Wire-to-board connectors are critical components in electronic systems, facilitating the seamless transmission of signals and power between various elements. Here’s where the SL 3.5/5 series emerges with distinct features. It boasts a contact material of copper and tin plating, underscoring durability and reliability.

Let’s learn more about the mating cycles and durability of SL 3.5/5 connectors, shedding light on their performance under diverse conditions.

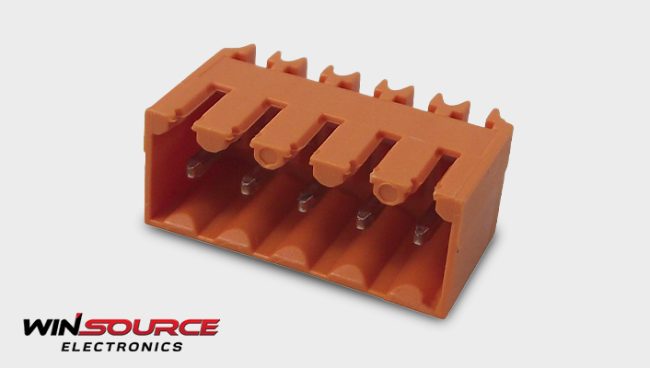

Features of SL 3.5/5/180G Wire-to-Board Connector

The SL 3.5/5/180G Wire-to-Board Connector stands out when it comes to electronic connectors due to its distinctive features, carefully designed to meet the demands of modern electronic applications. Here is an in-depth exploration of its key attributes:

Contact Material: Copper

The connectors boast copper as the contact material, a choice known for its excellent electrical conductivity. Copper ensures efficient signal and power transmission, improving the connector’s overall performance and reliability.

Contact Plating: Tin

Tin plating on the connectors’ contacts provides several advantages, including corrosion resistance and solderability. This feature enhances the connectors’ durability, making them suitable for a wide range of environments and applications.

Material: Steel

Constructed with steel, the SL 3.5/5/180G connectors exhibit robustness and durability. Steel’s strength and resistance to wear and tear contribute to the connectors’ ability to withstand mechanical stress, ensuring longevity in various usage scenarios.

Mount: Through Hole

The connectors are designed with a through-hole mount, facilitating secure and stable attachment to circuit boards. This mounting style enhances the connectors’ mechanical stability, making them suitable for applications where reliability is paramount.

Current Rating: 10 A

With a substantial current rating of 10 A, the SL 3.5/5/180G connectors can handle relatively high levels of electrical current. This feature makes them suitable for applications that demand robust power transmission capabilities.

Gender: Male

The connectors have a male gender, implying that they feature protruding pins that establish connections with corresponding female connectors. This gender specification ensures compatibility and proper alignment in electronic systems.

Number of Contacts: 5

The connectors provide versatility for applications requiring multiple connections, featuring a single row with five contacts. The specific number of contacts caters to various electronic configurations, enhancing the connectors’ adaptability.

Number of Rows: 1

Designed with a single row of contacts, the connectors are streamlined for applications where a compact and straightforward configuration is preferred. This design choice contributes to space efficiency on circuit boards.

Termination: Through Hole

The connectors employ a through-hole termination method, simplifying the soldering process during installation. Through-hole termination enhances the mechanical stability of the connectors on the circuit board, reducing the risk of disconnection.

Voltage Rating (DC): 250 V

With a DC voltage rating of 250 V, these connectors can reliably handle a range of voltage levels. This feature makes them suitable for diverse electronic applications with varying voltage requirements.

Lead Pitch: 3.5 mm

The connectors feature a lead pitch of 3.5 mm, indicating the distance between the centers of adjacent contacts. This pitch size is a critical parameter influencing the connectors’ compatibility with other components, ensuring proper alignment and connection reliability.

