The ever-increasing demand for energy efficiency in electrical products has catalyzed the development of more accurate power measurement instruments. These modern tools are crucial for quantifying incremental improvements in efficiency, drawing more work from each kilowatt-hour.

Especially in electrical products such as motors, which already operate at efficiencies above 95%, fine-tuning for greater efficiency is a challenging yet critical goal for manufacturers.

Power analyzers and meters are instrumental in achieving this, offering precision and accuracy for confirming efficiency enhancements.

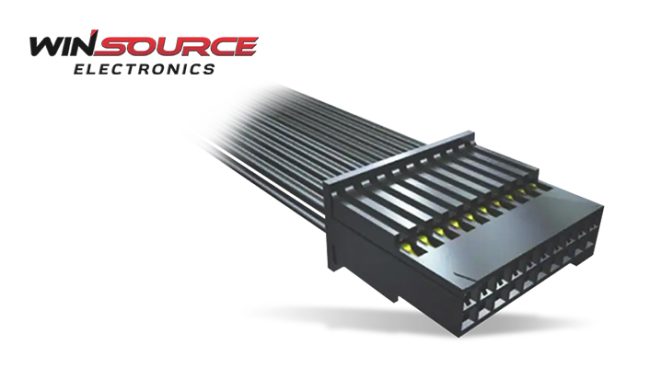

The Role of High Precision Connectors

High-precision connectors like Samtec 28C-F play a vital role in power measurement. Their importance is magnified as technology advances, necessitating more efficient and reliable connectors.

These components serve as the electronic link between devices, ensuring precision and reliability in a wide range of electronic applications.

Notably, the precise coupling of devices to the test object (DUT) is paramount in fields demanding exact measurement technology processes, such as laboratory and metrology sectors.

Innovations in High Precision Connectors

Current trends and innovations in the electrical connector industry define their evolving role. Developments such as miniature connectors for space exploration, fiber optic connectors for high-speed data transfer, smart and self-monitoring connectors, and wireless connectors for enhanced mobility and flexibility are shaping the future of electrical connectors.

Current Measurement Methods in Power Electronics

In power electronics, current measurement is primarily conducted through two methods: direct connection and current sensor.

Direct Connection Method: A Traditional Approach

The direct connection method has been a longstanding technique for measuring current. This method involves routing wires from the object being measured to the power analyzer’s current input terminals.

Despite its simplicity and the ability for standalone measurement, this technique faces notable challenges. First, the actual operating conditions are altered during measurement. Second, resistance-related losses are inevitable due to the long wire distances involved, leading to increased wire resistance and capacitive coupling.

Furthermore, when measuring large currents, even small inductive components introduced by the shunt resistance can significantly affect the frequency characteristics.

Current Sensor Method: Improved Precision for Large Currents

Transitioning to the current sensor method involves connecting a current sensor to the equipment under test, with the sensor’s output signal (current or voltage) fed into the power analyzer.

Its primary advantage lies in its capacity to measure large currents (around 5 A or more) with minimal self-heating, which, in turn, does not affect measurement accuracy. The method is particularly advantageous in power electronics for its high precision in measuring large currents.

However, the current sensor method’s effectiveness depends significantly on the current sensor’s choice. Selection criteria should consider the sensor’s rated current value and the frequency band it can measure.

Additional factors like measurement accuracy across the sensor’s frequency band and various error factors (such as output noise and temperature characteristics) must also be taken into account.

Optimizing Power Measurement Systems

Optimizing the entire power measurement system, not just the current sensor, is crucial for high precision in power measurements using the current sensor method.

It involves ensuring a high-quality power supply for the sensor, minimizing coupling capacitance between cables, and using power analyzers with high insulation performance and noise resistance.

Achieving precision in power measurements necessitates careful and harmonious integration of components from different manufacturers, considering each element’s unique specifications and compatibility.

While current sensors offer real-time monitoring to help prevent circuit overloads and enhance energy efficiency, they also have limitations. For instance, transformers in current sensors cannot measure DC currents, and Hall-effect sensors might be influenced by external magnetic fields.

High Precision Power Measurement: Techniques and Challenges

Accurate Phase Relationships and Harmonic Measurement

Precision in power measurement hinges on the precise assessment of phase relationships and harmonic content. Electric power, essentially energy per second, is derived from the product of voltage and current.

The phase angle between these two parameters is crucial, especially in AC circuits containing capacitance, inductance, or both, where real and reactive power are involved.

A phase difference between current and voltage produces reactive power, which does not perform work but impacts the circuit’s efficiency.

In this context, measuring harmonics, the multiples of the fundamental frequency, becomes critical, particularly when testing to standards requiring specific harmonic orders.

Power, Accurac,y and Measurement Uncertainty

Power accuracy is an essential aspect of power measurement, reflecting the uncertainty inherent in measurement devices.

Accuracy in power measurement devices is often expressed as a range, considering basic parameters like voltage, current, and phase angle. The concept of “guaranteed accuracy” versus “typical accuracy” is pivotal, with the former offering more reliability.

For AC power measurement, the precision at various frequencies, including harmonic frequencies, is significant. Ensuring accuracy in these measurements is paramount, as inaccuracies can lead to substantial errors in power assessment.

The Significance of Resolution in Power Measurement

Resolution in power measurement is critical, as it defines the smallest increment an instrument can detect or display. Higher resolution equates to finer detail detection in waveforms, which is vital for accuracy in power measurements.

However, achieving higher resolution often comes at the cost of sampling speed. Instruments like digital storage oscilloscopes and waveform recording systems vary in their resolution capabilities.

The choice of an instrument with appropriate resolution is crucial, depending on the measurement requirements. In scenarios requiring the highest accuracy, instruments with the greatest resolution, such as power analyzers, are recommended.

The precision of power measurements directly impacts the performance and efficiency of electrical energy conversion, whether for heating, motor torque, or lighting. Ensuring high precision in these measurements is essential for optimizing the functionality and effectiveness of power-related applications.

Search electronic components with ease at WIN SOURCE – your trusted online destination for all electronic components. Visit us now!

COMMENTS