A Printed Circuit Board (PCB) is essential in modern electronics. It provides a reliable and efficient way to connect electrical components, ensuring the proper functioning of various devices.

In this article, we will explore the various types of PCBs and delve into their composition to help you understand these critical electronic components.

Table of Contents

ToggleWhat Is A Printed Circuit Board?

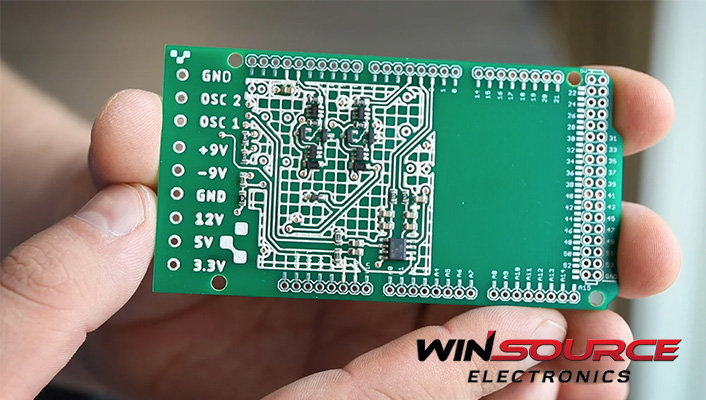

A printed circuit board (PCB) is also known as a printed wiring board or PWB. It is a board used to connect electrical components in a device. It has layers of conductive and insulating materials, with the conductive layers etched to create a pattern for the electrical connections.

Components are soldered onto the board to connect them electrically. PCBs come in different types and are essential for the proper functioning of electronic devices.

Types Of A Printed Circuit Board

Now that you know what a printed circuit board (PCB) is, let’s talk about the three common types of PCBs: single-sided, double-sided, and multilayer.

1. Single-sided PCB

Single-sided PCBs are the simplest type of PCB, with components on one side and wires on the opposite side. These boards are called “single-sided” because the wires are only visible on one side.

Single-sided boards are typically used in early circuits, as they have many limitations in circuit design since the wires must follow a specific route and cannot cross.

2. Double-sided PCB

Double-sided PCBs have wiring on both sides of the circuit board, with a “bridge” between the circuits called a “via.” A via is a small hole on the PCB that is filled or coated with metal and can have wires attached to it from both sides.

Double-sided PCBs have twice the area of single-sided PCBs, making them better suited for more complex circuits. They also eliminate the problem of wire interlacing that can occur with single-sided PCBs, as wires can be passed to the other side via holes.

3. Multilayer PCB

Multilayer PCBs take the concept of double-sided PCBs further by utilizing multiple layers of single or double-sided wiring boards.

The space available for circuit connections is expanded by alternating between insulating bonding substances and positioning systems.

Composition Of Printed Circuit Board

A typical PCB is composed of the following components:

Circuits and Diagrams

These are used as a tool to conduct between the components. The design will also have a large copper surface that serves as a grounding and power layer. The circuit and pattern are created at the same time.

Dielectric

Also known as the substrate, this component maintains insulation between the circuit and each layer.

Vias (Through Holes)

These allow for connecting lines from more than two layers. Larger through holes are used for component plug-ins, while non-through holes are often used for surface mounting.

Solder Mask

Not all copper surfaces need to be tinned. A material coating (often epoxy resin) is printed on the non-tin area to protect the copper surface from consuming tin.

This prevents short circuits between non-tinned lines. Different techniques separate the solder mask into green, red, and blue oils.

Marking/Legend/Silk Screen

This component is not necessary, but its primary purpose is to identify each item on the circuit board by name and location frame, which is useful for maintenance and identification after assembly.

Surface Finish

The surface of copper cannot be tinned because it is easily oxidized in the atmosphere, resulting in poor soldering qualities. The copper surface that needs to be tinned will be protected using various protection methods, including ENIG, HASL, Immersion Tin, Immersion Silver, and Organic Solder Preservative (OSP).

Conclusion

Printed circuit boards (PCBs) are essential components in modern electronics, providing a reliable and efficient way to connect electrical components. Understanding the different types of PCBs and their composition can help you choose the right board for your specific application.

And if you are thinking of bulk purchasing Printed circuit boards, then there’s no better supplier than WIN SOURCE. So, contact us right away.

COMMENTS