Electronic devices play an indispensable role in modern society. From smartphones to computers, from household appliances to industrial automation systems, the range of electrical appliances is becoming more and more extensive. However, how appliances work and what’s inside is still uncharted territory for most people. This article will take a deeper look at how electrical appliances work, with a focus on the fabrication of load storage to gain a more complete understanding of the core mechanisms of electronic devices.

Table of Contents

ToggleThe working principle of electrical appliances

Current and voltage

Current and voltage are the basic physical quantities for electrical work. Current refers to the amount of charge that passes through a conductor per unit time, while voltage refers to the energy that a charge possesses when it is transmitted in a circuit. The relationship between current and voltage is described by Ohm’s law, which states that current is equal to the ratio between voltage and resistance. By controlling the magnitude and direction of current and voltage, electrical appliances can achieve different functions and operations.

Circuits and Components

Electrical current and voltage in electrical appliances are controlled and transmitted through electrical circuits. A circuit is a network of electronic components (such as resistors, capacitors, and inductors) and connecting wires. Electronic components play different roles in circuits, such as resistors to control current flow, capacitors to store charge, and inductors to store and release energy. The selection and configuration of electronic components determine the function and performance of the circuit.

Logic Gates and Integrated Circuits

Logic gates are the basic building blocks in electronic devices. They are composed of transistors and can perform logic operations (such as AND gates, OR gates, NOT gates, etc.). A logic gate outputs a definite result by performing logical operations on multiple input signals. An integrated circuit integrates a large number of logic gates and other electronic components on a chip to achieve more complex functions. The manufacturing process of integrated circuits involves advanced lithography and deposition techniques that allow more electronic components to be packed into a smaller space.

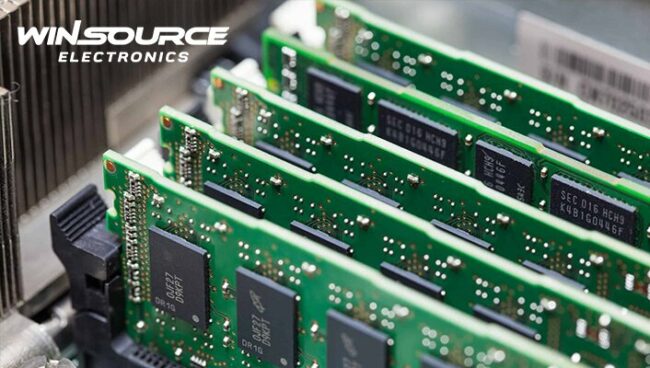

Fabrication of Load Storage

The concept of load memory

Load memory is an electronic component used to store and read data. It usually consists of devices such as transistors and capacitors. Static Random Access Memory (SRAM) and Dynamic Random Access Memory (DRAM) are two common types of load memory.

Static Random Access Memory (SRAM) which uses flip-flop circuits to store each bit of data. A flip-flop is an electronic switch consisting of multiple transistors. Each memory cell in SRAM contains a pair of complementary flip-flops, representing bit 0 and bit 1, respectively. By controlling the switching state of flip-flops, SRAM can store and maintain data in memory cells. SRAM has fast read and write speeds and low power consumption, so it is widely used in applications that require high performance and fast access, such as cache memory.

Dynamic Random Access Memory (DRAM) which uses capacitors to store data. Each memory cell in DRAM consists of a transistor and a capacitor. The data is stored in the state of charge in the capacitor, discharging the capacitor when the bit is 0 and charging the capacitor when the bit is 1. However, capacitors lose their charge over time, so they need to be refreshed periodically to maintain data integrity. DRAM is widely used in applications such as mass storage and main memory due to its higher storage density and cost-effectiveness.

Manufacturing process

The manufacturing process of load storage involves several complex steps, including

(1) Wafer preparation: Layers of metal and insulating layers are formed on silicon wafers through techniques such as chemical vapor deposition and physical evaporation.

(2) Transistor manufacturing: use photolithography technology and ion implantation to pattern the structure of the transistor on the silicon wafer, and perform doping and activation treatment.

(3) Metal interconnection: use thin film deposition and electroplating processes to establish metal wire connections between transistors and form a multilayer interconnection structure.

(4) Testing and packaging: Perform functional tests on the manufactured chips, including electrical performance tests and storage function tests, and package them to protect the chips and facilitate integration into actual devices.

In conclusion

The working principle of electrical appliances and the fabrication of load memories are important topics in the field of electronics. A deep understanding of how electrical appliances work helps us better use and maintain electronic devices, while the fabrication of load memory is the key to high performance and high density storage. Through continuous technological innovation and improvement of manufacturing process, electronic equipment will achieve greater breakthroughs in function and performance, bringing more convenience and innovation to people’s life and work.

COMMENTS