A Look at the Methodology

Selection of SL 3.5/5 Connectors:

In the initial phase, connectors from the SL 3.5/5 series were carefully chosen based on specific attributes such as contact material (copper), contact plating (tin), and other critical specifications. The selection process ensures that the connectors used in the study accurately represent the SL 3.5/5 series.

Experimental Setup:

The experimental setup involved designing and implementing a sophisticated testing apparatus to assess mating cycles and durability. A dedicated apparatus was devised to subject the connectors to repeated connection and disconnection cycles for mating cycle testing. Additionally, environmental conditions for durability testing were carefully controlled to replicate real-world scenarios.

Data Collection Methods:

A variety of data collection methods were employed to gather comprehensive insights. The study monitored the mating cycle count to understand how connectors responded to repeated use. Performance metrics, including changes in electrical conductivity and mechanical properties, were meticulously recorded. Failure analysis techniques were also applied to scrutinize any deviations from expected performance.

Mating Cycle Testing

Mating cycles refer to the repetitive process of connecting and disconnecting electronic connectors. Understanding the significance of mating cycles is crucial as they directly impact the operational lifespan and reliability of the connectors. For SL 3.5/5 connectors, the goal was to establish their limits and performance characteristics under various mating conditions.

Procedure:

The mating cycle testing procedure involved initiating a baseline condition, incrementally increasing the mating cycles and closely monitoring changes in electrical and mechanical properties. This systematic approach provided a clear picture of how SL 3.5/5 connectors respond to different stress levels and usage.

Results and Analysis:

The results of the mating cycle tests were analyzed to assess the performance of SL 3.5/5 connectors. This involved evaluating their resilience to repeated mating cycles, understanding any degradation in electrical conductivity, and observing wear and tear patterns. The analysis aimed to provide insights into the connectors’ reliability and suitability for various applications.

Durability Testing

Importance of Durability:

Durability is a critical factor in the functionality and longevity of electronic connectors. For SL 3.5/5 connectors, assessing durability involves subjecting them to a battery of tests under different environmental conditions to simulate the challenges they might face during real-world usage.

Test Conditions and Parameters:

Durability testing encompassed exposing SL 3.5/5 connectors to temperature, humidity, vibration, and shock variations and assessing their corrosion resistance. These conditions aimed to replicate the diverse environments these connectors might encounter, providing valuable insights into their robustness and adaptability.

Results and Analysis:

The durability testing results were meticulously analyzed to understand how SL 3.5/5 connectors fared under different environmental stressors. This included evaluating their performance under temperature fluctuations, resistance to humidity-induced effects, resilience to vibrations and shocks, and corrosion resistance.

The analysis aimed to identify potential weak points and failure modes, contributing to a comprehensive understanding of their durability.

Are There Any Challenges and Limitations Associated?

Common Challenges:

This section discusses challenges inherent to wire-to-board connectors and issues commonly encountered in connector technology, providing context for the challenges specific to SL 3.5/5 connectors.

Specific Challenges of SL 3.5/5 Connectors:

This subsection delves into challenges unique to the SL 3.5/5 series, considering their specific design, material composition, and application scenarios. Addressing these challenges is crucial for optimizing the performance and reliability of SL 3.5/5 connectors.

Limitations and Future Research:

This section recognizes the study’s boundaries and outlines any limitations in the experimental design, data collection methods, or other aspects. It also provides suggestions for future research directions, offering insights into areas that warrant further exploration for a more comprehensive understanding of SL 3.5/5 connectors.

The testing of SL 3.5/5/180G Wire-to-Board Connectors revealed a commendable level of durability and sustained performance over an extended number of mating cycles. The connectors demonstrated reliability and resilience, highlighting their suitability for applications requiring frequent connections and disconnections without compromising functionality.

Notably, these connectors are readily available through distributors such as WIN SOURCE. As a reputable distributor, WIN SOURCE plays a crucial role in providing reliable access to these connectors. Furthermore, they ensure that industries and applications in need of robust wire-to-board connectivity solutions can easily source and integrate these connectors into their systems.

COMMENTS