In the field of modern electronic technology, pin connectors play a vital role. As an integral part of electronic equipment, pin connectors are used to connect electronic components, boards and external devices for signal transmission and power supply. However, many people only know the surface when it comes to the many types of pin connectors and their applications. This article will explore the different types of pin connectors in depth, including socket connectors, solder connectors, spring connectors and snap connectors, etc., and introduce their wide range of applications in various fields.

Table of Contents

ToggleSocket connector

The socket connector is the most common type of pin connector. It consists of two parts, a plug and a socket, and is connected by inserting the pins of the plug into the holes in the socket. The socket connector has the characteristics of easy installation, easy disassembly and high reliability. According to different connection methods and structures, socket connectors can be divided into the following types:

In-line connector

The plug pins of the in-line connector are directly inserted into the holes of the socket, and the common ones are single-row in-line, double-row in-line and patch connectors. They are widely used in board connection, power connection and signal transmission of electronic equipment.

Angle plug connector

The plug pins of the angled plug-in connector are bent and can be rotated and bent into the socket so that the connector can be connected vertically or on a plane. This connector is suitable for space-constrained applications such as televisions, computer monitors, and automotive dashboards.

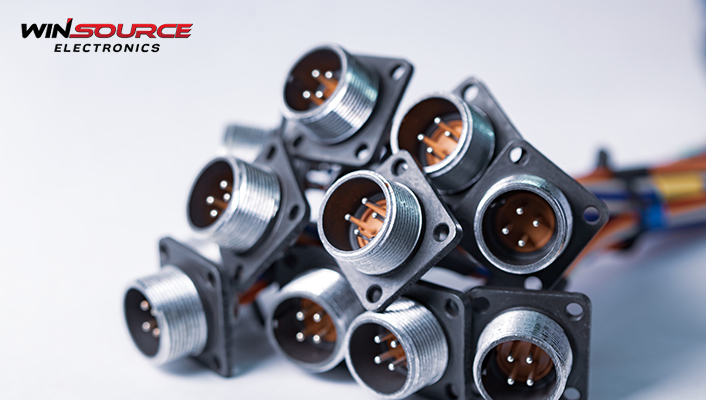

Pin connector

Pin connectors are a special type of socket connector in which the plug pins are needle-shaped. They are commonly used in applications requiring high-density connections and signal transmission, such as computer interconnects, test equipment, and medical equipment.

Socket connectors are widely used in electronic products, communication equipment, industrial automation, and automotive electronics, such as mobile phones, televisions, computers, aerospace equipment, and automotive electronic control systems.

Welding connector

Soldering connector is a connection method that fixes the connector on the electronic device by welding technology. It mainly includes two types of surface mount connectors (SMT) and plug-in connectors (Through-Hole).

Surface Mount Connectors (SMT)

A surface mount connector is a connector that is directly fixed to the surface of a printed circuit board (PCB) by soldering technology. It uses surface mount technology to solder the pins on the pads of the PCB for electrical connection. Surface mount connectors have the advantages of small size, light weight, and adaptability to high-density layouts. They are widely used in consumer electronics, communication equipment, medical equipment, and automotive electronics.

Plug-in connector (Through-Hole)

The plug-in connector is a connector that is inserted into a pre-drilled hole on the PCB by soldering technology and fixed on the PCB by soldering. The plug-in connector has the characteristics of stability, reliability and durability, and is suitable for applications that require high connection reliability and mechanical strength. Plug-in connectors are widely used in industrial automation, military aviation, medical instruments, and automotive electronics.

Spring connector

The spring connector uses elastic elements (such as spring sheets) as the connection medium, and connects the pins to the socket or the hole through elastic force. They feature quick connections, re-mating and vibration resistance. According to different structures and applications, spring connectors can be divided into two types: spring contact connectors and pogo pin connectors.

Spring Contact Connectors

Spring contact connectors use the elastic force between the spring blade and the pin of the plug to achieve the connection. They are widely used in communication equipment, computers, automotive electronics, and medical equipment, such as power sockets, signal connections, and modular equipment.

Pogo pin connector

The pogo pin connector uses pogo pins as the connection medium, and the pins are inserted into the socket or the hole slot by elastic force to realize the connection. Pogo pin connectors have good electrical contact performance and high reliability, and are often used in fields such as test equipment, aerospace equipment, and military equipment.

Snap connector

A snap connector is a connector that is connected and disconnected by a snap mechanism. They are suitable for application scenarios that require frequent plugging and unplugging, and are simple and fast. According to different snap mechanisms and application requirements, snap connectors can be divided into the following types:

Manual snap connector

Manual snap connectors are connected and disconnected by manual operation. They usually have a simple structure and operation mode, and are widely used in fields such as power connection, data transmission and instrumentation.

Self-locking snap connector

The self-locking snap connector has a self-locking mechanism, which can automatically lock the connection after the plug is inserted, and needs to press a specific button or release the locking mechanism to release the connection. Self-locking snap connectors are often used in applications that require connection reliability and anti-loosening, such as aerospace equipment and automotive electronics.

Magnetic Snap Connectors

Magnetic snap connectors use magnetic attraction to connect and disconnect. They are quick, easy, and can be connected without actually plugging and unplugging pins. Magnetic snap-fit connectors are commonly used in consumer electronics such as smartphones, tablets, and audio equipment.

Pin connectors have a wide range of applications, including but not limited to the following:

Electronic consumer goods

Pin connectors are widely used in consumer electronics such as mobile phones, televisions, audio equipment, and home appliances. They are used for functions such as power connection, data transmission, external device interface, and audio and video input and output, providing users with a convenient experience.

Automated industry

Pin connectors play a key role in industrial automation, connecting devices such as sensors, actuators, control modules and industrial robots. They can withstand harsh working environments and high-frequency plugging operations, ensuring reliable signal transmission and power supply.

Vehicle electronics

Automotive electronics is one of the important application fields of pin connectors. Pin connectors are used to connect automotive circuits, sensors, electric drive systems, and in-vehicle entertainment equipment, among others. They are anti-vibration, dust-proof, water-proof and high-temperature resistant, ensuring the stable operation of automotive electronic systems in harsh working environments.

Medical equipment

Medical equipment is an area that requires extremely high reliability and safety of connectors. Pin connectors are used in medical equipment to connect medical sensors, monitoring instruments, surgical equipment, and medical imaging equipment. They must be waterproof, corrosion-resistant and easy to clean to ensure the accuracy and stability of medical devices.

Summarize

As a vital part of electronic equipment, pin connectors realize signal transmission and power supply by connecting electronic components, boards and external devices. This article provides an in-depth exploration of the many types of pin connectors, including receptacle, solder, spring, and snap connectors, and describes their applications in consumer electronics, communications equipment, industrial automation, automotive electronics, Wide range of applications in fields such as medical equipment and aerospace.

For understanding the different types of pin connectors and their applications, it is helpful to choose a connector suitable for specific needs and ensure the reliability, stability and performance of electronic equipment. With the continuous development of technology, pin connectors are also constantly innovating and evolving, and are developing in the direction of high-speed transmission, high-density layout, reliability improvement and sustainable development. In the future, pin connectors will continue to play an important role in various fields, promote the progress of electronic technology, and bring more convenience and innovation to people’s life and work.

COMMENTS