Pressure sensors are vital components in various industrial, automotive, and consumer applications. They provide accurate measurements of pressure levels in different environments, allowing for precise control and monitoring systems. As technology evolves, so does the demand for more advanced and accurate pressure sensors.

One such sensor is the Murata SCP1000-D01 digital absolute pressure sensor. This sensor offers unparalleled precision and performance, making it a popular choice for barometric pressure measurement and altimeter applications. In this article, we will take a closer look at the SCP1000-D01 and its evolution in the pursuit of accuracy.

Table of Contents

ToggleEvolution of Pressure Sensors

Pressure sensors have come a long way since their invention in the early 20th century. Initially used in industrial applications, they have now found their way into various consumer devices such as smartphones and wearables. However, the demand for more accurate and reliable pressure sensors has continued to grow.

Traditionally, pressure sensors used piezoelectric or strain gauge technologies, which were limited in terms of accuracy and reliability. As technology evolved, new sensing techniques, such as capacitive and piezoresistive, were developed, allowing for better accuracy and performance. This paved the way for the development of advanced pressure sensors like the SCP1000-D01.

The Murata SCP1000-D01

The Murata SCP1000-D01 is a digital absolute pressure sensor designed to provide highly accurate measurements in various environments. It has a measuring range of 30kPa to 120kPa and can operate in temperatures ranging from -20°C to 70°C. The sensor uses an SPI interface for communication with its host microcontroller and has internal calibration and compensation for both pressure and temperature output data.

Architecture of Murata SCP1000-D01

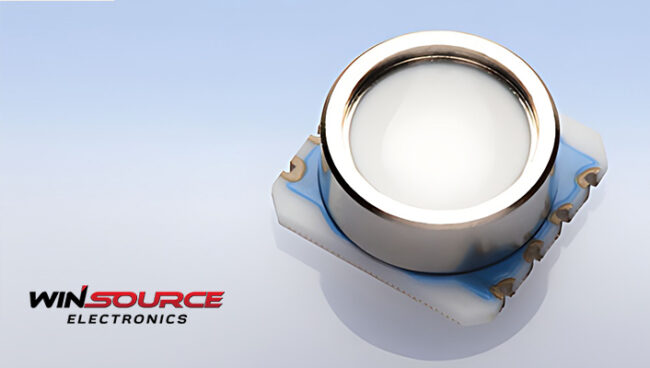

The SCP1000-D01 is built using VTI’s 3D-MEMS capacitive sensing element, which allows for accurate pressure measurements with a resolution of up to 17 bits. The sensor is also equipped with a low-power CMOS interface ASIC that has on-chip calibration memory and four preset measuring modes. These modes offer a range of options for power consumption and data read speed, allowing for flexibility in different applications.

The SCP1000-D01 is housed in a LCP (Liquid Crystal Plastic) MID (Molded Interconnect Device) package, making it suitable for surface mount applications. The circular vertical wall design of the housing also makes it easy to achieve waterproof sealing, adding to the sensor’s durability.

Measuring Modes

One of the key features of the SCP1000-D01 is its four user-selectable measuring modes, each with its unique combination of resolution and power consumption. The Low Power mode offers a resolution of 2 Pa (15 cm of air column) with a power consumption of only 3.5µA. This makes it ideal for applications that require low power consumption and can tolerate slightly lower resolution.

The Ultra-Low Power mode provides a resolution of 2 Pa (15 cm of air column) with an even lower power consumption of less than 5µA. This mode is perfect for battery-powered devices that require extended operation without frequent battery changes.

The High-Speed mode offers a higher resolution of 15 bits (18 cm of air column) at a data read speed of 9Hz, making it suitable for applications that require fast and precise readings. Finally, the Ultra-Low Power High-Speed mode combines the best of both worlds, offering a resolution of 15 bits and a power consumption of less than 5µA.

Applications

The Murata SCP1000-D01 has found its way into various applications that require accurate pressure measurements. One of the primary uses of this sensor is in barometric pressure measurement for weather forecasting and altitude tracking. The high accuracy and resolution of the SCP1000-D01 make it an ideal choice for these applications, providing reliable data for analysis.

Another application where the SCP1000-D01 excels is in altimeters for aviation and aerospace. With its ability to measure pressure levels with precision, the sensor can provide accurate altitude readings, which is essential for flight control and navigation.

The SCP1000-D01 is also used in industrial applications such as air compressors and pneumatic systems, where precise pressure control is crucial for efficient operation. It is also suitable for use in medical devices that require accurate measurement of blood pressure and respiratory function.

Advancements in Accuracy

As technology continues to advance, the demand for more accurate pressure sensors also increases. In response to this, Murata has developed an upgraded version of the SCP1000-D01 – the SCP1000-E01. This new sensor offers improved accuracy with a resolution of up to 20 bits and can measure pressure levels up to 150kPa.

The SCP1000-E01 also features a new on-chip digital signal processor that offers enhanced temperature compensation, resulting in even more precise measurements. These advancements make the SCP1000-E01 ideal for applications that require extremely accurate pressure readings.

Conclusion

Pressure sensors have evolved drastically in terms of accuracy and performance since their inception. The Murata SCP1000-D01 and its upgraded version, the SCP1000-E01, are a testament to this evolution.

As technology continues to advance, we can expect even more accurate and reliable pressure sensors in the future. If you are looking for high-quality pressure sensors like the SCP1000-D01 or other electronic components, visit WIN SOURCE – a trusted distributor of electronic components, providing a wide selection of products and excellent customer service.

COMMENTS