The traditional way of connecting two wires is to remove the insulation and join them by twisting. But is this the safe way? What if you need to join multiple or many wires together to a single wire? It needs some alternative and safer options. That’s where terminal blocks come in.

Let’s explore what a terminal block is, its benefits, types, and other important considerations while using it.

What are Terminal Blocks?

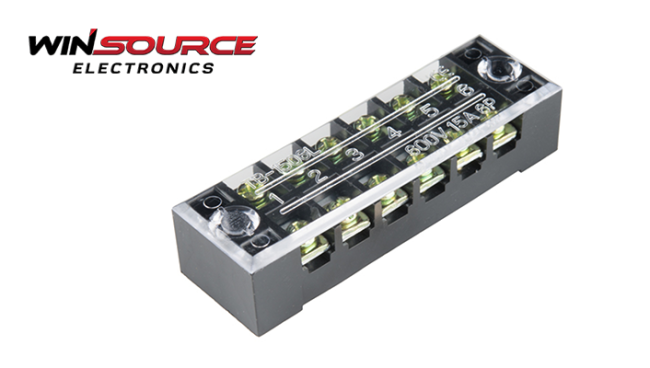

Terminal blocks, also known as connection terminals or terminal connectors, are modular blocks connected with an insulated frame consisting of a clamping component and a conducting strip.

The insulating body of a terminal block uses a current-carrying element and offers a base for the clamping part. The body also has a special arrangement to easily mount or unmount from a PCB or mounting rail. These days, most of the terminal blocks are usually modular and mounted on DIN rail.

You can increase the number of terminals according to the requirements. These electrical terminal blocks are the best way of keeping wire connections safe and arranged.

Benefits of Terminal Blocks

Here are a few key benefits of terminal blocks;

Saving Space

The most prominent benefit of using blocks is saving space. When wires are joined together with the help of the terminal block connectors, it becomes easier to access and adjust them, freeing up a lot of space.

Easy Maintenance

Arranged wires via terminal connectors make troubleshooting the faults and detecting issues easier. It significantly enhances productivity and reduces downtime.

Minimise Errors

Another benefit of using terminal blocks is that they provide a quick way to join wires, reducing the chances of wrong installation and saving time and effort.

Safety

These reduce the risks of electrical shocks by exposed wires and short circuits. Lesser chances of faulty wiring also help avoid electrical hazards.

Types of Terminal Blocks

These can be categorised based on their structure, the device type they connect with, or termination options.

Let’s briefly discuss this classification to solidify your understanding of these connectors:

Structure-based Classification

Single level:

This type of terminal block, also called a single-feed terminal, connects two distinct wires. This is the simplest type of terminal connector.

Dual level:

This terminal block type has two contact layers, offering simplified wiring. Some products may use bridges to connect both layers for enhanced circuit functioning.

Three level:

Similar to dual-level, this type has additional layers of contacts that offer comprehensive wiring. These contact layers can also be connected via bridging.

Device-based Classification

Fuse blocks:

As obvious from the name, these types of terminal blocks connect fuses from various devices together.

Ground circuit blocks:

These are used for grounding components and systems. They can replace standard terminal connectors and be inserted into a block for flexible wiring.

Thermocouple blocks:

These types of blocks connect thermocouples for constantly measuring temperature.

I/O blocks:

These terminal blocks connect the system and controllers.

Sensor blocks:

This type of connector connects three- and four-wire devices such as photoelectric sensors for smooth current flow.

Termination-based Classification

Screw-in blocks:

They are the most commonly used terminal connectors. Using screws to hold wires, these blocks need care in handling as over-tightening might cause wiring issues.

Barrier block:

Barrier terminal blocks, or Europe connectors, work the same as screw-in terminal blocks. They take the help of screws to clamp the wires.

Pluggable blocks:

These consist of a plug that permits connection to a socket. The wire is inserted with a clamp having a screw. You can make connections to the wire with the help of plug and socket configuration.

So, these types of terminal blocks are used when a quick disconnect is needed.

Push-in terminal blocks:

Push-in and push-fit terminal blocks are getting famous day by day, and just like spring-loaded terminal blocks, the push-fit needs wire that a ferrule must cover. The main difference between push-in and spring-loaded blocks is the method of releasing wire.

On the other hand, push-fit terminal blocks have the release device mounted close to the wire insertion point.

Terminal Block Specifications and Electrical Considerations

Knowing the essential terminal block specifications like orientation, mounting, termination type, and contact options can help you create a practical circuit resilient to dangerous electrical incidents.

- Orientation: You will find terminal connectors in three main types: vertical, horizontal, and 45 degrees. Vertical and horizontal types are also known as 180-degree- and 90-degree types.

- Contact type: Terminal contact, or position or pole, indicates the wire attached to the block. Depending on the number of cables attached, a typical block can accommodate from single to 24 circuits or more.

- Wire size and type: Terminal blocks accommodate wire ranging from 184 to 2412 AWG, where AWG (American Wire Gauge) is used in North America. You should know the wire size that will fit the block and its type.

- Rating: The current rating is essential when deciding to use connectors. It is recommended to use connectors capable of bearing 150% of the current expected to flow within the system.

- Pole count: The number of circuits within a terminal block is known as pole count; it ranges from single to 24 or beyond, depending on the application requirements.

- Mounting: Blocks are typically mounted on rails, PCB (Printed Circuit Board) or screwed onto panels.

- Termination type: Block connectors use several termination methods like spring or screw clamps, IDC (Insulation displacement connections), or tab connections to connect wires.

How to Select the Correct Terminal Block for Your Application?

Always consider factors such as current and voltage requirements, wire type, and termination method to ensure the best selection for the application. Do not neglect safety considerations while choosing a terminal block. Always select a terminal block with a current rating higher than needed to prevent overheating and damage while paying attention to insulation performance.

Terminal blocks are the components that are connected with an insulated frame, and their primary purpose is to secure wires together. They save space and provide enhanced safety and easy equipment maintenance. They are categorised by structure, device type, and termination options. Always ensure to buy high-quality products from reliable vendors to build customer trust.

If you’re looking to buy terminal blocks or their accessories, WIN SOURCE is here to help you resource them from reputed manufacturers at the most affordable prices.

We are constantly expanding our network of suppliers who can even provide you with obsolete or hand-to-find parts. We ensure reduced procurement cycles, lower transaction fees, and authentic electrical components according to your needs.

Feel free to explore our wide range of electrical components, including blocks of all types.

COMMENTS