Basics of Terminal Blocks

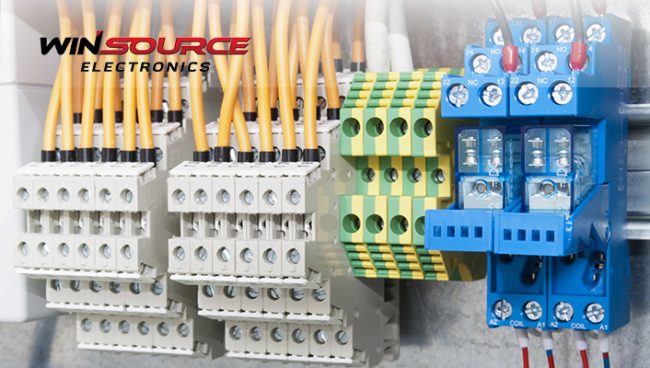

Terminal blocks come in various types, the most common being barrier type, mount type, and DIP (Dual In-line Package). They are typically made from insulating materials, and their conductor materials can be copper or aluminum, depending on the specific application requirements.

Barrier Type Terminal Blocks:

These are commonly used in applications where it’s crucial to maintain separation between different conductors, enhancing safety and reducing the risk of short circuits.

Mount Type Terminal Blocks:

These are designed for easy installation on mounting surfaces and offer flexibility in positioning components within a circuit.

DIP Terminal Blocks:

Dual In-line Package terminal blocks are often used in applications requiring high-density connections, such as PCBs (Printed Circuit Boards).

Advantages of Using Terminal Blocks

Terminal blocks offer a plethora of advantages, making them an indispensable component in the field of electrical engineering.

- Modular Design and Flexibility: Terminal blocks are modular in nature, allowing for easy expansion or modification of circuits. They can accommodate various wire sizes and configurations.

- Easy Installation and Maintenance: Their design simplifies installation and maintenance processes. Wires can be quickly connected or disconnected, making it a straightforward task to add or replace components within a circuit.

- Enhanced Safety Features: Barrier-type terminal blocks, for instance, provide enhanced safety by creating a physical barrier between conductors, reducing the risk of accidental contact or short circuits.

- Improved Electrical Connections: Terminal blocks significantly enhance electrical connections by providing secure, stable connections that minimize the chances of signal interference or power loss.

- Cost-Effectiveness: The durability and longevity of terminal blocks reduce the need for frequent replacements, contributing to long-term cost savings.

Wiring Simplification with Terminal Blocks

Terminal blocks simplify the wiring process, reducing the complexity of electrical connections. They offer several features that streamline the installation and maintenance of electrical circuits:

Reduction in Wiring Complexity: Terminal blocks simplify the interconnection of multiple wires and components, reducing the complexity of wiring diagrams.

Clear Marking and Labeling: Terminal blocks are typically well-marked and labeled, making it easy to identify and troubleshoot connections.

Reduction of Wiring Errors: The clear organization and separation of conductors minimize the risk of wiring errors, enhancing system reliability.

Streamlined Troubleshooting and Maintenance: In case of malfunctions, terminal blocks make it easy to identify and rectify issues, reducing downtime and improving overall system reliability.

How Terminal Blocks Improve Electrical Connections

Terminal blocks are essential components in electrical systems, and they play a crucial role in enhancing the quality and reliability of electrical connections. Here, we delve deeper into the specific ways in which terminal blocks contribute to improved electrical connections, providing secure and efficient pathways for the flow of current and data.

Secure and Reliable Connections

One of the primary functions of terminal blocks is to establish secure and reliable electrical connections. They achieve this through various mechanisms:

Tightening Mechanisms: Screw-type terminal blocks, for example, utilize screws to clamp down on the conductor, creating a tight connection. The torque applied during installation ensures that the conductor remains firmly in place, reducing the risk of loose connections or disconnections due to vibrations or environmental factors.

Spring-Clamp Technology: Spring-clamp terminal blocks use a spring-loaded mechanism to grip the conductor securely. When the conductor is inserted, the spring mechanism exerts a constant force, maintaining a consistent connection and compensating for conductor expansion and contraction due to temperature changes.

Vibration Resistance

In applications where mechanical vibrations are prevalent, such as in industrial machinery or automotive systems, maintaining stable electrical connections is critical. Terminal blocks are designed with features that enhance vibration resistance:

Spring-Clamp Mechanism: Spring-clamp terminal blocks, with their constant pressure on the conductor, are particularly effective in preventing disconnections caused by vibrations. The spring mechanism absorbs shocks and vibrations, ensuring a secure connection.

Locking Mechanisms: Some terminal blocks include locking features that keep wires securely in place, even in high-vibration environments. These locks prevent accidental wire dislodgement.

Corrosion Resistance

In outdoor or harsh industrial environments, exposure to moisture and corrosive agents can compromise electrical connections. Terminal blocks are often constructed to resist corrosion:

Materials Selection: Terminal blocks are made from materials known for their resistance to corrosion, such as stainless steel, nickel-plated brass, or corrosion-resistant plastics. This choice of materials ensures the long-term durability of the terminal blocks.

Environmental Sealing: In some applications, terminal blocks are equipped with environmental seals or gaskets that protect against moisture and contaminants, further enhancing their corrosion resistance.

High Current and Voltage Handling

Different applications require terminal blocks to handle varying levels of current and voltage. Terminal blocks are designed to accommodate these diverse requirements:

Current Ratings: Terminal blocks come in a wide range of current ratings, from low-amperage blocks suitable for control circuits to high-amperage blocks used in power distribution. This adaptability ensures that the terminal block can safely handle the current passing through it.

Voltage Ratings: Voltage ratings of terminal blocks are also varied, allowing them to be used in low-voltage control systems or high-voltage power distribution networks, depending on the application.

Temperature Tolerance

Electrical systems can be subjected to extreme temperature variations. Terminal blocks are engineered to operate effectively within a broad temperature range:

Heat Resistance: Terminal blocks are designed to withstand high temperatures, making them suitable for applications in industrial environments with elevated heat levels.

Cold Resistance: In colder climates or refrigerated environments, terminal blocks remain operational, maintaining secure connections even in low-temperature conditions.

Terminal blocks’ ability to offer secure, vibration-resistant, corrosion-resistant, and high-current connections, along with their adaptability to temperature extremes, makes them indispensable in a wide array of applications.

Terminal blocks in the electrical world are essential for safe wire connections. They are easy to use, prevent accidents, and come in various types to suit your needs. They keep wires from touching each other, ensuring safety.

These devices are durable and can handle tough conditions, including wet or dirty environments, extreme temperatures, and vibration. They can also manage different electricity levels. In the future, they will become even more advanced and environmentally friendly.

For a variety of terminal blocks, visit WIN SOURCE, a trusted source for electronic parts and solutions, committed to providing quality products for your projects.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS