Capacitors are indispensable components in electrical circuits that store and release electrical energy. Among the diverse capacitors, ceramic capacitors stand out as a popular choice. Their widespread use can be attributed to several advantages they bring to electronic systems.

Ceramic capacitors offer relatively high capacitance values in a compact size, low equivalent series resistance (ESR), and excellent high-frequency performance. Their reliability, stability, and affordability also make them suitable for various applications, from consumer electronics to induction furnaces.

Continue reading to learn more about ceramic capacitors, their types, applications, etc.

What are Ceramic Capacitors?

Due to their recognized insulating properties, ceramic capacitors hold historical significance as one of the earliest materials employed in capacitor production. They are electronic components that use a ceramic material as a dielectric, positioned between two conductive plates. The ceramic capacitor’s polarity is zero, and it exists in a non-polarized form. As these capacitors utilize ceramic as a dielectric, they have a fixed capacitance value.

Here’s the symbol of a capacitor that’ll help you identify it in a circuit:

Characteristics of Ceramic Capacitors

Let’s look at a few important characteristics of ceramic capacitors:

Voltage and Power Handling

Ceramic capacitors exhibit remarkable versatility in handling voltage and power.

- Power ceramic capacitors are engineered to endure voltages ranging from 2kV to an impressive 100kV, boasting power specifications well beyond 200 volt-amperes.

- Conversely, smaller Multi-Layer Ceramic Capacitors (MLCCs), commonly employed in printed circuit boards, are rated for voltages spanning a few to several hundred volts.

Precision and Tolerances

These capacitors are divided into two classes, each catering to unique requirements:

Class 1

Class 1 capacitors find application in scenarios demanding high stability and minimal losses. Notably, the NP0 series capacitor demonstrates a remarkable capacitance thermal stability of ±0.54% across the entire temperature spectrum, from -55 to +125 °C. Tolerances for the nominal capacitance value can be as tight as 1%.

Class 2

Class 2 capacitors, recognized for their high capacitance per volume, are used in less sensitive applications. Their thermal stability typically hovers around ±15% in the operating temperature range, with nominal value tolerances averaging around 20%.

Types of Ceramic Capacitors

Here are the types of ceramic capacitors, and you can choose the one that best suits your requirements:

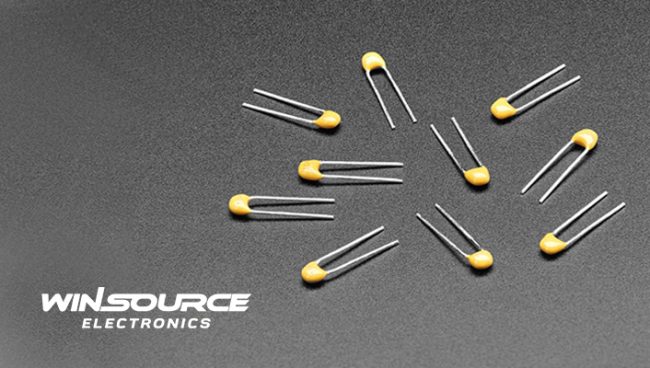

Ceramic Disc Capacitors

Ceramic disc capacitors have a simple yet robust design. They consist of a ceramic disc coated with silver on both sides. Their capacitance ranges from 10pF to 100μF, offering versatility with a diverse array of voltage ratings spanning from 16 volts to 15 kV and beyond.

Due to their compact size and cost-effectiveness, ceramic disc capacitors are used in various electronic circuits. They are suitable for filtering and coupling applications, offering reliability in a concise form factor.

Multi-Layer Ceramic Capacitors (MLCCs)

Multi-layer ceramic Capacitors (MLCCs) are a more advanced and widely used form of ceramic capacitor. They are made by placing multiple layers of ceramic material, like finely powdered paraelectric and ferroelectric materials, between metal contacts in a meticulous layering process.

They distinguish themselves by comprising 500 layers or more, with a minimum layer thickness of approximately 0.5 microns. This intricate layering contributes to achieving higher capacitances within a compact structure. Technological advancements continually reduce layer thickness, enabling MLCCs to attain progressively higher capacitances for the same volume. They are quite popular, and their market is expected to hit USD 17.44 billion by 2028.

Best Ceramic Capacitor Options

Here are the best ceramic capacitor options you can try for various applications:

GRT21BC71E106KE13L

The GRT21BC71E106KE13L capacitor is AEC-Q200 qualified, meeting the stringent standards for automotive applications. Rigorously tested and proven, it ensures reliability in the demanding automotive industry. With an expansive operating temperature range from -55°C to +125°C, this capacitor is versatile, excelling in various applications, even harsh environments.

Its high ripple current makes it particularly suitable for various applications where it can adeptly handle fluctuating currents. It also has a remarkable mean time to failure (MTTF) exceeding 10 billion hours. Hence, it is an exceptionally reliable choice for diverse applications demanding durability.

959341-C0805C472J1GACTU

The Kemet 959341-C0805C472J1GACTU is a ceramic capacitor with a capacitance of 4.7 nF and a robust voltage rating of 100 V. Designed for convenience, it comes in a cut-tap package and is easily surface-mounted. This capacitor’s moisture sensitivity level (MSL) is 1, indicating excellent moisture resistance.

It falls under the ECCN classification of EAR99, simplifying export considerations. With a tolerance of 5 percent and a temperature coefficient of 30 ppm/°C, this capacitor ensures precision in electrical circuits. Operating seamlessly up to 125 °C, it caters to applications demanding stability even in elevated temperatures.

Advantages of Ceramic Capacitors

Here are a few advantages of ceramic capacitors that make them stand out among other types:

- Compact Structure: Ceramic capacitors boast a compact structure, making them highly efficient in utilizing space within electronic circuits.

- Cost-Effective: One of the ceramic capacitors’ standout benefits is their cost-effectiveness. They are economical for various electronic projects, offering budget-friendly solutions without sacrificing reliability.

- Tolerant to Signal Interference: A ceramic capacitor exhibits a commendable tolerance to signal interference, making it resilient in environments prone to external disruptions.

Applications of a Ceramic Capacitor

Let’s look at a few applications of a ceramic capacitor:

- Ceramic capacitors find application in transmitter stations where their compact size and high capacitance values contribute to the efficient transmission of signals.

- A ceramic capacitor plays a vital role in induction furnaces by providing reliable energy storage and release.

- Ceramic capacitors are employed in high-voltage laser power supplies due to their ability to handle elevated voltage levels.

Ceramic capacitors are reliable, versatile, and affordable than electrolytic capacitors. They are helpful in various applications ranging from induction furnaces to transmitter stations. If you are a business searching for authentic and high-quality capacitors, WIN SOURCE has you covered.

We have direct comments with a network of manufacturers crafting authentic and durable electronic components. Our team will get you connected with them, ensuring you get your hands on the best capacitors. Not only this, we are also available to help you with product delivery and other matters. Contact us today and make your journey to finding the right capacitors easy!

© 2024 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS