Design of a Power Transformer

At their core, power transformers operate on the principle of electromagnetic induction, a fundamental concept discovered by Michael Faraday in the 19th century. The basic design of a power transformer consists of a primary winding, a secondary winding, and a magnetic core. When an alternating current (AC) flows through the primary winding, it induces a magnetic field in the core. This magnetic field, in turn, induces a voltage in the secondary winding, enabling the efficient transfer of electrical energy.

Early power transformers were characterized by simple designs and low efficiency, limiting their application to specific voltage levels and power capacities. As electricity demand surged, engineers and researchers began to push the boundaries of transformer technology, leading to significant innovations.

The Rise of High-Voltage Transformers

One of the pivotal advancements in power transformer evolution was the development of high-voltage transformers. Engineers realized that by increasing the voltage, they could reduce energy losses during long-distance transmission. This breakthrough allowed for the creation of extensive power grids, connecting distant power plants to urban centers and industrial hubs.

The introduction of oil-filled transformers marked another milestone in the evolution of these devices. The oil served as both a coolant and an insulator, enhancing the transformer’s efficiency and reliability. This innovation paved the way for the widespread deployment of transformers in various applications, from industrial complexes to residential neighborhoods.

Efficiency Improvements: Core Materials and Cooling Systems

Continual efforts to enhance the efficiency of power transformers led to innovations in core materials and cooling systems. The traditional iron core was replaced by laminated cores made of high-grade steel, reducing energy losses and improving the overall performance of transformers. Additionally, advanced cooling methods, such as oil circulation and forced-air cooling, became standard features, ensuring that transformers could operate at optimal temperatures even under heavy loads.

Smart Transformers: A New Era Dawns

The 21st century witnessed the integration of smart technologies into power transformers, marking a paradigm shift in their functionality. Smart transformers, equipped with sensors and communication capabilities, could monitor their own performance in real-time. This ushered in an era of predictive maintenance, where potential issues could be identified and addressed before they led to costly failures.

Furthermore, smart transformers enabled grid operators to optimize the distribution of electricity, balancing loads more efficiently and enhancing the resilience of the power grid. Remote monitoring and control capabilities empowered utilities to respond swiftly to fluctuations in demand and emerging grid challenges.

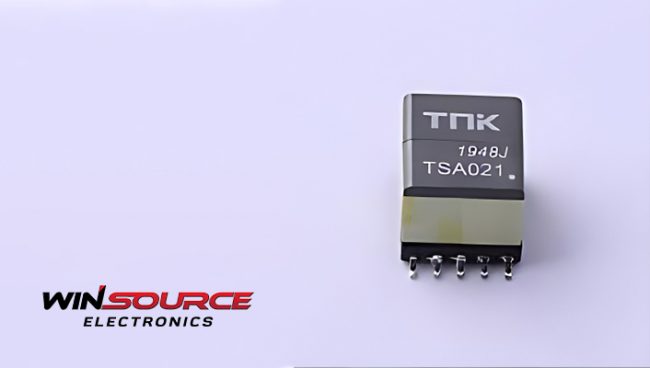

TNK TSA021: A Revolution in Transformer Technology

Among the latest innovations in power transformer technology, the TNK TSA021 stands out as a game-changer. Developed by leading manufacturers in collaboration with research institutions, the TNK TSA021 represents a convergence of cutting-edge materials, advanced design principles, and smart functionalities.

The TNK TSA021 introduces novel insulation materials that significantly enhance the transformer’s thermal and electrical performance. By pushing the boundaries of material science, researchers have created insulation systems that can withstand higher temperatures, allowing for increased power density without compromising safety and reliability.

Furthermore, the TNK TSA021 incorporates advanced sensors and diagnostic systems that provide unparalleled insights into the transformer’s health and performance. Real-time data analytics enable proactive maintenance strategies, reducing downtime and extending the operational life of the transformer.

The design of the TNK TSA021 also addresses environmental concerns. With a focus on sustainability, manufacturers have incorporated eco-friendly materials and manufacturing processes, aligning with the global push toward greener technologies.

TNK TSA021 Features: Redefining Transformer Performance

The TNK TSA021 represents a pinnacle in power transformer technology, incorporating a host of innovative features that redefine performance standards in the industry.

Here are the key attributes that set the TNK TSA021 apart from its predecessors:

Dual Primary Winding

The TNK TSA021 introduces a dual primary winding configuration, allowing for enhanced flexibility and adaptability in various voltage environments. With a primary side voltage range of 36V to 72V, this feature enables the transformer to seamlessly integrate into diverse electrical systems, catering to a wide spectrum of applications.

Single Secondary Winding

In a departure from traditional transformer designs, the TNK TSA021 features a single secondary winding. This streamlined approach contributes to the transformer’s efficiency by minimizing energy losses, ensuring that a higher percentage of the input power is effectively transferred to the secondary side.

Isolation Voltage of 1875V

Safety and reliability are paramount in power transformer design, and the TNK TSA021 excels in this aspect with an isolation voltage of 1875V. This ensures a robust insulation barrier between the primary and secondary windings, preventing electrical breakdown and enhancing the overall longevity of the transformer.

Wide Range of Secondary Side Voltage

The TNK TSA021 caters to diverse voltage requirements on the secondary side, with a configurable voltage range of 12V. This adaptability makes it well-suited for applications where precise voltage regulation is essential, providing a stable and reliable power supply to downstream electrical systems.

Advanced Monitoring and Diagnostic Systems

Embracing the era of smart transformers, the TNK TSA021 is equipped with advanced monitoring and diagnostic systems. These include sensors that continuously assess the transformer’s health and performance. Real-time data analytics empower operators with insights into the transformer’s condition, enabling predictive maintenance strategies and minimizing downtime.

Sustainable Design

In response to the growing emphasis on sustainability, the TNK TSA021 incorporates eco-friendly materials and manufacturing processes. The transformer is designed with a commitment to reducing its environmental impact, aligning with the global push for greener and more sustainable technologies.

High-Temperature Insulation Materials

The TNK TSA021 pushes the boundaries of material science by incorporating high-temperature insulation materials. This feature allows the transformer to operate at elevated temperatures, increasing power density without compromising safety or reliability. The use of advanced insulation materials contributes to the transformer’s overall efficiency and performance.

The introduction of TNK TSA021 represents a notable breakthrough in power transformer technology. This innovation likely brings about improvements in areas such as energy efficiency, environmental impact, and operational flexibility. The TNK TSA021 technology may play a pivotal role in shaping the future landscape of power distribution systems.

If you are in need of a reliable electronic component distributor then WIN SOURCE is one of the best platforms. You can browse through a number of power transformers and other components as well.

© 2025 Win Source Electronics. All rights reserved. This content is protected by copyright and may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of Win Source Electronics.

COMMENTS