In high-current electrical systems, the use of shunt resistors plays a crucial role in measuring current flow accurately. Shunt resistors are employed to develop a voltage drop proportional to the current passing through them, enabling precise current measurement.

However, these components are not immune to power loss, which can affect the overall efficiency of the system.

Let’s learn about the various strategies and techniques for minimizing power loss in high-current shunt resistor applications.

Power Loss in High Current Shunt Resistor Applications

Power loss is a critical consideration in high-current shunt resistor applications, as it directly impacts the system’s efficiency and performance. Shunt resistors are commonly employed in various electronic circuits to measure current by producing a voltage drop proportional to the current passing through them.

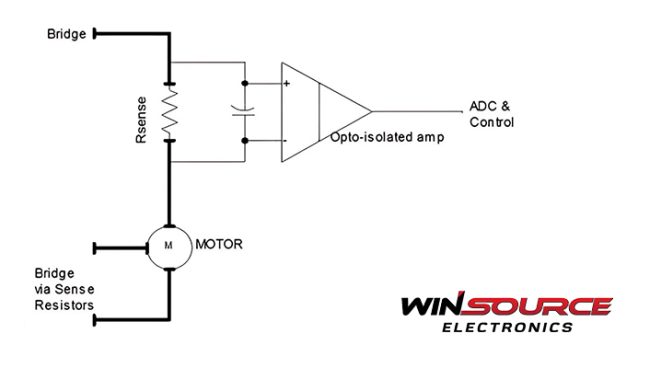

In applications involving high current, such as power electronics, motor drives, and energy management systems, the power dissipated in the shunt resistor can become a significant factor.

The power loss (P_loss) in a shunt resistor is primarily determined by the current flowing through it (I) and the resistance value (R), according to Ohm’s Law (P_loss = I^2 * R). In high-current scenarios, the power loss can escalate rapidly due to the squared relationship with current. This increase in power loss not only results in energy wastage but also leads to elevated temperatures in the shunt resistor.

One challenge in high-current applications is managing the thermal effects of power loss. The resistive element of the shunt resistor generates heat, and if not properly dissipated, it can adversely affect the accuracy and reliability of the current measurement and overall system performance. Excessive heat can lead to a shift in the resistor’s resistance value, potentially introducing errors in current sensing.

Engineers often employ various strategies to mitigate power loss and thermal issues in high-current shunt resistor applications, which are explained below.

Steps to Minimize Power Loss in High-Current Shunt Resistor Applications

Minimizing power loss in high-current shunt resistor applications requires a systematic and well-thought-out approach. Here are the essential steps to optimize efficiency and reduce energy wastage:

Step 1: Accurate Current Measurement

Using high-quality current measurement equipment ensures precise current measurement. Instruments should be calibrated regularly to maintain accuracy and prevent measurement errors that could lead to unnecessary power loss.

Step 2: Choose the Right Shunt Resistor

Select a shunt resistor with an appropriate power rating higher than the expected maximum dissipation. Opt for low-resistance shunt resistors to minimize voltage drop and power dissipation, but be mindful of striking a balance to prevent excessive current levels.

Step 3: Enhance Thermal Conductivity

Choose shunt resistors made from materials with excellent thermal conductivity, such as copper or high-conductivity alloys. Improved thermal conductivity facilitates efficient heat dissipation, reducing the risk of overheating and power loss.

Step 4: Implement Active Cooling

To maintain optimal operating temperatures, consider implementing active cooling techniques, such as forced air or liquid cooling. Active cooling helps dissipate excess heat, preventing overheating and minimizing power loss in high-current shunt resistor applications.

Step 5: Optimize Placement on the Circuit Board

Carefully plan the layout and placement of shunt resistors on the circuit board. Avoid crowded areas and ensure adequate spacing between components to promote proper airflow. This optimization minimizes thermal interference and contributes to efficient heat dissipation.

Step 6: Monitor Operating Conditions

Implement a robust monitoring system that tracks operating conditions, including temperature and current levels. Set up alerts for abnormal conditions to enable timely intervention and prevent power loss due to overheating or excessive current.

Step 7: Regular Maintenance Checks

Conduct routine inspections and maintenance checks to identify and address potential issues before they escalate. Cleaning, verifying connections, and ensuring the integrity of the shunt resistor contribute to its long-term reliability and help minimize power loss.

Step 8: Employ Energy-Efficient Components

Consider using energy-efficient components in conjunction with shunt resistors. Select components with low power consumption and high efficiency to reduce the system’s overall energy wastage.

Step 9: Optimize System Design

Evaluate the overall system design to identify opportunities for optimization. This may include re-evaluating the arrangement of components, adjusting current paths, or considering alternative circuit configurations to further minimize power loss in high-current shunt resistor applications.

By following these steps, engineers can systematically address various factors contributing to power loss, ensuring that high-current shunt resistor applications operate efficiently and reliably over the long term. Integrating these strategies into the design and maintenance of electrical systems will improve performance and reduce energy consumption.

Minimizing power loss in high-current shunt resistor applications requires a comprehensive approach encompassing resistor selection, thermal management, and precise current measurement.

Apart from the above strategies, choosing the proper shunt resistors from distributors like WIN SOURCE can significantly minimize power loss in these applications. WIN SOURCE is a reputable electronic components distributor that offers a range of components, including shunt resistors, that meet high-quality standards.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS