Proximity switches play a pivotal role in industrial automation, enabling precise control and monitoring of machinery. Among these, the 240/30 proximity switch stands out for its reliability and versatility.

In this article, WIN SOURCE electronics experts will delve into the key aspects of the 240/30 proximity switch, exploring its functionality, applications, and benefits.

Let’s get the takeaway first.

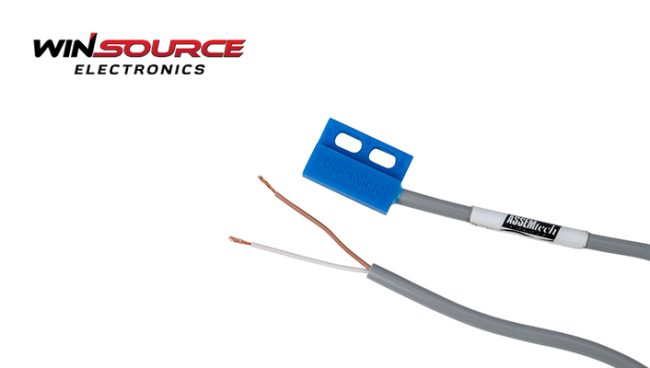

A 240/30 proximity switch is an industrial sensor designed for object detection. Operating on principles like inductive or capacitive sensing, it ensures reliable automation by detecting the presence or absence of objects within its specified range, contributing to precise and efficient industrial processes.

With the mini answer in place, let’s start by discovering more about this powerful electronic device.

Functionality

The 240/30 proximity switch operates on the principle of detecting the presence or absence of an object within its sensing range.

This type of switch uses various technologies, such as inductive, capacitive, or photoelectric sensing, depending on the specific requirements of the application.

The “240/30” designation may refer to specific technical parameters, such as voltage ratings, current ratings, or size specifications.

Applications

One of the primary applications of the 240/30 proximity switch is in industrial automation.

These switches are commonly used to detect the position of objects on conveyor belts, triggering specific actions such as sorting, diverting, or stopping the conveyor.

In manufacturing processes, they contribute to precision and efficiency by ensuring that machinery operates with optimal timing and coordination.

The 240/30 proximity switch also finds utility in automotive assembly lines, where it can be employed for quality control by verifying the presence of components at various stages of production.

Additionally, these switches are utilized in robotics, elevators, and packaging systems, showcasing their adaptability across diverse industrial settings.

Benefits

So, what are the benefits of this innovative technology?

- Reliability: The 240/30 proximity switch is known for its robust design, providing reliable operation even in challenging environments. This durability makes it suitable for applications where consistent and accurate sensing is critical.

- Versatility: With multiple sensing technologies available, the 240/30 proximity switch can be tailored to meet the specific needs of different applications. This adaptability enhances its versatility across various industries.

- Precision: The switch’s ability to precisely detect the presence or absence of objects ensures accurate control in automation processes. This precision contributes to improved efficiency and reduced downtime.

- Ease of Integration: Manufacturers appreciate the ease with which the 240/30 proximity switch can be integrated into existing systems. This simplifies the upgrade of machinery or the implementation of new automation solutions.

Advanced Features

Beyond its fundamental object detection capabilities, the 240/30 proximity switch may include advanced features that enhance its functionality.

Some models come equipped with adjustable sensing ranges, allowing for flexibility in accommodating different object sizes or materials.

Advanced versions also might offer programmable outputs, enabling users to customize responses based on specific detection scenarios.

These features contribute to the 240/30 proximity switch’s adaptability, making it a valuable asset for industrial settings with diverse sensing requirements.

Head over to our store to find high-quality 240/30 proximity switches for all your home and business engineering projects.

Installation and Maintenance

Installing and maintaining the 240/30 proximity switch is typically straightforward, adding to its appeal for industrial applications.

Many models are designed for easy mounting and alignment, reducing setup time.

Regular maintenance is often minimal, with robust construction ensuring longevity.

Periodic checks and cleaning procedures, depending on the operating environment, can help ensure optimal performance over extended periods, contributing to the overall cost-effectiveness of these devices.

Integration with PLCs and Control Systems

The 240/30 proximity switch seamlessly integrates with programmable logic controllers (PLCs) and other control systems commonly used in industrial automation.

This integration allows for centralized monitoring and control, facilitating a more streamlined and efficient operational workflow.

The switch can communicate real-time data to the control system, enabling quick decision-making and response to changes in the production environment.

Industry Standards and Compliance

To meet industry standards and ensure compatibility with different systems, the 240/30 proximity switch undergoes rigorous testing and certification processes.

Compliance with standards such as IP (Ingress Protection) ratings for environmental resistance ensures that these switches can withstand conditions like dust, moisture, and temperature variations.

Adherence to safety standards is crucial, particularly in industries where precision and reliability are paramount.

Future Trends and Developments

As technology continues to advance, the 240/30 proximity switch is likely to witness further improvements and innovations.

Trends such as the integration of smart sensor technologies, connectivity through the Industrial Internet of Things (IIoT), and enhanced diagnostics capabilities could shape the future of proximity switches.

Manufacturers may focus on making these devices even more intelligent, energy-efficient, and capable of supporting the evolving needs of modern industrial automation.

Understanding the 240/30 Proximity Switch – To End With…

So, as we’ve discovered, the 240/30 proximity switch stands as a reliable, versatile, and integral component in the world of industrial automation.

Its advanced features, ease of integration, and compliance with industry standards position it as a cornerstone technology, contributing to the efficiency, safety, and adaptability of automated processes across various sectors.

As industries continue to evolve, the 240/30 proximity switch will likely remain at the forefront of technological advancements, playing a pivotal role in shaping the future of industrial automation.

© 2024 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS