Table of Contents

ToggleWhat Are Ceramic Capacitors?

Ceramic capacitors are fundamental electronic components used in a wide range of electronic circuits. They store electrical energy in the form of an electric field, which is created between two conductive plates separated by a dielectric material. The dielectric in ceramic capacitors is made of ceramic materials, typically composed of ceramic compounds like barium titanate or various ceramic formulations.

Ceramic capacitors have several advantages that make them attractive for various electronic applications:

High Capacitance: Ceramic capacitors can provide a high capacitance value in a compact form factor, which is ideal for space-constrained applications.

Low ESR (Equivalent Series Resistance): Ceramic capacitors have low ESR, which allows them to handle high-frequency signals efficiently.

Fast Charging and Discharging: Due to their low ESR and high capacitance, ceramic capacitors can charge and discharge rapidly, making them suitable for applications that require quick response times.

Durability: Ceramic capacitors are robust and can withstand a wide range of environmental conditions, including temperature extremes and vibration.

Cost-Effective: They are often cost-effective compared to some other capacitor technologies, making them a practical choice for mass-produced electronic devices.

Types of Ceramic Capacitors

1. MLCCs (Multilayer Ceramic Capacitors)

Multilayer Ceramic Capacitors (MLCCs) are one of the most common and versatile types of ceramic capacitors. These components are characterized by their multilayered structure, which allows for a compact design with high capacitance. MLCCs find widespread use in various electronic devices, from smartphones to laptops, and even in high-frequency applications due to their low equivalent series inductance (ESL).

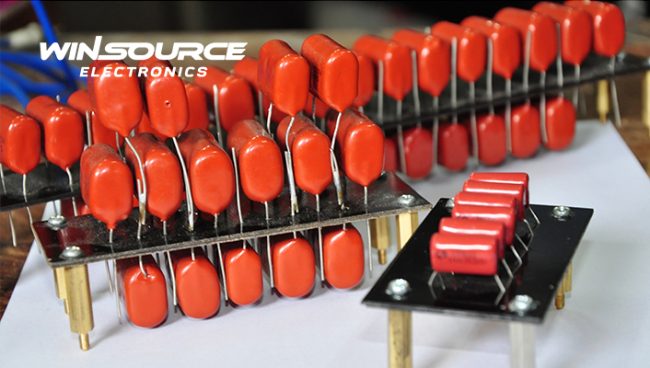

2. Disc Capacitors

Disc capacitors, also known as ceramic disc capacitors, are a classic type of ceramic capacitor. They feature a simple, circular design with leads for easy through-hole mounting. Disc capacitors are often used in lower-frequency applications and for noise suppression due to their stable and predictable performance.

3. Ceramic Chip Capacitors

Ceramic chip capacitors are small, surface-mount components that come in a variety of shapes and sizes. These capacitors are widely used in modern PCB (Printed Circuit Board) designs, making them suitable for miniaturized and densely packed electronic assemblies.

Each type of ceramic capacitor is tailored for specific applications, based on factors like size, capacitance, and voltage requirements.

Dielectric Materials in Ceramic Capacitors

The dielectric material within a ceramic capacitor plays a pivotal role in determining its performance. The most common dielectric materials used in ceramic capacitors are barium titanate and various ceramic formulations.

Different dielectrics exhibit distinct properties that impact the capacitor’s behavior.

- Barium Titanate: This dielectric material is known for its high dielectric constant, which results in a high capacitance per unit volume. Barium titanate capacitors are suitable for applications requiring high capacitance and compact design.

- Various Ceramic Formulations: Manufacturers often fine-tune ceramic capacitor formulations to meet specific requirements, such as achieving higher temperature stability or lower losses at high frequencies. These tailored formulations are crucial for addressing the diverse needs of modern electronics.

Ceramic Capacitors in High-Frequency Applications

The low ESL (Equivalent Series Inductance) of ceramic capacitors makes them invaluable in high-frequency electronic circuits. This property reduces unwanted inductive effects and ensures stable performance in applications such as RF (Radio Frequency) and microwave circuits. The ability to maintain stable capacitance and low losses at high frequencies positions ceramic capacitors as essential components in next-gen electronics.

Furthermore, ceramic capacitors exhibit excellent thermal stability and can withstand a wide range of operating temperatures, making them suitable for various harsh environmental conditions. Their compact size and high capacitance values also contribute to their popularity in modern high-frequency applications, where space-saving and high-performance components are crucial for meeting the demands of rapidly advancing technology.

As electronic devices continue to push the boundaries of frequency and performance, ceramic capacitors are expected to play an increasingly significant role in shaping the future of electronic engineering.

Ceramic Capacitors in Automotive and Industrial Applications

Ceramic capacitors play a critical role in the automotive and industrial sectors. In the automotive industry, they are used in engine control units (ECUs), airbag systems, infotainment systems, and more. Their reliability, stability, and compact size make them suitable for these demanding environments.

In industrial applications, ceramic capacitors find use in power electronics, motor drives, and automation systems. Their high capacitance and low ESR ensure smooth and efficient operation in these settings.

Applications in Next-Gen Electronics

The exceptional characteristics of AVX ceramic capacitors make them indispensable in various applications within next-generation electronics:

1. Mobile Devices

Ceramic capacitors from AVX are commonly found in smartphones and tablets, where miniaturization, fast charging, and efficient power management are essential.

2. Automotive Electronics

With the increasing complexity of automotive electronics, ceramic capacitors are vital for stability and performance in critical systems such as engine control units and infotainment systems.

3. 5G Technology

The deployment of 5G networks relies on high-frequency electronics, where low ESL ceramic capacitors play a significant role in signal transmission and reception.

4. IoT Devices

The Internet of Things (IoT) is reliant on small, power-efficient components, making ceramic capacitors from AVX a go-to choice for IoT device manufacturers.

5. Aerospace and Defense

In aerospace and defense applications, reliability is paramount, and AVX ceramic capacitors meet the stringent requirements of these industries.

AVX’s ceramic capacitors are at the forefront of next-gen electronics, enabling manufacturers to design smaller, faster, and more efficient electronic devices. Their commitment to advanced dielectric materials, low ESL, and miniaturization has positioned them as a trusted partner in the ever-advancing world of electronics. As technology continues to evolve, AVX remains dedicated to providing innovative solutions that empower the electronic devices of tomorrow.

For a comprehensive range of AVX ceramic capacitors and other electronic components, visit WIN SOURCE, your trusted source for high-quality electronic components and solutions.

WIN SOURCE provides a wide selection of ceramic capacitors, ensuring that you have access to the latest and most innovative components for your electronic projects and applications.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS