* Question

What are the requirements for the construction of electronic tag antennas?

* Answer

The construction of electronic tag antennas, particularly for RFID systems, must meet specific requirements to ensure efficient, reliable, and accurate performance. Antennas play a crucial role in the functionality of RFID tags, as they are responsible for transmitting and receiving radio waves. Here are the key requirements and considerations for constructing electronic tag antennas:

1. Material Selection

– Conductivity: The antenna material needs to have good electrical conductivity to efficiently radiate and receive radio signals.

– Durability: Materials should be durable and able to withstand environmental conditions such as moisture, temperature extremes, and physical wear and tear.

– Cost-Effectiveness: Materials used must be economically feasible for large-scale production, balancing performance with cost.

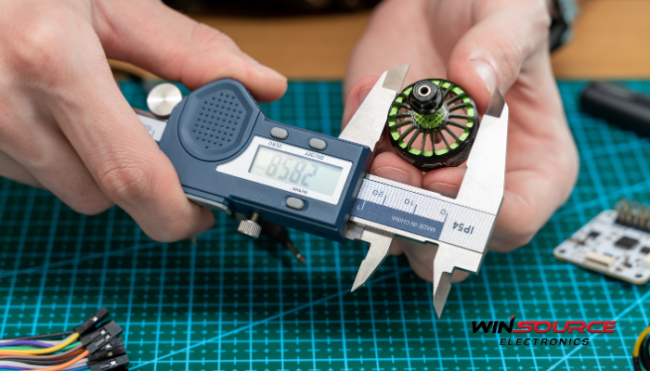

2. Design and Geometry

– Size and Shape: The size and shape of the antenna determine its resonance frequency and bandwidth. Antennas must be designed to resonate at the specific frequency used by the RFID system.

– Type of Antenna: Common types include dipole, loop, and patch antennas, each with different characteristics and suitability depending on the application.

– Impedance Matching: The antenna’s impedance must be matched with the RFID chip to maximize power transfer and thus, the range of the tag.

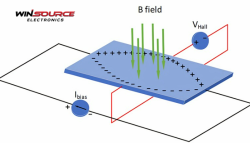

3. Frequency Compatibility

– Operating Frequency: Antennas must be designed to operate effectively at the specific frequencies dictated by the application, such as low frequency (LF), high frequency (HF), or ultra-high frequency (UHF).

– Environmental Factors: The antenna design may need to account for environmental factors that can affect radio wave propagation, such as materials that might cause interference or absorption.

4. Integration with the Tag

– Physical Integration: The antenna needs to be physically integrated with the RFID chip in a manner that supports its functionality and protects the components.

– Form Factor: The overall form of the RFID tag (e.g., label, hard tag, wristband) influences the design and placement of the antenna.

5. Read Range and Sensitivity

– Optimization for Range: Antenna design can significantly affect the read range, which is crucial for applications where tags need to be scanned from a distance.

– Sensitivity: The antenna must be sensitive enough to detect weak signals, ensuring reliable identification and tracking.

6. Environmental Resistance

– Weatherproofing: Antennas used outdoors or in harsh environments should be designed to resist water, dust, chemicals, and UV exposure.

– Temperature Tolerance: The antenna and its materials should tolerate the operating temperature range of the application environment.

7. Regulatory Compliance

– Standards and Regulations: Antenna designs must comply with local and international regulations concerning radio frequency emissions and safety standards.

8. Scalability and Manufacturability

– Ease of Manufacture: The antenna design should be easy to manufacture consistently at high volumes.

– Scalability: It should be feasible to scale the production of antennas as demand increases without significant changes to the design or materials.

These considerations ensure that the electronic tag antennas are optimized for performance, cost, and reliability, meeting the specific needs of various applications in tracking, identification, and data collection.

COMMENTS