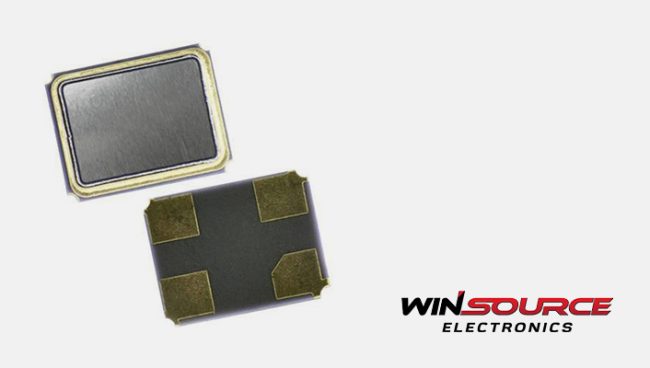

As technology hurdles forward, the demand for compact yet powerful electronic components intensifies. Surface Mount Device (SMD) crystals have emerged as pivotal contributors to this miniaturization revolution, ensuring that devices remain not only smaller but also more efficient.

Amidst the vast landscape of SMD crystals, the ECS ECS-360/20-33-TR emerges as a beacon of innovation. Beyond its fundamental role as a timekeeping element, this crystal possesses overdriving capabilities that elevate it to a league of its own, promising a synergy of precision and adaptability for electronic circuits.

Let’s learn what overdriving capabilities are found in the ECS-360/20-33-TR, so that we can measure the potential for optimizing performance beyond its nominal specifications.

What is Overdriving in Crystal Oscillators?

Overdriving refers to the intentional operation of a crystal oscillator at a higher drive level than its specified nominal value. This technique aims to unlock hidden potential, pushing the crystal to operate beyond its standard limits for enhanced performance.

Overdriving the ECS-360/20-33-TR: Tapping Into Hidden Potential

When it comes to unlocking the latent capabilities of the ECS-360/20-33-TR SMD crystal, delving into specific technical details is essential. Understanding the inherent features of the crystal sets the stage for successful overdriving, allowing engineers to tap into its hidden potential effectively.

Key Considerations for Overdriving

Nominal Frequency Optimization

Overdriving the ECS-360/20-33-TR involves intentional operation at a drive level higher than the specified nominal value. With a nominal frequency of 36MHz, engineers can explore tuning the crystal to operate beyond this standard frequency, potentially unlocking additional performance benefits.

Load Capacitance Adjustment

The load capacitance of 20pF is a critical parameter for stable crystal operation. During overdriving, engineers may need to fine-tune the load capacitance to optimize performance under increased drive levels. This adjustment ensures that the crystal resonates effectively in the new operating conditions.

ESR Management

The Equivalent Series Resistance (ESR) of 40Ω plays a role in the crystal’s impedance characteristics. Overdriving introduces additional stress, and managing ESR becomes crucial for maintaining signal integrity. Engineers should consider how changes in drive levels impact ESR and incorporate strategies to mitigate potential issues.

Frequency Tolerance and Stability under Overdriving

The specified frequency tolerance and stability of ±50 ppm highlight the crystal’s precision. When overdriving, engineers should monitor the crystal’s behavior to ensure that it maintains stability within acceptable limits. This involves careful consideration of the trade-offs between increased drive levels and frequency accuracy.

Temperature Considerations

Operating in a temperature range of -20℃ to +70℃, the crystal’s performance under overdriving conditions may be influenced by temperature fluctuations. Robust circuit design and thermal management are essential to counteract potential variations in the crystal’s characteristics across different temperature scenarios.

By honing in on these specific details, engineers can strategically navigate the intricacies of overdriving the ECS-360/20-33-TR. Tapping into the hidden potential of this SMD crystal involves a nuanced approach that considers nominal frequency, load capacitance, ESR, frequency tolerance, stability, and temperature factors.

Benefits of Overdriving

Enhanced Output Amplitude

Overdriving the ECS-360/20-33-TR can result in an increased output amplitude. This enhancement contributes to improved signal integrity and noise immunity, especially in applications where a robust signal is crucial.

Access to Higher Operating Frequencies

Beyond the standard 36MHz, overdriving may unlock the capability to operate at higher frequencies. This can be advantageous in scenarios where a slight frequency boost is needed for optimal system performance.

Reduced Phase Noise and Improved Timekeeping

In specific applications, overdriving may lead to reduced phase noise and improved timekeeping accuracy. This can be pivotal in precision-critical applications, such as timekeeping modules in communication systems.

Navigating the Trade-offs and Risks

Limitations and Risks of Overdriving

Overdriving increases stress and heat generation within the crystal, potentially shortening its lifespan. Careful consideration of the operational environment is crucial to mitigate this risk.

