The 4750-5 Screw Jack Flat is a fundamental component in mechanical engineering, specifically within the realm of load-bearing and height-adjustment mechanisms. This particular screw jack type, identified as 4750-5, represents a standardized classification in the domain of mechanical hardware.

Function and Design of 4750/5 Screw Jack Flat

Primarily, a screw jack operates on the principle of a screw thread converting rotational motion into linear motion. The 4750-5 variant likely denotes specific attributes such as load-bearing capacity, thread pitch, or design features like a flat base.

Load-Bearing Capabilities:

The designation ‘4750-5’ might indicate the load-bearing capacity of the screw jack. Load-bearing capacity is a crucial aspect, defining the maximum weight or force the screw jack can support without failing.

Thread Specifications

The numerical aspect, ‘5,’ could signify the thread pitch or diameter of the screw jack. The pitch determines the linear travel achieved per revolution of the screw, while the diameter defines the robustness and stability of the mechanism.

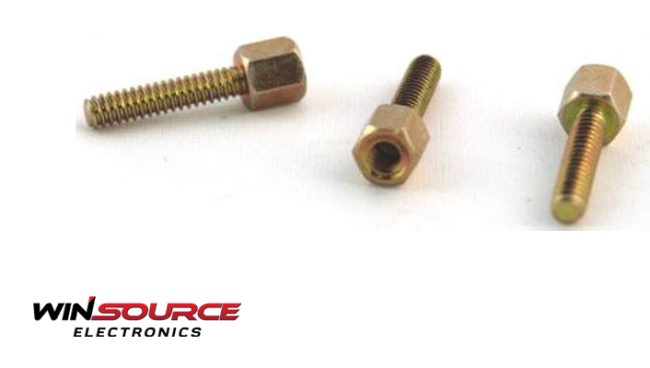

Flat Design

The descriptor ‘Flat’ in the designation may refer to the base or top surface of the screw jack. A flat surface is often essential for stability, enabling the jack to securely support loads without slippage or instability in different components.

Applications of 4750/5 Screw Jack Flat

Screw jacks, including the 4750-5 type, find application in various industries. They are commonly employed in automotive, industrial, construction, and manufacturing settings for tasks involving lifting, lowering, adjusting, or stabilizing heavy loads or equipment. For instance, they might be used in stage platforms, lifting tables, or machinery for height adjustments and load support.

Material and Construction:

Materials used in manufacturing screw jacks are typically durable and corrosion-resistant, such as steel or stainless steel. The construction ensures precision in thread cutting, surface finish, and overall robustness to endure substantial loads and frequent use.

Operational Mechanism:

The operational mechanism involves rotating the screw using a manual crank or a motorized system. As the screw rotates, it raises or lowers the load, providing a stable and controlled lifting or lowering action.

Safety Considerations:

Ensuring proper maintenance and adherence to weight limits is crucial to prevent overload or malfunction. Lubrication and periodic inspections maintain the efficiency and longevity of screw jacks.

How to use 4750/5 Screw Jack Flat?

The 4750-5 Screw Jack Flat represents a specific type of screw jack characterized by load-bearing capacity, thread specifications, a flat design, and applications across diverse industries. It serves as a fundamental component for lifting, adjusting, and supporting heavy loads, offering stability, precision, and reliability in various mechanical systems and applications.

Using a screw jack, like the 4750-5 Screw Jack Flat, involves understanding its capabilities, proper handling, and safety considerations for efficient and safe operation.

Preparation:

Assessment: Determine the load requirements and the desired height or position adjustment needed.

Environment: Ensure a stable, level surface to support the screw jack and the load it will bear.

Safety: Wear appropriate personal protective equipment, especially when dealing with heavy loads.

Steps for Using a Screw Jack:

Positioning:

- Place the screw jack on a stable surface, ensuring the flat base has secure contact.

- Align the screw jack’s base directly under the load’s center of gravity for stability.

Engaging the Screw:

- Use the provided crank or motorized mechanism to engage the screw.

- Insert the crank into the screw’s drive mechanism securely.

Turning the Crank:

- Rotate the crank in the designated direction to either raise or lower the load.

- Gradually turn the crank, ensuring smooth and controlled movement of the screw.

Monitoring:

- Continuously monitor the load as it adjusts. Avoid exceeding the jack’s specified load capacity.

- Check for any signs of instability or strain during the lifting or lowering process.

Adjustment:

- Use the screw jack’s thread pitch and rotation to precisely adjust the height or position of the load.

- Make gradual adjustments, pausing periodically to ensure stability.

Securing the Load:

- Once the desired height or position is achieved, ensure the load is stable and secure.

- Use additional support or locking mechanisms if necessary to prevent accidental movement.

Maintenance and Safety:

- Regularly inspect the screw jack for wear, damage, or signs of malfunction.

- Lubricate the screw and moving parts as recommended by the manufacturer to maintain smooth operation.

Safety Considerations:

- Always adhere to the specified load-bearing capacity to prevent overloading, which could lead to equipment failure or accidents.

- Avoid sudden or jerky movements when adjusting the load to maintain stability.

- Keep hands and other body parts away from moving parts to prevent injuries during operation.

- When not in use, store the screw jack in a safe and dry place to prevent corrosion or damage.

Using a screw jack involves a methodical approach, focusing on safety, gradual adjustments, and proper handling. Understanding the capabilities and limitations of the screw jack, along with regular maintenance, ensures efficient and safe operation, allowing for precise height or position adjustments of heavy loads across various industrial and mechanical applications.

With over a million components in stock, WIN SOURCE offers a comprehensive range, from common parts to rare or obsolete components, making them a one-stop-shop for all your electronic needs. Their components come with a 3-year warranty, ensuring peace of mind and confidence in the quality of their products. WIN SOURCE is dedicated to assisting customers swiftly and accurately in finding components, offering a user-friendly platform, best-in-class search features, and ample product information. Their commitment to fast sourcing and delivery ensures that your components arrive promptly, meeting your project timelines effectively.

© 2024 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS