* Question

How does a wavelength modulated fiber sensor work?

* Answer

A wavelength modulated fiber sensor operates by detecting changes in the wavelength of light propagating through a fiber optic cable. These changes are induced by variations in external physical conditions such as temperature, pressure, strain, or chemical composition. Here’s an explanation of how it works:

Core Principles:

1. Light Source and Wavelength Encoding:

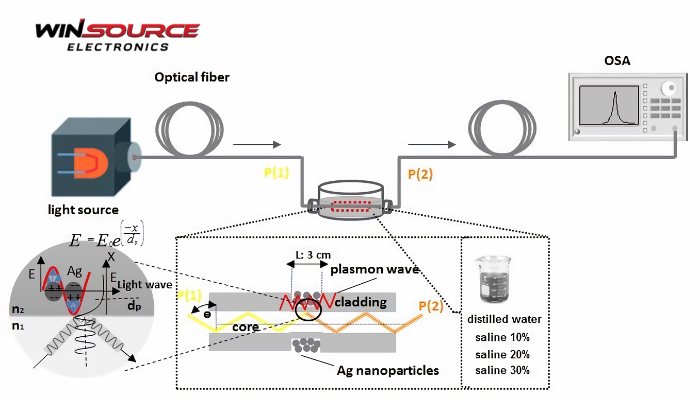

– A light source (e.g., a laser or LED) injects light into the fiber optic cable.

– The light interacts with a sensing element (fiber Bragg grating, Fabry-Pérot interferometer, or other optical components) designed to encode external changes into wavelength shifts.

2. Sensing Mechanism:

– External physical changes alter the optical properties of the sensing element. These changes affect:

– Refractive Index: Modifies the propagation characteristics of light.

– Physical Dimensions: Changes in length, strain, or pressure alter the path or structure of the sensing element.

– The result is a shift in the wavelength of the light reflected, transmitted, or interfered.

3. Modulation and Reflection/Transmission:

– For example, in a Fiber Bragg Grating (FBG) sensor:

– The grating reflects a specific wavelength (Bragg wavelength).

– External conditions such as strain or temperature shift the Bragg wavelength proportionally to the applied effect.

4. Detection and Processing:

– The modified wavelength is captured by a spectrometer, photodetector, or other optical analysis tools.

– By analyzing the wavelength shift, the external physical condition can be quantified.

Advantages of Wavelength Modulation:

– High Sensitivity: Small changes in wavelength correspond to fine measurements.

– Multiplexing Capability: Multiple sensors can operate on a single fiber using distinct wavelengths.

– Immunity to Power Loss: Since information is encoded in wavelength rather than intensity, it is less affected by signal degradation.

– Robustness: Resistant to electromagnetic interference and harsh environments.

Typical Applications:

– Structural Health Monitoring: Strain and stress measurement in bridges, buildings, and aircraft.

– Temperature Measurement: In environments like power plants or chemical processing facilities.

– Pressure Sensing: In pipelines or underwater.

– Chemical Sensing: Detecting specific substances via refractive index changes.

In summary, wavelength modulated fiber sensors work by converting external physical changes into precise wavelength shifts, providing reliable, sensitive, and accurate measurements for a wide range of applications.

COMMENTS