* Question

What are the characteristics of thermal resistance compared with thermocouples?

* Answer

Table of Contents

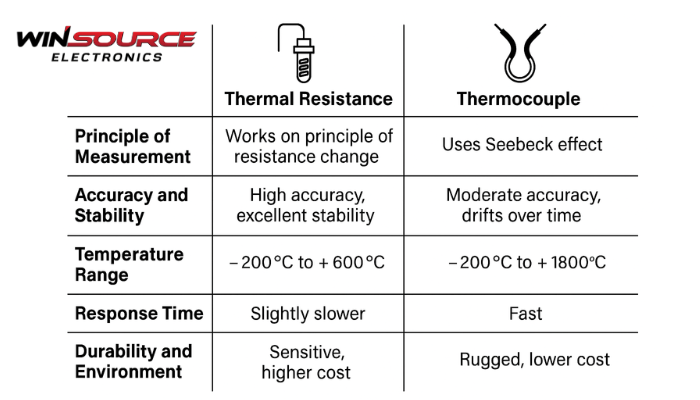

Toggle1. Principle of Measurement

Thermal Resistance (RTD, e.g., platinum resistance thermometer):

Works on the principle that the electrical resistance of a metal changes predictably with temperature.

Thermocouple:

Uses the Seebeck effect, where a voltage is generated across two dissimilar metals joined together, proportional to the temperature difference.

2. Accuracy and Stability

RTD (Thermal Resistance):

High accuracy and excellent long-term stability. Typical tolerance can be within ±0.1–0.2 °C, making them suitable for precise industrial and laboratory measurements.

Thermocouple:

Moderate accuracy (±1–2 °C or more, depending on type). Accuracy can drift with age, oxidation, and mechanical stress.

3. Temperature Range

RTD:

Typically –200 °C to +600 °C (platinum RTDs), with some special designs going slightly higher.

Thermocouple:

Much wider range, up to about –200 °C to +1800 °C (depending on type, e.g., Type K, Type R, etc.). Best choice for high-temperature environments like furnaces.

4. Response Time

RTD:

Slightly slower due to sensing element construction (wire-wound or thin-film). Best suited where precision is more important than speed.

Thermocouple:

Fast response, particularly in fine-wire or exposed-junction designs, which makes them well-suited to transient or rapidly changing temperatures.

5. Durability and Environment

RTD:

Sensitive to mechanical shock and vibration, more expensive, but very stable under controlled conditions.

Thermocouple:

Rugged, inexpensive, withstands harsh environments, but less stable over time due to drift and chemical degradation.

Summary

Thermal resistance sensors (RTDs) are preferred where high accuracy, repeatability, and stability are critical, usually in laboratory and industrial process control.

Thermocouples excel in wide-range, high-temperature, fast-response, and rugged applications, such as metallurgy, engines, and heating systems.

COMMENTS