Higher drive levels can lead to unwanted harmonic and spurious signal generation. Circuit design must account for these potential issues to maintain signal integrity.

Overdriving may compromise temperature stability, making the oscillator more susceptible to environmental factors. Robust circuit design and environmental controls are necessary to counteract these effects.

Importance of Circuit Design Considerations

The success of overdriving the ECS ECS-360/20-33-TR SMD crystal hinges critically on the meticulous design of the circuit and thoughtful component selection. Engineers undertaking this endeavor must delve into the intricacies of several key factors, each playing a pivotal role in ensuring not only enhanced performance but also the longevity of the crystal.

Drive Level Optimization

A fundamental aspect of circuit design for overdriving involves the optimization of the drive level. Engineers need to carefully fine-tune this parameter to strike a delicate balance, ensuring that the crystal operates at a higher drive level without compromising its structural integrity. This optimization process contributes significantly to achieving the desired performance boost without jeopardizing the crystal’s reliability.

Load Capacitance Considerations

Another critical factor in the circuit design equation is the consideration of load capacitance. Engineers must meticulously select the appropriate load capacitance, as specified in the ECS-360/20-33-TR datasheet. This careful selection ensures that the crystal functions optimally under overdriving conditions, preventing issues related to frequency deviations and signal distortions.

Efficient Heat Dissipation Strategies

Overdriving inherently introduces elevated stress levels and increased heat generation within the crystal. To mitigate potential risks associated with excessive heat, engineers must implement efficient heat dissipation strategies in the circuit design. This involves selecting appropriate heat sinks, thermal vias, or other cooling mechanisms to maintain the crystal’s operating temperature within acceptable limits, thereby safeguarding its longevity.

Frequency Stability and Phase Noise Management

Beyond the basic parameters, circuit design considerations must extend to managing frequency stability and minimizing phase noise. Engineers should explore techniques and components that contribute to a stable frequency output under overdriving conditions. This is particularly crucial in applications where precision and accuracy are paramount, such as timekeeping modules in communication systems.

Environmental Adaptability

The operational environment in which the ECS-360/20-33-TR crystal will be deployed is a crucial aspect of circuit design. Engineers must anticipate and address environmental factors that might affect the crystal’s performance under overdriving. Robust circuit design, encapsulation methods, or protective measures can be implemented to enhance the crystal’s adaptability and resilience in diverse conditions.

Characterizing Overdrive Performance with Analytical Techniques

Measurement Methods for Overdriven Crystals

Output Amplitude, Harmonic Content, and Phase Noise Evaluation: Measurements should include assessments of output amplitude, harmonic content, and phase noise across a range of drive levels. Advanced tools like spectrum analyzers and phase noise analyzers are invaluable in obtaining accurate data.

Temperature Stability and Frequency Drift Monitoring

Analyzing temperature stability and frequency drift under overdriving conditions provides insights into the crystal’s behavior in real-world scenarios. This data is crucial for assessing the viability of overdriving in specific applications.

Pushing the Boundaries: Utilizing Overdriven ECS-360/20-33-TR in Real-World Applications

Clocking High-Speed Digital Circuits and Processors: The enhanced signal integrity resulting from overdriving makes the ECS-360/20-33-TR ideal for clocking high-speed digital circuits and processors.

Noise-Critical Environments: Applications demanding superior signal integrity in noise-critical environments, such as communication systems, can benefit from the improved performance achieved through overdriving.

Extended Operating Frequency Range: For specialized applications requiring an extended operating frequency range, overdriving the ECS-360/20-33-TR can be a game-changer.

Design Guidelines for Overdriving

Recommended Drive Level and Load Capacitance Combinations: Carefully select drive levels and load capacitance combinations based on the ECS-360/20-33-TR datasheet recommendations to ensure optimal performance.

Mitigation Strategies for Heat Dissipation and Harmonic Generation: Implement effective strategies for heat dissipation and harmonic generation mitigation to address the associated risks of overdriving.

Suitable Circuit Topologies: Identify circuit topologies suitable for overdriving applications, ensuring compatibility with the ECS-360/20-33-TR’s specifications and performance requirements.

The ECS ECS-360/20-33-TR SMD crystal, with its nominal frequency of 36MHz and remarkable stability, unveils a world of potential through intentional overdriving. While the benefits are enticing, careful consideration of trade-offs, risks, and meticulous circuit design is paramount. By navigating these challenges, engineers can unlock superior performance in real-world applications, pushing the boundaries of SMD crystal capabilities.

Secure your ECS-360/20-33-TR and more through WIN SOURCE, your trusted ally in exploring the frontiers of electronics. The future whispers of breakthroughs. Join the vanguard as we push the boundaries of overdriving techniques in crystals.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS