* Question

What components are included in the measurement line of a micro-pressure transmitter?

* Answer

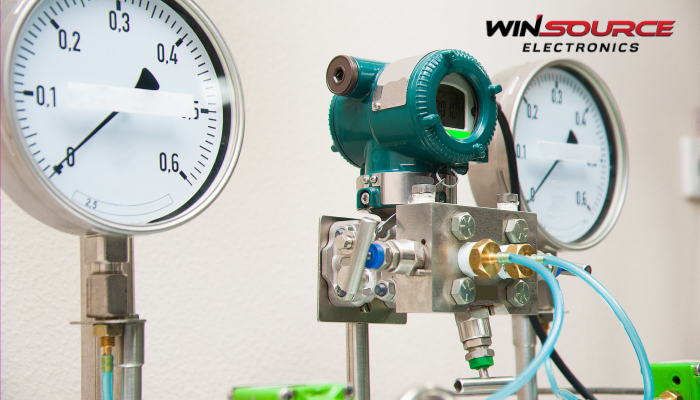

The measurement line of a micro-pressure transmitter typically consists of several key components that work together to ensure accurate detection of very low differential pressures. At the core of the system is the sensing diaphragm or pressure-sensitive element, which reacts to minute pressure variations and converts them into a measurable mechanical deflection. This deflection is then processed by an integrated piezoresistive, capacitive, or micro-electromechanical (MEMS) sensing structure, depending on the transmitter design.

To support stable signal conversion, the measurement line also includes a signal conditioning circuit, which amplifies, filters, and linearizes the raw sensor output. This ensures that weak micro-pressure signals remain accurate even in the presence of noise or temperature drift. Many transmitters incorporate temperature compensation components, such as embedded temperature sensors or calibration algorithms, to maintain measurement stability across varying environmental conditions.

Connection interfaces form another essential part of the measurement line. These include pressure ports, impulse lines, or capillaries that guide the measured medium to the sensing element without introducing distortion. Electrical interfaces—such as 4–20 mA loops, voltage outputs, or digital communication modules—provide a pathway for transmitting processed measurement data to control systems or monitoring equipment.

Together, these elements create a precise and stable measurement line capable of detecting extremely small pressure differences, making micro-pressure transmitters suitable for applications such as airflow monitoring, clean-room control, filter condition assessment, and low-pressure HVAC measurement.

COMMENTS