What is GSMR?

GSMR stands for Gray Scale Magnetic Rotary Encoder. It is a type of rotary encoder that uses magnetic sensors to detect changes in magnetic fields caused by rotating permanent magnets on a shaft. Unlike other types of rotary encoders, which use mechanical or optical sensing methods, GSMR encoders are non-contact and therefore have a longer lifespan and higher accuracy.

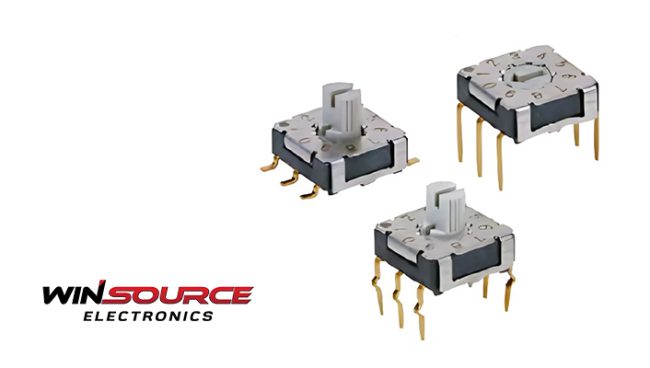

How does a GSMR-10S Rotary Encoder Work?

The GSMR-10S rotary encoder is an incremental encoder, meaning it produces a series of digital pulses based on the rotational movement of its shaft. These pulses can be used to determine both the direction and speed of rotation. The key to the high accuracy and precision of a GSMR-10S encoder lies in its magnetic sensors and permanent magnets.

The encoder disc or wheel contains several alternating north and south pole permanent magnets, while the sensor head contains multiple magnetic sensors arranged in a circular pattern. As the shaft rotates, the magnets on the disc pass by the sensors, causing changes in the magnetic fields detected by the sensors.

This change is then translated into digital pulses which are sent to a decoder, allowing for precise measurement of angular position and movement.

Features and Advantages of GSMR-10S Rotary Encoders

One of the main features of GSMR-10S rotary encoders is their high resolution. The disc can be designed with a high number of magnets, providing a large number of pulses per revolution. This allows for very precise measurements, making GSMR encoders ideal for use in applications where accuracy is crucial.

Additionally, GSMR-10S rotary encoders have a wide operating temperature range and are resistant to dust, dirt, and vibration. This makes them suitable for use in harsh environments such as industrial machinery, where other types of encoders may not be able to withstand the conditions.

Moreover, GSMR-10S encoders have a long lifespan due to their non-contact sensing method. Unlike mechanical or optical encoders, which require physical contact between the sensor and shaft, GSMR encoders do not experience wear and tear over time. This significantly reduces maintenance and replacement costs.

Another advantage of GSMR-10S encoders is their compact size and easy installation. They have a low profile and can be easily mounted on any rotating shaft without taking up much space. This makes them suitable for use in small electronic devices where space is limited.

Applications of GSMR-10S Rotary Encoders

1. Industrial Automation

GSMR-10S rotary encoders are widely used in industrial automation systems for precise control of machinery and equipment. These encoders can accurately measure the speed and direction of rotation, making them ideal for use in conveyor belts, motorized rollers, and other automated systems.

2. Robotics

The high accuracy and compact size of GSMR-10S encoders make them popular in robotics applications. They are used to precisely measure the movement and orientation of robotic arms and joints, allowing for precise and coordinated movements.

3. Medical Equipment

GSMR-10S rotary encoders are also found in medical equipment such as surgical robots and diagnostic machines. The high resolution and accuracy of these encoders are critical for precise and safe operation in medical settings.

4. Automotive Industry

In the automotive industry, GSMR-10S encoders are used in various parts of a vehicle, including steering systems, transmission systems, and engines. The high accuracy and durability of these encoders make them suitable for use in harsh conditions such as extreme temperatures and vibrations.

5. Aerospace and Defense

GSMR-10S encoders are also used in the aerospace and defense industry for flight control systems, navigation equipment, and weapon systems. In these applications, accuracy and reliability are crucial for safe and effective operation.

6. Consumer Electronics

With the rise of smart devices and gadgets, GSMR-10S rotary encoders are increasingly being used in consumer electronics such as gaming controllers, cameras, and virtual reality devices. Their compact size and high resolution make them ideal for precise control in these devices.

7. Renewable Energy

GSMR-10S encoders play an important role in renewable energy systems such as wind turbines and solar panels. They are used to accurately measure the position of blades or panels, allowing for optimal positioning and efficiency.

8. 3D Printing

In the field of 3D printing, GSMR-10S encoders are used in the movement and positioning of print heads and build platforms. Their high accuracy and resolution ensure precise and consistent printing.

GSMR-10S rotary encoders are an advanced and versatile type of encoder with many features and advantages. Their applications in various industries and devices showcase their importance in modern technology. To explore and purchase GSMR-10S encoders, visit WIN SOURCE, a trusted distributor of electronic components with a wide range of quality products.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS