* Question

How Is a DP Master Configured for Intelligent Slave–Master Communication in PROFIBUS DP?

* Answer

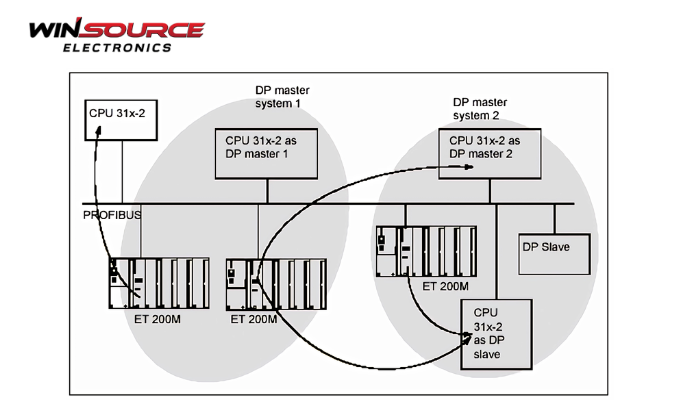

In PROFIBUS DP systems, intelligent slave–master communication refers to scenarios where an intelligent DP slave (such as a PLC, drive controller, or communication module) can temporarily assume master-like communication behavior under the coordination of a DP Master.

This functionality is typically realized through DP-V1 extensions, acyclic communication, or logical master–slave coordination, rather than by physically changing the bus master role.

1. Understanding the Communication Model

Traditional PROFIBUS DP

- One DP Mastercontrols bus access

- Multiple DP Slavesrespond only when requested

- Communication is cyclic and deterministic

Intelligent Slave Scenario

- The slave has processing capability (CPU, firmware logic)

- The slave can initiate requests or data exchanges indirectly

- The DP Master still controls bus arbitration

In short:

Only one physical DP Master exists, but intelligent slaves can participate in extended communication models.

2. DP Master Configuration Steps

2.1 GSD File Integration

The DP Master must first load the GSD (General Station Description) file of the intelligent slave.

The GSD defines:

- Supported DP version (DP-V0 / DP-V1)

- Cyclic and acyclic data sizes

- Diagnostic and parameter channels

- Communication services supported

This step enables the master to recognize the slave’s advanced capabilities.

2.2 Enable DP-V1 Acyclic Communication

To support intelligent interaction, the DP Master is configured to enable DP-V1 services, including:

- Acyclic read/write services

- Parameter access

- Extended diagnostics

DP-V1 allows the slave to:

- Send diagnostic requests

- Exchange configuration or control data

- Trigger communication events handled by the master

2.3 Define Master–Slave Data Mapping

The DP Master configures:

- Cyclic I/O data areas

- Acyclic service channels

- Mailbox or record-based communication

This mapping ensures that:

- Time-critical data remains cyclic

- Intelligent or event-driven data uses acyclic access

2.4 Configure Interrupt and Diagnostic Handling

Intelligent slaves often generate:

- Diagnostic interrupts

- Status change notifications

- Alarm events

The DP Master must be configured to:

- Accept slave-generated diagnostics

- Process alarms correctly

- Trigger application-level responses

This is how the slave effectively “initiates” communication.

3. Master–Slave Role Coordination Mechanism

It is important to clarify:

- The DP Master always retains bus control

- Intelligent slaves do not become real masters

- Communication initiation occurs through:

- Diagnostic interrupts

- Acyclic service requests

- Predefined protocol mechanisms

This ensures:

- Deterministic bus timing

- No bus contention

- Compliance with PROFIBUS standards

4. Typical Application Scenarios

Intelligent slave–master communication is commonly used in:

- Variable-frequency drives (VFDs)

- Motion control systems

- Distributed PLC architectures

- Advanced sensor and actuator networks

For example:

- A drive reports overload conditions

- A slave PLC requests parameter updates

- A smart module triggers reconfiguration

All actions are coordinated through the DP Master.

Engineering Insight

This communication model reflects a key PROFIBUS design principle:

Centralized bus control with distributed intelligence

By allowing intelligent slaves to communicate beyond simple cyclic I/O—while still preserving master arbitration—PROFIBUS DP achieves both real-time determinism and system flexibility.

Conclusion

To configure a DP Master for intelligent slave–master communication in PROFIBUS DP:

- Import and configure the intelligent slave’s GSD file

- Enable DP-V1 acyclic communication services

- Define cyclic and acyclic data mapping

- Configure diagnostics, interrupts, and alarm handling

Although intelligent slaves can initiate events and complex interactions, the DP Master always maintains control of bus access, ensuring reliable and deterministic communication.

COMMENTS