A diode is a semiconductor device that allows current to flow in one direction only. It acts as a one-way street for electrical current, permitting the flow from the anode (positive) to the cathode (negative) while blocking the reverse direction.

A rectifier diode is a specialized type of diode designed to convert alternating current (AC) into direct current (DC). This process is crucial for numerous electronic applications where a consistent DC voltage is required. Rectifier diodes facilitate the unidirectional flow of electric current, rectifying the input signal.

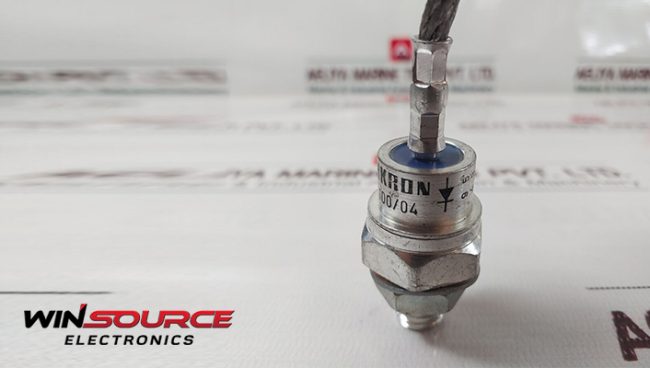

Now, let’s zoom in on the Semikron SKN 240/12 rectifier diodes. Specifically engineered for rectification purposes, these diodes play a pivotal role in converting AC to DC with precision. Let’s learn more about them.

Table of Contents

ToggleSemikron SKN 240/12 Overview

The Semikron SKN 240/12 is a rectifier diode designed to handle high-voltage and high-current applications. As a member of the SKN series, it is built with precision and efficiency in mind, making it suitable for a wide range of power electronic systems. The “240/12” designation indicates the diode’s voltage and current ratings, with a maximum voltage of 240 volts and a maximum current of 12 amperes.

Rectifier diodes, like the SKN 240/12, play a crucial role in converting alternating current (AC) to direct current (DC) in power supply circuits. Their performance directly impacts the efficiency and stability of power conversion processes, making a detailed analysis of their characteristics imperative.

Reverse Recovery Time in Diodes

The reverse recovery time of a diode is a critical parameter that defines how quickly the diode transitions from the conducting state to the blocking state when the polarity of the voltage across the diode changes. In other words, it is the time it takes for the diode to stop conducting after being forward-biased and then suddenly subjected to a reverse voltage.

Comprehending the reverse recovery time is crucial because during this transition, a diode exhibits a period of increased reverse current, known as reverse recovery current. This phenomenon can lead to power losses and voltage spikes, impacting the overall performance and reliability of the power electronic system.

Measurement and Significance of Reverse Recovery Time

Reverse recovery time is typically measured as the time between the instant the diode current becomes zero and the instant the reverse current reaches its peak negative value. This time is denoted as trr and is usually specified in nanoseconds (ns) or microseconds (μs).

For precision control applications, minimizing the reverse recovery time is essential. A shorter reverse recovery time results in reduced switching losses and minimizes the impact on the overall system efficiency. Additionally, it helps in achieving faster response times in applications where rapid transitions between conducting and non-conducting states are critical.

Analyzing Semikron SKN 240/12 Reverse Recovery Time

The reverse recovery time of the Semikron SKN 240/12 rectifier diode is a key aspect of its performance. Manufacturers provide detailed datasheets that include information on this parameter under various operating conditions. Engineers and designers must carefully analyze this information to ensure the diode’s compatibility with the specific requirements of their applications.

Semikron typically provides a graph depicting the reverse recovery characteristics of the SKN 240/12 diode over a range of temperatures and operating conditions. This graph allows engineers to visualize how the reverse recovery time varies with different parameters, aiding in the selection and optimization of the diode for a given application.

In precision control systems, where rapid switching and minimal power losses are critical, it is essential to choose a diode with a reverse recovery time that aligns with the system’s requirements. The datasheet of the SKN 240/12 diode provides insights into how the reverse recovery time changes with temperature, forward current, and other relevant factors.

Which Factors Affect Reverse Recovery Time?

Several factors influence the reverse recovery time of a diode, and understanding these factors is crucial for effective design and implementation. The main factors include:

Temperature: Reverse recovery time is often temperature-dependent. As the temperature increases, the mobility of charge carriers within the diode changes, affecting the speed of the recovery process. Engineers must consider the temperature range of their application to ensure the diode operates within specified parameters.

Forward Current: The reverse recovery time can also be influenced by the forward current passing through the diode. Higher forward currents may lead to longer reverse recovery times. Designers must consider the anticipated operating conditions and select a diode that meets the performance requirements at the expected current levels.

Diode Junction Capacitance: The junction capacitance of a diode, which is the result of the charge storage in the diode’s depletion region, can impact the reverse recovery time. A higher junction capacitance can extend the reverse recovery time, and designers must strike a balance between capacitance and recovery time based on the specific application.

What are the Practical Implications for Precision Control?

In precision control applications, the implications of reverse recovery time go beyond theoretical analysis. Engineers must consider the real-world effects of diode characteristics on the overall system performance. The following aspects are particularly relevant:

Switching Frequency and Efficiency: Precision control systems often operate at high switching frequencies to achieve the desired level of control. The reverse recovery time directly impacts the switching losses, and minimizing these losses is crucial for maintaining high efficiency in the system.

Voltage Spikes and EMI: The reverse recovery current during the diode transition can lead to voltage spikes and electromagnetic interference (EMI). In precision control applications, where signal integrity is paramount, managing voltage spikes and EMI becomes crucial for reliable system operation.

Dynamic Response: Rapid changes in the control signal necessitate fast transitions in the diode’s conduction state. A diode with a shorter reverse recovery time contributes to a faster dynamic response, ensuring that the system can quickly adapt to changing conditions.

How to Mitigate Reverse Recovery Effects?

To address the challenges posed by reverse recovery time in precision control applications, engineers can employ various mitigation strategies:

Snubber Circuits:

Snubber circuits, consisting of resistors and capacitors, can be added to the diode circuit to dampen the effects of reverse recovery. These circuits help reduce voltage spikes and minimize the impact of rapid diode transitions.

Soft Recovery Diodes:

Diodes specifically designed for fast and smooth transitions, known as soft recovery diodes, can be used in applications where minimizing reverse recovery effects is critical. These diodes are engineered to have controlled reverse recovery characteristics, offering improved performance in precision control systems.

Optimized Driving Signals:

The driving signals applied to the diode can be optimized to reduce the impact of reverse recovery. By carefully designing the control signals, engineers can minimize the time the diode spends in the reverse recovery state, thereby mitigating associated issues.

Conclusion

Through a thorough examination of the diode’s reverse recovery time, we have gained a deeper understanding of how quickly the diode can transition from the conducting to the non-conducting state after being subjected to a reverse-bias voltage. This information is crucial for designing and optimizing circuits where precise control and efficient switching are important.

The findings of this analysis contribute to the broader field of semiconductor device characterization, aiding engineers and researchers in making informed decisions about the suitability of Semikron SKN 240/12 diodes for specific applications.

If you want to purchase high-quality diodes or rectifiers, don’t hesitate to check out WIN SOURCE.

COMMENTS