Sensors and actuators are integral components in electronic and embedded systems. While both contribute to their functionality, they serve distinct purposes. Sensors detect and measure physical quantities, converting them into electrical signals. In contrast, actuators are responsible for initiating physical actions or responses based on electronic signals received. Despite their differences, many people think sensors and actuators are the same, which isn’t true!

So, to help you better understand the difference between sensors and actuators, we will explore their distinct features in detail. Let’s get started!

What are Sensors?

A sensor is an electrical instrument designed to monitor and measure environmental conditions. Upon detecting a change or predefined condition, it transmits electrical signals to the control panel. In sum, sensors identify and measure diverse physical aspects, converting them into electrical signals. Their market is expected to hit around USD 508.64 billion by 2032.

Before proceeding to the distinctions of sensors vs actuators, let’s explore the different types of sensors.

Pressure Sensor

Pressure sensors measure and detect changes in pressure levels. They convert physical pressure variations into electrical signals, and their applications include industrial processes, automotive systems, medical devices, and environmental monitoring. Piezoelectric, capacitive, and resistive sensors are some types of pressure sensors.

SSCMRNN050KGAA5

The TruStability® SSC SSCMRNN050KGAA5 pressure sensor is a cutting-edge solution tailored for board mount applications. It handles pressures up to 7.25PSI (50kPa) with precision. It maintains precision with an impressive accuracy of ±0.25% and operates effectively from -40°C to 85°C. The male 0.08″ (1.93mm) tube, featuring a barbed port style, enhances its adaptability.

Temperature Sensors

As the name implies, temperature detectors work by detecting temperature changes. They are helpful in various things like cars, computers, and air conditioners. There are different types, like thermistors and resistance temperature detectors.

NTC0805J150R

The TE Connectivity Passive Product NTC0805J150R is a temperature sensor NTC thermistor from the Neohm series. It exhibits a resistance of 150 ohms at 25°C, with a tight tolerance of ±5%. Its precision and reliability make it suitable for various temperature-sensing tasks. This sensor’s maximum power rating is 125 mW, and it offers a robust solution for accurate temperature measurements.

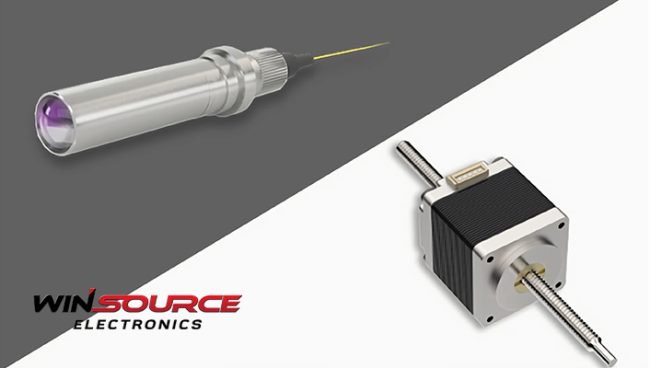

Proximity Sensor

Proximity sensors notice the presence or absence of an object within a specific range without relying on physical contact. Smartphones and elevators are some examples of devices employing proximity sensors.

XSAV11373

The XSAV11373 stands out as a reliable inductive proximity sensor. It has a precise sensing distance of 0.394 inches and operates on a 3-wire PNP-NC output type with cable leads for termination. The unshielded design, coupled with the LED indicator, enhances its functionality. It also works at a temperature range of -25 °C to 70°C, offering versatility in various industrial settings.

What are Actuators?

Actuators easily convert any type of energy, such as electrical energy, into mechanical work. Their work is simple: They take input from the system and give the output to the environment. Fans or heaters are some common examples of actuators.

Let’s look at the types of actuators, and then we’ll discuss sensors Vs actuators in detail!

Manual Actuators

A manual actuator – lever, wheels, etc – is operated by hand to control or manipulate a mechanism or system, providing a direct and human-controlled input.

Electric Actuators

Electric actuators change electrical energy into mechanical motion or force. They use electric power to drive and control various mechanisms, enabling precise and automated movement in applications such as robotics, industrial machinery, and automation systems.

Spring Actuators

Spring actuators use the power of a spring to generate mechanical motion or perform a specific action within a system or mechanism. In short, they use potential energy stored in a compressed spring to create movement or force when released or triggered.

A Detailed Comparison: Sensors vs Actuators

Here’s an overview of the sensors vs actuators difference:

Definition

Sensors function as detectors, discerning alterations or occurrences in the surrounding environment and transmitting the gathered data to other electronic components or devices. Conversely, actuators operate as integral machine components, orchestrating the movement and control of diverse mechanisms within a system.

Functionality

In terms of functionality, sensors primarily measure physical quantities, providing input from the surrounding environment. Actuators, in contrast, measure discrete and continuous process parameters, receiving input from the system’s output conditioning unit to initiate specific actions.

Electrical Signals

Sensors generate electrical signals to respond to environmental conditions, converting the detected changes into electronic data. Actuators, conversely, utilize electrical signals to produce physical actions, translating electronic input into mechanical or thermal output.

Placement

The placement of these components within a system varies. Sensors are positioned at the input port, receiving input from the environment. At the same time, actuators are strategically located at the output port to influence the system’s mechanical or thermal output.

Inputs and Outputs

Sensors scrutinize environmental inputs, responding to changes by triggering specific actions within the system. Actuators, however, focus on tracking the outputs of systems and machines, ensuring the desired actions are executed.

Applications of Sensors vs Actuators

Here are some applications of sensors Vs actuators:

Actuators

Robotics: Drive movement in robots for tasks like grasping objects and precise positioning.

Automotive Systems: Control engines, brakes, and steering systems, influencing acceleration and direction.

Aerospace: Govern control surfaces, landing gear, and propulsion systems in aircraft and spacecraft.

Industrial Machinery: Control valves, pumps, and mechanical components in manufacturing processes.

Sensors

Environmental Monitoring: Measure temperature, humidity, and air quality for weather forecasts and pollution control.

Healthcare Monitoring: Track vital signs and patient movements for real-time medical data.

Automotive Systems: Assist in collision detection, parking, tire pressure monitoring, and engine optimization.

Sensors and actuators play crucial roles in embedded and electronic systems. Sensors help detect environmental changes, while actuators generate mechanical action. If you are searching for the best sensors or activators, consider WIN SOURCE your ultimate stop. We serve as a B2B intermediary, connecting businesses with electronic component manufacturers to streamline import processes.

Businesses can benefit from a seamless and hassle-free importation experience through our efficient collaboration with top-notch manufacturers. Contact us today to explore how our services encompass efficient procurement and logistics for electronic components, ensuring a smoother journey for your imports.

© 2024 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS