In modern electronic manufacturing, color detection of components has become a critical part of quality control. Whether in consumer electronics, industrial equipment, or medical devices, ensuring the consistency of appearance and functionality of electronic components directly affects product reliability and customer satisfaction. Broadcom’s ADJD-E622-QR999 RGB color sensor exemplifies advanced technology, offering high performance and flexibility for these applications.

Understanding the Need for Color Detection in Electronic Components

Electronic components often require color differentiation to identify models, specifications, or functions. For instance, resistors and capacitors may use color codes to represent values, while LED displays need precise color rendering to meet design requirements. Errors in color can lead to assembly mistakes, functionality issues, or even product failure. Additionally, in high-density PCB assembly, color markings aid in quickly identifying component positions and polarity, reducing the risk of production errors. Therefore, high-precision color detection equipment is essential for monitoring component quality.

The Role of ADJD-E622-QR999 in Component Detection

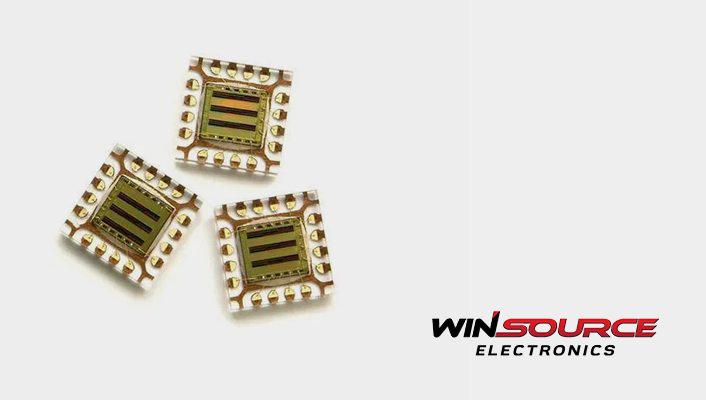

The ADJD-E622-QR999 RGB color sensor is widely used in electronic component detection due to its superior technical performance. It integrates an RGB sensing module, built-in white LED illumination, and a high-precision optical lens, meeting diverse color detection needs.

- Accurate Color Detection: Detects subtle color differences, ideal for parameter marking or color coding in components.

- Stable Built-in Illumination: A white LED ensures uniform lighting, reducing interference from ambient light.

- Compact Modular Design: Its small size facilitates easy integration into production lines.

- Real-time Feedback: The sensor continuously monitors color data, providing rapid feedback to control systems for immediate adjustments.

Applications and Use Cases

The versatility of the ADJD-E622-QR999 makes it an ideal choice in the electronics industry:

- Component Sorting and Identification: Quickly detects color codes on resistors, capacitors, and other components to ensure correct sorting and assembly.

- Color Verification in PCB Assembly: Ensures that soldered LED indicators and other color-coded parts meet design specifications.

- Display and Backlight Testing: Examines color output of LEDs and LCDs to guarantee consistent visual performance.

- Automated Sorting Systems: In warehousing and logistics, the sensor aids in sorting electronic components by color, enhancing efficiency and reducing errors.

Enhancing Manufacturing Efficiency and Quality

Integrating the ADJD-E622-QR999 allows manufacturers to automate color detection processes, significantly reducing human error. Its real-time feedback capability enables swift production adjustments, minimizing defective products. This sensor not only boosts production efficiency but also reduces material waste and rework costs.

Additionally, its precise detection ability helps quality management teams identify potential issues early. For example, by inspecting color consistency, process deviations can be detected in advance, preventing large-scale failures and enhancing overall product quality.

Challenges and Future Developments

Despite its outstanding performance, the ADJD-E622-QR999 may face challenges such as environmental factors, including temperature changes or dust. Regular calibration and protective designs are essential to maintain stability.

In the future, sensor technology is expected to improve with AI algorithms and advanced calibration mechanisms. Machine learning could automatically analyze color deviations in production lines and optimize detection parameters in real-time. Furthermore, trends toward miniaturization and integration will open new possibilities for color detection in complex production environments.

Color detection is not just a step in quality control; it is critical to maintaining production efficiency and product consistency in electronic manufacturing. The ADJD-E622-QR999 RGB color sensor demonstrates exceptional value in this field. From component sorting to display calibration, it has become a vital tool for achieving efficient, accurate, and stable production. As technology continues to evolve, advanced sensors like this will play a significant role in more detection scenarios, supporting high-quality industry development.

Notably, distributors like WIN SOURCE provide not only high-quality electronic components but also comprehensive solution support. By collaborating with leading distributors, manufacturers can efficiently access the resources they need, optimizing supply chain management and quality control, further enhancing their competitive edge.

COMMENTS