Understanding JST Connectors

JST, or Japan Solderless Terminal, is a renowned name in the world of connectors. These connectors are widely used in various electronic applications, from consumer electronics to industrial machinery. The compact and reliable design of JST connectors makes them a preferred choice for engineers and designers aiming for efficient and durable electronic connections.

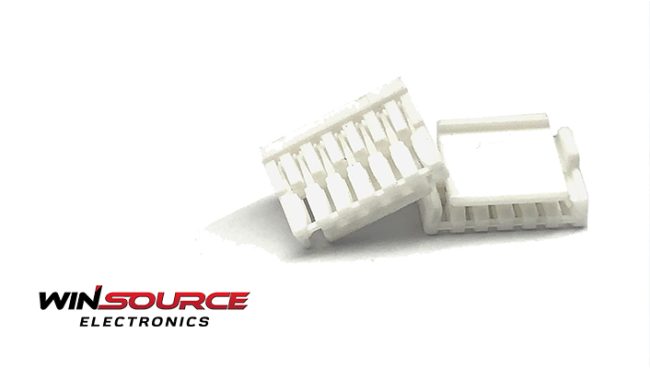

Connector Housing Types

JST connectors come in different shapes and sizes, and their housing types vary to accommodate diverse applications. Two primary categories are rectangular connector housings and circular connector housings.

1. Rectangular Connector Housings:

Rectangular connector housings are the workhorses of electronic design. Their boxy structure allows for efficient packing of multiple contacts in a confined space. The rectangular design is often chosen for applications where space optimization is critical, such as in mobile devices and compact electronic gadgets.

These housings are available in various pitches, referring to the distance between adjacent contacts. Common pitch sizes include 2.0mm, 2.5mm, and 2.54mm. The pitch determines the spacing of the holes in the housing, and the choice depends on the specific requirements of the electronic circuit.

The holes structure in rectangular connector housings is designed with precision. Engineers carefully consider the pitch, the number of holes, and their arrangement to ensure a secure and reliable connection. The housing acts as a protective shell, shielding the delicate metal pins from external elements and potential damage.

2. Circular Connector Housings:

Circular connector housings, on the other hand, deviate from the traditional boxy design. They find applications in scenarios where a more robust and versatile connection is required. Circular connectors are often chosen for industrial applications, aerospace systems, and outdoor equipment due to their durability and resistance to environmental factors.

These housings are designed to accommodate circular arrangements of pins, offering a more flexible and adaptable design. The circular form factor allows for easier installation and removal, making them suitable for applications that require frequent connections and disconnections.

Pitch and Its Implications

Pitch, a fundamental aspect of connector housing design, plays a crucial role in determining the overall performance of the JST connector. It refers to the distance between the centers of two adjacent contact points. The choice of pitch depends on the specific requirements of the electronic circuit and the space constraints of the application.

A smaller pitch results in a higher contact density, enabling the design of compact and space-efficient electronic devices. However, a smaller pitch may also pose challenges during assembly and increase the risk of short circuits if not handled with precision. On the other hand, a larger pitch provides more space between contacts, making assembly easier but potentially increasing the overall size of the connector.

The pitch is a trade-off between space optimization and ease of assembly, and engineers must carefully consider the application’s demands to select the most suitable pitch size for a given JST connector.

Holes Structure and its Significance

The holes structure within the connector housing is a critical aspect that directly influences the connector’s functionality. Engineers meticulously design the arrangement of holes to ensure a secure and reliable connection between the contacts.

The number and pattern of holes in the housing correspond to the arrangement of pins on the connector. The holes must align precisely with the pins to establish a proper electrical connection. Additionally, the structure of the holes contributes to the overall stability of the connection, preventing unintended disconnections or signal disruptions.

In rectangular connector housings, the holes are often organized in a grid pattern, with a specific pitch that matches the spacing of the contacts. This grid pattern allows for efficient packing of contacts in a confined space while maintaining a systematic and organized layout.

In circular connector housings, the holes are arranged in a circular pattern, complementing the circular arrangement of pins. This design facilitates a more robust and secure connection, especially in applications where vibration, shock, or environmental factors may challenge the stability of the connection.

Heat Dissipation Strategies: Managing Thermal Challenges in JST Connector Housings

Thermal Challenges in JST Connector Housings:

While the focus on connector housing design is primarily on electrical performance and structural integrity, it’s crucial to address the thermal challenges that may arise. As electronic devices continue to evolve and pack more functionality into smaller spaces, heat dissipation becomes a critical consideration.

Factors Influencing Heat Generation:

Electronic components within JST connectors can generate heat during operation. Factors such as high current flow, tight packing of contacts, and extended usage can contribute to increased temperatures within the connector housing. Elevated temperatures can adversely affect the performance and reliability of electronic devices.

Heat Dissipation Strategies:

Engineers employ various strategies to manage thermal challenges in JST connector housings:

Material Selection: The choice of materials for connector housings plays a significant role in heat dissipation. Materials with high thermal conductivity, such as certain metals or thermally conductive plastics, can help dissipate heat more effectively.

Enhanced Design for Airflow: Improving the housing design to facilitate better airflow can aid in heat dissipation. This may involve incorporating vents, channels, or specific shapes that promote the natural flow of air around the connectors.

Thermal Management Coatings: Applying thermal management coatings to the connector housing surface can enhance heat dissipation. These coatings are designed to improve the housing’s ability to radiate heat, mitigating temperature build-up.

Increased Surface Area: Enlarging the surface area of the connector housing can enhance heat dissipation. This can be achieved through fins, ridges, or other geometric features that increase the contact area with the surrounding air.

Integrated Heat Sinks: In some cases, integrating heat sinks into the connector housing can provide an effective means of dissipating heat. These heat sinks can be designed to efficiently transfer heat away from critical components.

JST connector housings play a crucial role in electronic design. These components, essential for connecting various electronic devices, ensure secure and reliable connections. Their importance lies in maintaining the integrity of the electrical system and preventing potential malfunctions.

One notable distributor for electronic components, including JST connector housings is WIN SOURCE. They offer a wide range of these components, catering to the diverse needs of electronic designers and manufacturers. WIN SOURCE’s commitment to providing quality products contributes significantly to the overall reliability and performance of electronic devices.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS