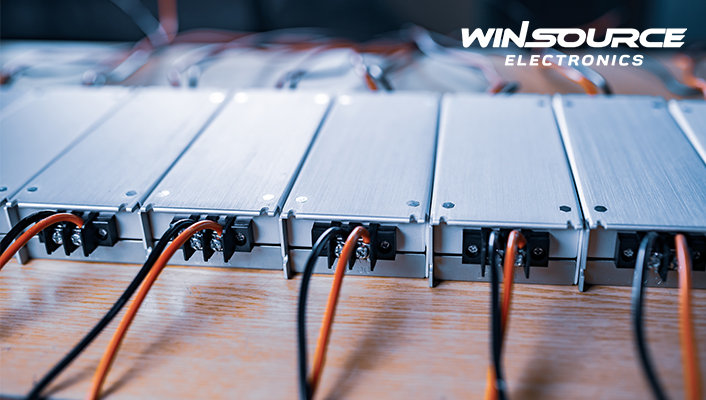

An AC-to-DC converter is an electrical device that changes the alternating current (AC) nature (electric charges) to the DC. The conversion to DC power takes place from AC input to DC output. The converted electric charges are stored in charge accumulation equipment such as batteries, dry cells, or other charge storage devices.

This conversion allows electronic devices to use the consistent and unidirectional power provided by direct current. The conversion of AC to DC is done with an electronic device like the MINT1400A2410L01 converter. The converted charge becomes suitable for various applications such as powering gadgets and charging batteries.

How Does AC-DC Conversion Take Place?–Working

It is fascinating to know how AC/DC Conversion takes place. There are two logical methods to convert Alternating Current to Direct Current. These two methods for AC-DC Conversion are:

· Transformer Conversion Method

· Switching Conversion Method

Transformer Method

In Transformer-Based AC/DC Conversion, a transformer converts the current nature. This AC/DC conversion involves a step-down transformer and rectifiers.

Here’s How The Process Works:

Step 1

AC Input: The alternating current (AC) input is connected to the primary winding of a step-down transformer.

Step 2

Transformer: The step-down transformer converts the higher voltage AC input to a lower voltage AC output. The secondary winding’s voltage is typically chosen based on the desired output voltage for the DC circuit. Resistors in the transformer are also used to control the flow of current.

Step 3

Rectification: The AC output of the transformer is then fed into a rectifier (NXP) circuit. The rectifier converts the AC voltage into a pulsating DC voltage, allowing only half of the AC waveform to pass through.

Step 4

Filtering: The pulsating DC voltage from the rectifier still contains ripples. To smoothen the voltage, a filter capacitor is connected across the output. This capacitor helps reduce the ripples by storing electric energy during the peak voltage and releasing it during the troughs of the voltage waveform.

2. Switching-Based AC/DC Conversion

Switching-based AC/DC conversion uses high-frequency switches (like transistors or thyristors) to switch the voltage on and off rapidly. Switching Conversion from AC to DC effectively converts the nature of the current by minimizing the charge drainage. The most acclaimed switching-based technique for Switching is the PWM (Pulse Width Modulation) technique.

Step 1

AC Input: The AC input is first rectified as in the transformer-based method, creating a pulsating DC waveform.

Step 2

High-Frequency Switching: A high-frequency switch (often a transistor or a thyristor) is used to chop the pulsating DC voltage into rapid pulses. The PWM controller controls the width of these pulses.

Step 3

Filtering: A filter circuit, usually consisting of an inductor and a capacitor, is used to smoothen the chopped pulses. The inductor helps to filter out high-frequency components, while the capacitor smoothens the voltage.

Step 4

PWM Control: The width of the pulses generated by the high-frequency switch is controlled by a PWM controller. The effectual voltage output can be controlled by adjusting the duty cycle (pulse width ratio to the time period).

Component for AC-DC Converter Manufacturing

The complex converter circuit requires specific electronic components such as filters, rectifiers, regulators, diode rectifiers, and capacitive transformer-less converters. WIN SOURCE supplies all the electronic elements required for AC to DC Converter manufacturing. We have won the trust of countless satisfied customers with our quality electro parts. Place your quotation and get the best deals from us.

COMMENTS