Pneumatic fittings have become increasingly popular over recent years both because of their dependability and low price. Essential in a wide range of compressed air systems, fittings such as the PC602 provide a cleaner, safer alternative to electrical and hydraulic options. Easy to use, these versatile components enjoy an array of industrial and commercial applications, and their versatility allows them to be employed in some of the harshest environments.

Explaining What a PC602 Does

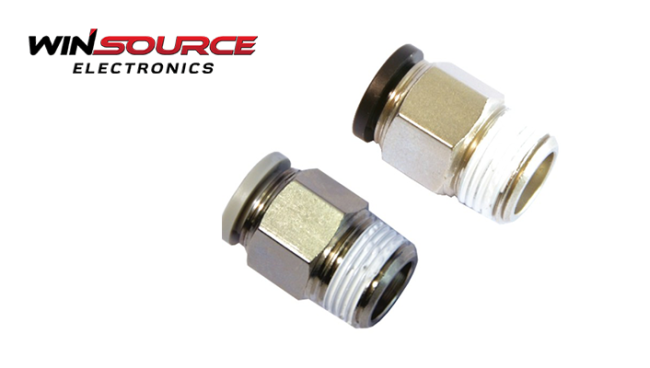

Essentially, AIRTAC PC602 pneumatic push lock male connector fitting is a small yet mighty component that’s used in machinery and automation. These systems use compressed air to transmit and control energy, and you’ll find them being used everywhere, from complex manufacturing machines to the automatic doors you walk through at your local supermarket.

Other applications of this popular component include:

- Automation Systems – Automated factory assembly lines in pharmaceutical plants and bottling factories (to name but two)use pneumatic fittings like these to help control the movement of mechanical parts.

- Vehicle Maintenance– Visit garages across the country, and you’ll find pneumatic components being employed in tools such as air wrenches, allowing mechanics to work more efficiently.

- Packaging Machinery – Another popular application is in the packaging industry. With exacting control, they help goods to be sealed and presented for sale swiftly and precisely.

- Medical Devices – In the hospital and healthcare sector, these pneumatic fittings are essential in the function of a range of medical devices, especially those requiring delicate and controlled movement.

Key Features & Benefits of the AIRTAC-PC602

Pneumatic technologies have existed since the end of the 1900s. However, it was during the Industrial Revolution at the start of the 20th century that they began evolving into their current form. One of the primary benefits of this particular AIRTAC component is its high levels of durability due to its robust construction.

This allows it to withstand intense pressures and temperatures found in the most challenging working environments. Other features on offer:

- Compact, space-saving size– the PC602 is compact, meaning it’s able to fit more easily inside complex machinery.

- Leak-proof design– the threaded part of this fitting is coated with sealant and combined with the sealing gasket on the M5 thread, it ensures leaks are avoided over the connection thread.

- Corrosion Resistant– this fitting is also nickel-plated, meaning it’s resistant to both corrosion and pollution.

Acting as a junction between various different components in a pneumatic system, a tight leak-proof connection is provided – crucial for maintaining pressure. Also compatible with a variety of hoses and tubing sizes, it removes the need to source specific connectors.

The Pros of PC602 Fittings vs Hydraulic/Electrical Options

When comparing pneumatic fittings to hydraulic and electrical connections, they’re generally safer due to the lack of combustible hydraulic fluids and risk of electric shock. They also enjoy several other advantages.

- Simplicity & Ease of Use– Pneumatic systems and their fittings are often simpler in design and easier to operate and maintain. They don’t require the complex pumps, reservoirs, and filters needed in hydraulic systems or the intricate wiring and circuitry of electrical systems.

- Cleanliness – Being powered by air, any leaks that occur don’t present the same clean-up issues that hydraulic fluid leaks can.

- Cost-effectiveness – Typically speaking, pneumatic fittings are much less expensive to install and maintain versus their electrical and hydraulic counterparts.

- Speed of Operation – Pneumatic systems are able to operate at high speeds, making them suitable for applications that call for rapid movement and lightweight operation.

Its strengths lie in its durability, ease of use, and cost-effectiveness, making it a solid choice for many standard pneumatic applications.

The Cons of PC602 Fittings vs Hydraulic Options

As with any product, there are limitations that come along with the benefits of this component. For instance, compressed air can be less effective at power transmission compared to hydraulic fluids, meaning they’re not always suited to heavy-duty applications.

Due to the nature of compressed air, connectors such as these don’t offer the same precision in terms of control of speed and force. The energy efficiency of pneumatics can also be limited, particularly over longer distances or when continuous force is required.

Pneumatic systems can also be noisier than hydraulic connectors, and if there’s any impurity or moisture in the air being used, it can result in system wear and tear.

…and versus Electrical Options

Again, pneumatic connectors like the PC602 are at a disadvantage in comparison to electrical options when it comes to consistent power delivery and energy efficiency. Also, electrical connectors provide more sophisticated options for variable speed control and programmable logic – something that’s more difficult to achieve with pneumatics.

Air quality control is an aspect that needs to be monitored with air compression-based systems, too, which is maintenance that’s not required to the same degree with electrics.

When you need a corrosion-resistant, clean, easy-to-use and cost-effective option for a multitude of industrial applications, then the AIRTAC PC602 pneumatic push lock male connector fitting is the product of choice.

At WIN SOURCE, we offer a range of high-quality components needed for the electrical control systems that are employed alongside pneumatic devices like those we’ve spoken about here today. As such, we’re your reliable source for electrical components of all shapes and sizes.

COMMENTS