Taking a Look at the MLCC Construction

Multilayer ceramic capacitors are constructed using layers of ceramic material interleaved with metal electrodes. The ceramic material typically used is barium titanate or a similar ferroelectric material, chosen for its high dielectric constant. The electrodes, often made of silver or nickel, are sandwiched between these ceramic layers.

The entire structure is then fired at high temperatures to create a monolithic block with multiple layers, each acting as a separate capacitor.

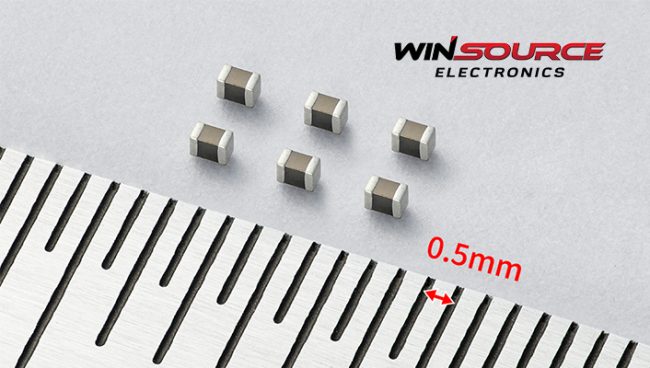

The key advantage of this construction lies in the high capacitance achievable within a small footprint, making MLCC ideal for miniaturized electronic devices.

Capacitance Density and Voltage Ratings

One of the defining features of MLCCs is their high capacitance density. This property is a result of the layered structure, enabling the capacitor to store more charge in a given volume compared to traditional capacitor designs.

Capacitance values can range from picofarads (pF) to microfarads (μF), accommodating a wide spectrum of applications.

Voltage ratings are critical considerations when selecting MLCCs for a particular application. MLCCs are available in a variety of voltage ratings, and choosing the right one is crucial to prevent capacitor breakdown or failure. It is essential to consider the maximum voltage the capacitor will experience in the circuit to ensure a safety margin.

Surface Mount Technology (SMT) and MLCCs

Surface mount technology (SMT) has become the standard in electronic manufacturing, offering efficiency, reduced component size, and enhanced reliability. MLCCs are a natural fit in SMT processes due to their compact size and compatibility with automated assembly.

SMT involves placing components directly onto the surface of a printed circuit board (PCB), as opposed to through-hole technology, which involves inserting components through holes in the PCB.

MLCCs, as surface mount devices (SMDs), simplify the assembly process, allowing for higher component density and improved signal integrity.

Dielectric Materials and Temperature Stability

The choice of dielectric materials significantly influences the performance of MLCCs. Barium titanate-based ceramics are popular due to their high dielectric constants, but different formulations and additives can be employed to tailor the characteristics of the dielectric. The dielectric material affects parameters such as temperature stability, loss tangent, and insulation resistance.

Temperature stability is a critical consideration, especially in applications where the operating environment experiences significant temperature fluctuations. X7R and X5R dielectrics are commonly used for applications requiring moderate temperature stability, while C0G (NP0) dielectrics offer high stability over a wide temperature range but often at the cost of reduced capacitance.

Effect of Aging and DC Bias

MLCCs are subject to aging effects, which can impact their capacitance over time. This phenomenon, known as DC bias or voltage coefficient, is particularly relevant in applications where the capacitor is exposed to a continuous bias voltage. Engineers must carefully account for these effects, especially in circuits where long-term stability is critical.

DC bias characteristics can vary among MLCCs, and manufacturers provide datasheets detailing the expected changes in capacitance under different bias conditions. Understanding these characteristics is essential for ensuring the reliability of circuits over extended periods.

Application-Specific Considerations

MLCCs find application in a diverse range of electronic devices, from smartphones and laptops to automotive electronics and medical devices. Each application may impose specific requirements on MLCC performance, necessitating careful consideration during component selection.

In power supply circuits, MLCCs are commonly used for filtering and decoupling to stabilize voltage levels and minimize noise. High-frequency applications, such as RF circuits, demand MLCCs with low equivalent series resistance (ESR) and low equivalent series inductance (ESL) to maintain signal integrity.

Advancements in MLCC Manufacturing Processes

Advancements in manufacturing processes have played a pivotal role in shaping the capabilities and characteristics of multilayer ceramic capacitors (MLCCs). As electronic devices continue to demand smaller footprints, higher capacitance, and improved performance, manufacturers are exploring innovative techniques to meet these evolving requirements.

Thin-Film Deposition Methods:

One notable area of progress in MLCC manufacturing is the use of advanced thin-film deposition methods. Thin films of ceramic materials are precisely applied to create the capacitor layers, allowing for tighter control over layer thickness and consistency. This level of precision contributes to enhanced capacitance and better performance.

Techniques like chemical vapor deposition (CVD) and physical vapor deposition (PVD) are gaining prominence, enabling manufacturers to achieve the fine layers essential for miniaturization.

Precision Laser Trimming:

Precision is paramount in MLCC design, and laser trimming has emerged as a key technology in achieving it. Laser trimming allows manufacturers to precisely adjust the capacitance of individual MLCCs during the production process. This level of customization ensures that MLCCs meet the exact specifications required for a particular application. By incorporating laser trimming into the manufacturing process, engineers can fine-tune capacitance values, resulting in better overall performance and reliability.

Automated Assembly Technologies:

Automation is a driving force in modern manufacturing, and MLCC production is no exception. Automated assembly technologies not only increase production efficiency but also reduce the risk of human error. Surface mount technology (SMT) machines, pick-and-place robots, and automated inspection systems have become integral to the MLCC manufacturing process.

These technologies enable the high-volume production of consistently high-quality MLCCs, contributing to the widespread availability of these components in the electronics market.

Smart Manufacturing Integration:

The integration of smart manufacturing technologies, including the Internet of Things (IoT) and data analytics, is transforming MLCC production. Real-time monitoring of manufacturing processes allows for proactive quality control and rapid identification of potential issues. This data-driven approach enhances overall production efficiency, reduces waste, and ensures that MLCCs meet the stringent quality standards required for various applications.

So, you see, multilayer ceramic capacitors (MLCCs) play a crucial role in modern electronics, offering a compact and efficient solution for energy storage and signal filtering. Their widespread adoption can be attributed to their high capacitance density, low equivalent series resistance (ESR), and excellent reliability.

WIN SOURCE stands out as a reliable source for MLCCs, providing a diverse range of products that cater to the ever-growing needs of the electronics industry. The availability of MLCCs with different voltage ratings, capacitance values, and form factors through WIN SOURCE ensures that designers and manufacturers can find the right components for their specific application

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS