* Question

How to design a tag antenna?

* Answer

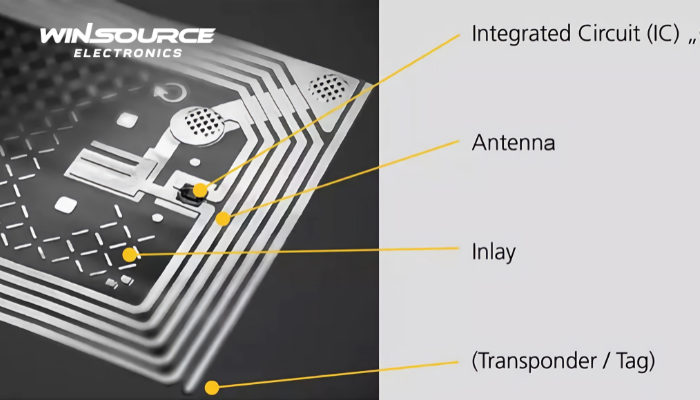

Designing a tag antenna, commonly used in RFID (Radio Frequency Identification) systems, involves several key steps to ensure it efficiently transmits and receives signals within the desired frequency range. Here is a step-by-step guide on how to design a tag antenna:

1. Determine the Application Requirements

– Frequency Band: Choose the operating frequency band (LF, HF, UHF, etc.) based on your application needs. UHF is common for long-range applications.

– Read Range: Determine the desired read range which influences the design parameters of the antenna.

– Environment: Consider the environment in which the antenna will operate (e.g., indoor, outdoor, on metal surfaces, near water, etc.), as this affects the antenna materials and design.

2. Select Antenna Type

– Dipole Antenna: Common for UHF RFID tags, offering good performance and easy integration.

– Loop Antenna: Suitable for HF and LF applications, where they can effectively create a magnetic field with a smaller footprint.

– Microstrip Antenna: Often used for compact applications; these can be designed into various shapes to fit specific spatial requirements.

3. Design the Antenna Geometry

– Simulation Software: Use antenna design software like CST Microwave Studio, ANSYS HFSS, or similar tools to model and simulate the antenna’s performance. This helps in adjusting dimensions like length, width, and shape to meet the specific frequency and impedance requirements.

– Prototyping: After simulation, create a prototype of the antenna using suitable materials (e.g., copper tape, conductive ink).

4. Matching Network

– Impedance Matching: Design a matching network to ensure that the antenna’s impedance is compatible with the RFID chip. This typically involves using components like capacitors and inductors to match the antenna impedance with the chip impedance.

– Smith Chart: Use tools like a Smith Chart to visualize and optimize the impedance matching.

5. Testing and Optimization

– Field Testing: Test the antenna in the real environment to evaluate its performance. Adjustments may be needed in terms of antenna dimensions or the matching network to optimize the range and reliability.

– Iterative Process: Refine the design through multiple iterations of testing and modification until the desired performance is achieved.

6. Finalize Design and Integration

– Integration: Integrate the antenna with the RFID chip and other system components. Consider the mechanical and environmental protection of the antenna in the final product design.

– Manufacturing: Move to manufacturing, keeping in mind scalability and cost-efficiency of the antenna production process.

7. Compliance and Quality Assurance

– Regulatory Compliance: Ensure the antenna meets all regulatory requirements for RF devices in your target markets.

– Quality Testing: Conduct quality assurance tests to ensure reliability and consistency in antenna performance across all units produced.

This process requires a mix of theoretical knowledge, practical skills, and iterative testing to ensure that the tag antenna meets the specific needs of its intended application. The design must balance performance, cost, and physical constraints to achieve an efficient and reliable solution.

COMMENTS