A cushioned clamp is a type of fastening device that is used to hold and secure objects in place. It consists of two parts – a band or strap and a screw or bolt. The band is wrapped around the object being secured, and the screw or bolt is tightened to hold it in place.

One of the key features of a cushioned clamp is its cushioned lining or padding, which helps to protect the object from damage and provides a secure grip. This is especially useful for delicate objects or materials that can easily be scratched or dented by traditional metal clamps.

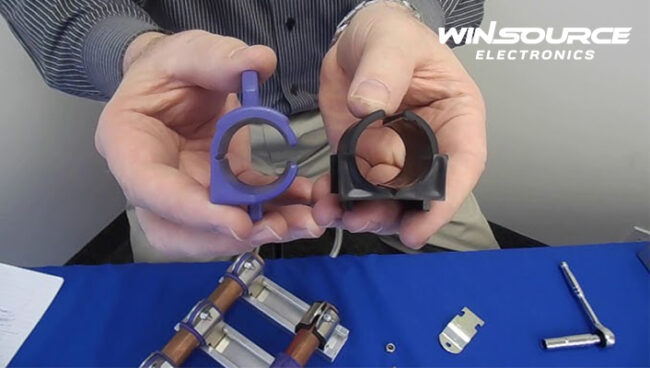

Speaking of clamps, CUSH-A-NATOR CN10 cushioned clamps are designed to ensure stability in dynamic environments. These clamps provide a secure hold on pipes, tubes, and cables while also reducing vibrations and noise.

When working in industries such as automotive, aerospace, or marine where there is constant movement and vibration, it is crucial to have a reliable and sturdy clamping solution. This is where CUSH-A-NATOR CN10 cushioned clamps excel – offering excellent performance in even the most challenging environments.

Let’s discuss the key features of CUSH-A-NATOR CN10 cushioned clamps and how they contribute to stability in dynamic environments.

Construction and Materials

The CUSH-A-NATOR CN10 Cushioned Clamp is meticulously crafted with precision, utilizing high-quality materials to deliver optimal performance in challenging conditions. The hardware comprises plated steel, providing robustness and corrosion resistance essential for prolonged usage in diverse environments. This ensures the longevity of the clamp, even when exposed to harsh elements.

The height of the CN10 stands at 1.54 inches, offering a balance between compactness and the capability to accommodate various tubing sizes effectively. Its length measures 1.62 inches, while the width is 1.06 inches, contributing to a design that strikes the right chord between versatility and structural integrity.

The insert material, a crucial component, is made from Thermoplastic Elastomer (TPE). TPE is chosen for its exceptional resilience, flexibility, and resistance to both high and low temperatures. This thermoplastic material acts as a cushion, providing a protective layer between the clamp and the tube it holds, effectively dampening vibrations and preventing potential damage to the tube.

Temperature Range And Resistance Properties

One of the standout features of the CN10 is its impressive temperature range. With the ability to withstand temperatures ranging from -50 degrees to 275 degrees, this cushioned clamp is well-suited for applications in extreme environments, where temperature variations are common.

The steel clamp and standard TPE cushion synergize to maintain stability and functionality across a broad spectrum of operating conditions.

Resistance to heat and vibration is paramount in dynamic environments. The CN10 excels in both aspects, making it an ideal choice for applications where components are subjected to continuous movement and varying temperatures.

This resistance not only ensures the longevity of the clamp but also safeguards the integrity of the components it secures.

Tube Size and Type

The CUSH-A-NATOR CN10 Cushioned Clamp is designed to accommodate tubes with a size of 5/8 inches. This specific sizing enhances the versatility of the clamp, catering to a wide range of applications across industries. The ‘Standard’ type designation signifies its universal application, making it suitable for various tubing materials and diameters within the specified size range.

Mounting Type and Features

The CN10 employs a Strut Clamp mounting type, offering a secure and stable attachment mechanism. Strut clamps are known for their robustness and reliability in industrial settings, providing a secure grip on structural elements. This mounting type enhances the overall stability of the CN10, making it an apt choice for applications where a firm and dependable connection is paramount.

Features That Set CN10 Apart: Pressure Control, Self-Alignment, and Thumb Drive

The CUSH-A-NATOR CN10 Cushioned Clamp distinguishes itself through a set of sophisticated features that not only ensure stability in dynamic environments but also simplify the installation process.

These features – Pressure Control, Self-Alignment, and Thumb Drive. These collectively contribute to the clamp’s exceptional performance and versatility.

Pressure Control

One of the standout features of CN10 is its advanced pressure control mechanism. This feature allows the clamp to exert just the right amount of force on the tube it secures, avoiding the pitfalls of over-tightening or inadequate grip.

Over-tightening can lead to stress concentrations and potential damage to the tube, while insufficient grip jeopardizes the stability of the entire assembly.

The pressure control feature addresses these concerns by providing a delicate balance, ensuring that the clamp maintains optimal pressure for effective vibration damping without compromising the integrity of the tubing.

Self-Alignment

In dynamic environments, where precise alignment may be challenging due to external forces or varying conditions, the CN10’s self-alignment feature comes to the forefront.

This adaptive mechanism allows the clamp to accommodate slight variations in tube placement without sacrificing its grip or stability.

Self-alignment ensures that the CN10 can effectively secure tubes even when conditions are less than ideal, making it a reliable choice in scenarios where components are subject to continuous movement or potential shifts in position.

Thumb Drive

Installation efficiency is a key consideration in industrial settings, where time is often a critical factor. CN10 addresses this concern with its innovative Thumb Drive feature, streamlining the installation process.

The Thumb Drive mechanism allows for quick and easy installation, reducing the time and effort required for engineers and technicians to secure the clamp in place.

This user-friendly aspect not only enhances the overall efficiency of projects but also minimizes the margin for error during installation, contributing to the reliability of the entire system.

Together, these features showcase the meticulous engineering that has gone into the design of CN10.

By combining pressure control for optimal grip, self-alignment for adaptability, and Thumb Drive for ease of installation, CUSH-A-NATOR has created a cushioned clamp that not only excels in stability but also addresses the practical challenges encountered in real-world applications.

Engineers and technicians benefit from the versatility of CN10, as it provides solutions to common issues faced in dynamic environments. Whether it’s ensuring a secure grip on a moving component, adapting to slight variations in tube placement, or expediting the installation process, CN10 stands out as a reliable and user-friendly choice.

When it comes to industrial applications, features like pressure control, self-alignment, and Thumb Drive position CN10 as a frontrunner in stability solutions, offering both precision and practicality.

Applications and Industry Relevance

The CUSH-A-NATOR CN10 Cushioned Clamp finds its application in a myriad of industries where stability and vibration control are paramount. From automotive and aerospace to industrial machinery and HVAC systems, the CN10 proves to be a versatile and reliable solution.

Its ability to withstand a wide temperature range, resist heat and vibrations, and accommodate different tube sizes positions it as a go-to choice for engineers seeking stability in dynamic environments.

So you see, CUSH-A-NATOR CN10 cushioned clamps serve as the perfect solution for stability in dynamic environments. These clamps are not only reliable and durable but also offer excellent cushioning to reduce noise and vibrations.

If you’re in search of high-quality clamps, WIN SOURCE can be the place to start with. As a trusted distributor of electronic components, Win Source offers a wide range of clamps and other electronic products to meet your industry needs.

COMMENTS