The aerospace industry consistently stands at the forefront of technological innovation, from commercial aviation to space exploration. Each advancement within the sector hinges on breakthroughs in electronic technology. As electronic components continue to advance in performance, we are poised at the brink of a new wave of technological transformation. From the navigation computers of the Apollo missions to today’s sophisticated automated flight systems, electronic technology has had a profound impact on aerospace.

Next-Generation Avionics

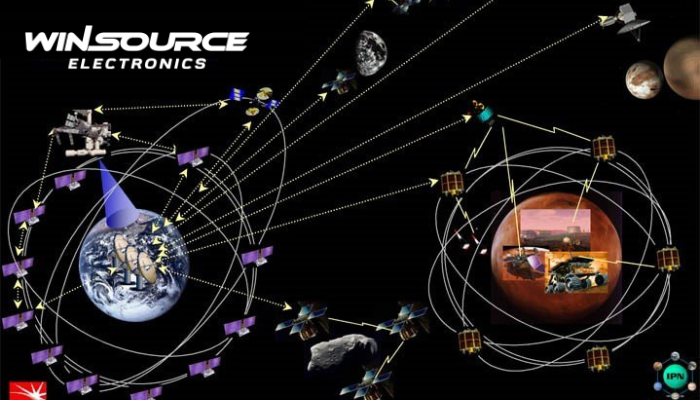

In the current aerospace realm, the complexity of electronic systems has reached unprecedented levels. These systems integrate high-precision sensors and advanced flight control technologies, as well as communications equipment capable of handling vast amounts of data—crucial for executing complex aerospace missions. Faced with challenges such as extreme temperatures, mechanical vibrations, and high radiation levels, there is an increased demand for enhanced performance and reliability in the electronic components of aircraft and spacecraft.

Driving Electrification

The aerospace industry is transitioning towards electrification, enhancing energy efficiency and promoting environmental sustainability. In this domain, new-generation solid-state devices like silicon carbide (SiC) and gallium nitride (GaN) power semiconductors are revolutionizing traditional power distribution and propulsion systems. These high-efficiency power electronics are being developed collaboratively by leading global aerospace manufacturers and semiconductor firms, such as the partnership between Airbus and STMicroelectronics, focusing on developing power electronics for future hybrid and all-electric urban air mobility platforms.

Challenges and Technical Demands

1.Adaptability to Extreme Environments: Spacecraft and aircraft undergo extreme temperature fluctuations during launch, and while in the vacuum of space or high-altitude conditions. Electronic components must function reliably under these extreme temperatures. Additionally, in the absence of Earth’s atmospheric protection in space, electronic devices are exposed to intense cosmic radiation. This requires components to have high radiation resistance to prevent radiation-induced errors and performance degradation.

2.Reliability and Lifespan: Aerospace missions are typically long-duration and involve high maintenance costs. Therefore, electronic components need to exhibit exceptional reliability and longevity to minimize the risk of failures during missions.

3.Lightweight and Miniaturization: Reducing weight is a crucial aspect of aerospace design, as launch costs are closely related to payload weight. Electronic components must be designed to be lighter and more compact, while maintaining or enhancing their functionality and performance.

4.High-Performance Requirements: Many aerospace missions require real-time data processing and high-speed communications. This necessitates that electronic components possess high-speed, efficient processing capabilities, and achieve this without significantly increasing power consumption.

5.Interference Resistance: Maintaining the stability of electronic systems in complex electromagnetic environments is vital. Electronic components must be designed to withstand interference from other devices.

These challenges have driven advances in materials science (such as high-temperature superconducting materials), semiconductor technology, and microelectronics, as well as rigorous testing and validation of electronic components to ensure they meet the specialized requirements of aerospace missions.

Supply Chain and Partnerships

Against a backdrop of continual technological progress, establishing a stable supply chain and deepening supplier relationships are crucial. WIN SOURCE, as a global leading distributor of electronic components, has developed a unique quality control system that includes packaging inspections, shipment label checks, visual product inspections, non-destructive testing, and strict adherence to precise environmental and humidity controls. Moreover, they continually optimize their supply chain system and expand global procurement channels to build an extensive international supply chain network, ensuring a stable supply of high-quality components to meet the needs of increasingly complex aerospace missions and support the success of space projects.

As the aerospace industry continues to evolve, the reliance on advanced electronic components is increasingly crucial. From enhancing flight safety and efficiency to achieving the grand objectives of space exploration, these components are the pillars of the technological leaps we are witnessing. Ongoing collaboration between aerospace engineers and electronic component suppliers is vital for addressing today’s challenges and unlocking future possibilities.

©2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS