In modern electronic engineering, electronic components are an indispensable part of electronic devices, and the necessity of testing electronic components is self-evident. Whether from the perspectives of manufacturers, engineers, individual makers, educational institutions, or end-users, testing electronic components is essential. Let’s explore why testing electronic components is necessary from these different perspectives.

From the perspective of manufacturers, testing electronic components is a crucial step in ensuring product quality and meeting customer demands. In the process of electronic product manufacturing, manufacturers need to ensure that the electronic components used are compliant and free of defects or defects.

If there are component issues, it may affect the performance and reliability of the entire product, and even cause product failures or returns, which will have a negative impact on the manufacturer’s reputation and profit. Therefore, testing electronic components can help manufacturers detect and solve these problems before products enter the market. Testing can detect whether the components meet the specifications and identify any defects or defects that may exist. In addition, testing can optimize the manufacturing process, identify issues on the production line, and make timely adjustments and corrections, thereby improving production efficiency and product quality.

From the perspective of engineers, testing electronic components is an important step in ensuring circuit performance and stability. The selection and use of electronic components depend on circuit design and application scenarios, and different component parameters and qualities may have different effects on circuit performance.

Therefore, when designing and developing circuits, engineers need to test and verify the selected electronic components to ensure that they can operate normally under different voltage, temperature, and environmental conditions and meet the design specifications. Testing electronic components can help engineers identify possible issues and defects, such as capacitor leakage, inductor short-circuits, transistor distortion, and so on. By analyzing and solving these issues, engineers can optimize circuit design and improve circuit performance and reliability. In addition, testing electronic components can also verify the design and simulation results of circuits to ensure that they are consistent with actual operating conditions, thereby laying the foundation for the final implementation of the circuit.

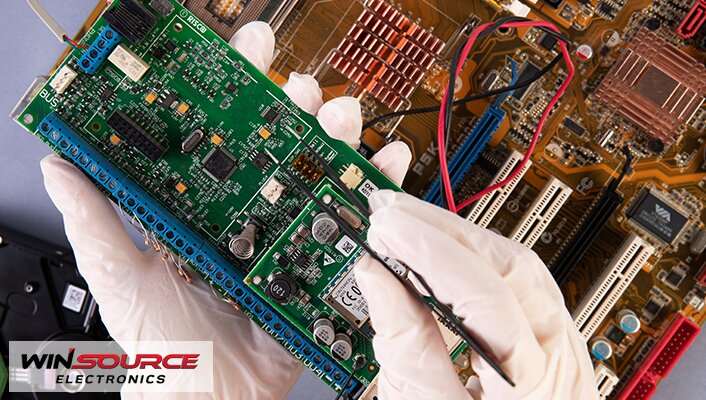

From the perspective of individual makers, testing electronic components is a critical step in ensuring circuit stability and reliability. When making circuit boards, there may be errors or incompatible components that, if not tested, may go unnoticed and cause the entire circuit board to fail. Additionally, during use, components may age or become damaged, and without testing tools, it is impossible to quickly locate problems and replace faulty components.

From the perspective of end users, testing electronic components ensures high quality and reliability of products. For consumer electronics, testing electronic components helps users identify potential problems such as overheating, battery damage, and circuit faults, allowing for timely resolution before bigger issues arise. In industrial electronic equipment, the importance of testing electronic components is even more significant, as these devices are typically used in critical production and manufacturing processes, and any issues can lead to production downtime and decreased production line efficiency.

By testing electronic components, users can identify potential problems in a timely manner and take measures to resolve them, thereby ensuring normal operation of production. Additionally, testing electronic components can help users determine if products need maintenance or replacement, prolonging the life of products and increasing work efficiency. By understanding the actual working status and performance of products, users can better utilize them and avoid unnecessary trouble caused by a lack of understanding of the products.

From the perspective of educational institutions, testing electronic components is also very necessary. Teachers can use testing tools to teach students how to test and diagnose faulty electronic components. This helps students understand how circuits work and how to identify and solve problems. Additionally, testing electronic components can help teachers monitor and maintain the stability and reliability of laboratory equipment, ensuring that students can complete experiments and projects smoothly.

In summary, testing electronic components is an indispensable step in modern electronic engineering. Whether from the perspective of manufacturers, engineers, individual makers, educational institutions, or end users, testing electronic components can ensure product quality, performance, and reliability. Therefore, we need to attach importance to the importance of testing electronic components and take appropriate testing measures to ensure the quality and reliability of components.

COMMENTS