* Question

What issues should be considered for polymer substrate materials for OLEDs?

* Answer

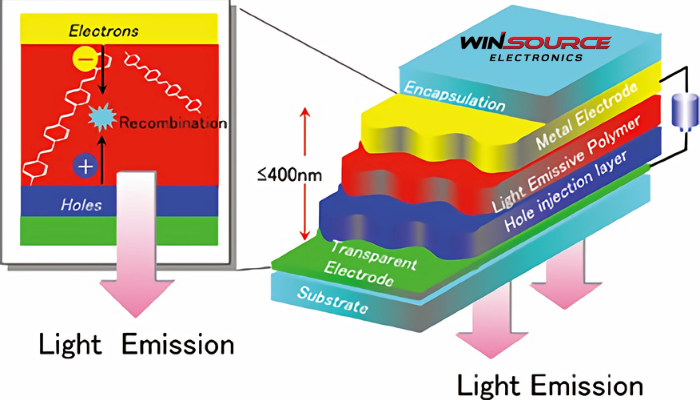

When selecting polymer substrate materials for OLEDs (Organic Light Emitting Diodes), several key issues need to be considered to ensure optimal performance, durability, and manufacturability of the OLED devices. Here are the main considerations:

1. Thermal Stability:

– Heat Resistance: The polymer substrate must withstand the high temperatures involved in OLED fabrication and operation without degrading. This includes processes such as thermal evaporation or annealing.

– Thermal Expansion: The coefficient of thermal expansion (CTE) of the polymer should be compatible with the OLED materials to prevent delamination or cracking due to thermal cycling.

2. Optical Properties:

– Transparency: High optical transparency in the visible spectrum is essential for substrates used in OLED displays to ensure maximum light output.

– Refractive Index: The refractive index of the substrate should be matched to the OLED layers to minimize reflection losses and improve light outcoupling.

3. Mechanical Properties:

– Flexibility: For flexible OLED applications, the substrate must be highly flexible and capable of withstanding repeated bending and deformation without cracking or losing its properties.

– Tensile Strength: The substrate should have adequate tensile strength to handle manufacturing processes and mechanical stresses during use.

4. Barrier Properties:

– Moisture and Oxygen Barrier: Polymers generally have poor barrier properties against moisture and oxygen, which are detrimental to OLED performance and lifespan. Therefore, substrates often require additional barrier coatings or encapsulation layers to protect the OLED materials.

– Permeability: Low permeability to gases and liquids is crucial to prevent degradation of the OLED materials.

5. Chemical Stability:

– Resistance to Chemicals: The substrate must be resistant to chemicals used in the OLED fabrication process, including solvents, acids, and bases.

– Inertness: Chemical inertness to prevent any adverse reactions with the OLED materials or other layers in the device structure.

6. Surface Properties:

– Smoothness: A smooth surface is critical for uniform OLED layer deposition and to avoid defects that could affect device performance.

– Surface Energy: Appropriate surface energy to ensure good adhesion of the OLED layers and other functional coatings.

7. Electrical Properties:

– Insulation: The polymer substrate should be electrically insulating to prevent short circuits and interference with the OLED’s operation.

8. Manufacturability:

– Processing Compatibility: The substrate material must be compatible with existing OLED manufacturing processes, such as roll-to-roll processing for flexible displays.

– Scalability and Cost: The material should be cost-effective and scalable for mass production to make OLED devices commercially viable.

9. Environmental and Safety Considerations:

– Recyclability: Consideration of the environmental impact and recyclability of the polymer substrate.

– Non-toxicity: Ensuring that the materials used do not pose health risks during manufacturing or use.

By carefully evaluating these factors, the selection of polymer substrate materials can be optimized to enhance the performance, durability, and commercial viability of OLED devices.

COMMENTS