The NTC Meaning

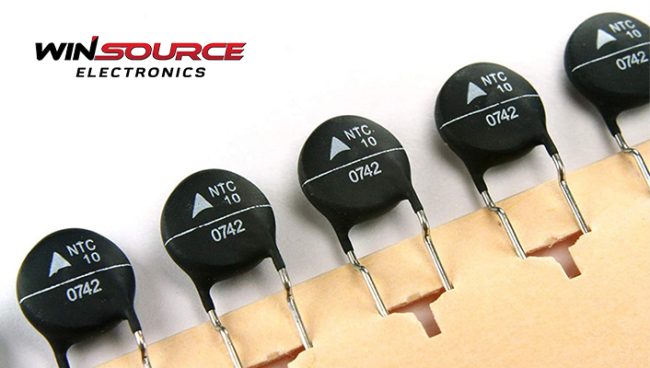

The term NTC stands for Negative Temperature Coefficient, and it is a key attribute of the thermistor’s behavior. NTC thermistors exhibit a decrease in resistance as the temperature rises. This characteristic makes them particularly useful in applications where precise temperature sensing and control are essential.

NTC thermistors are made from semiconductor materials with a specific type of doping that results in their unique thermal response. As the temperature increases, the number of charge carriers in the semiconductor material also increases, leading to a reduction in resistance. This property is harnessed in a variety of applications across industries.

NTC Thermistor Technical Parameters

To fully comprehend the capabilities of NTC thermistors, it’s crucial to delve into their technical parameters. The following are key parameters that define the performance of NTC thermistors:

Resistance-Temperature Relationship:

The resistance of NTC thermistors is highly dependent on temperature. This relationship is often characterized by a mathematical equation, such as the Steinhart-Hart equation, allowing engineers to precisely determine the temperature based on the measured resistance.

Beta Value (β):

The Beta value is a critical parameter that describes the shape of the resistance-temperature curve. It is used to model the behavior of NTC thermistors over a specific temperature range. The Beta value is essential for accurately calculating temperature in various applications.

Temperature Coefficient of Resistance (α):

The temperature coefficient of resistance, denoted by α, expresses the percentage change in resistance per degree Celsius. Understanding this parameter is crucial for predicting how the NTC thermistor’s resistance will change with temperature variations.

Applications of NTC Thermistors

Conversion Power Supply:

NTC thermistors are commonly used in conversion power supplies to stabilize and control the temperature of electronic components. They help enhance the efficiency and reliability of power supply circuits.

Switch Power and UPS Power:

In switch power and uninterruptible power supply (UPS) systems, NTC thermistors are employed for temperature sensing and control, preventing overheating and ensuring the safe and stable operation of these critical components.

Electric Heater Control:

NTC thermistors play a crucial role in electric heater control systems by providing accurate temperature feedback. This ensures precise temperature regulation, improving the efficiency and safety of electric heating systems.

Electronic Energy-Saving Lamps and Electronic Ballast:

NTC thermistors are integrated into electronic energy-saving lamps and ballast circuits to regulate the operating temperature, optimize performance, and extend the lifespan of these lighting systems.

Power Circuit Protection in Electronic Equipment:

NTC thermistors are employed in various power circuit protection applications, such as overcurrent protection and inrush current limiting, safeguarding electronic equipment from damage during power fluctuations and startup.

Filament Protection of CRT:

In cathode-ray tube (CRT) displays, NTC thermistors are utilized for filament protection, preventing excessive current during startup and ensuring the longevity of the CRT.

Bulb and Other Lighting Lamps:

NTC thermistors contribute to the reliability and efficiency of bulbs and other lighting lamps by regulating the temperature, especially during initial power-up, thereby extending the life of these lighting sources.

Electrical Characteristics of NTC Thermistors

Zero Power Resistance:

The zero-power resistance of an NTC thermistor refers to its resistance at a specified reference temperature, typically at 25°C. This parameter is crucial for accurately calibrating temperature sensors and ensuring stability in temperature-controlled applications.

Max. Steady State Current:

The maximum steady-state current represents the highest continuous current that an NTC thermistor can handle without experiencing excessive self-heating. This parameter is vital for applications where current levels need to be carefully managed to prevent overheating and ensure reliable operation.

Thermal Dissipation Constant:

The thermal dissipation constant, denoted as δ, characterizes the ability of an NTC thermistor to dissipate heat. It is a measure of how efficiently the thermistor can transfer heat to its surroundings, influencing its temperature response and overall performance.

Thermal Time Constant:

The thermal time constant (τ) indicates the time it takes for an NTC thermistor to reach a specified percentage (often 63.2%) of its final temperature in response to a step change in temperature. A lower thermal time constant is desirable in applications where rapid temperature sensing and response are critical.

Operating Temperature Range:

The operating temperature range defines the minimum and maximum temperatures within which an NTC thermistor can operate effectively. This parameter is crucial for selecting the appropriate thermistor for specific applications, ensuring reliable performance under varying temperature conditions.

So, as far as NTC meaning is concerned, it helps achieve precise temperature control and measurement. Their unique characteristics, such as the negative temperature coefficient, stability, and fast time response, position them as fundamental components in electronic circuits across various industries.

If you’re on the lookout for high-quality NTC thermistors for cutting-edge electronic applications, you can turn to WIN SOURCE. As a leading electronic component distributor, WIN SOURCE provides a comprehensive range of NTC thermistors, ensuring access to high-quality components that meet the stringent requirements of modern electronic systems.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS