* Question

What are the common fieldbuses?

* Answer

Fieldbuses are industrial communication systems that connect field devices, such as sensors, actuators, and controllers, in an automation or control system. They are designed for real-time, deterministic communication and are widely used in industries such as manufacturing, process control, and power systems. Here are some of the most common fieldbuses:

1. PROFIBUS

– Description: Widely used in factory and process automation. Developed by Siemens and the PROFIBUS user organization.

– Variants:

– PROFIBUS DP: High-speed communication for factory automation.

– PROFIBUS PA: Focused on process automation, including hazardous environments.

– Key Features:

– Supports cyclic and acyclic communication.

– Robust and reliable in industrial environments.

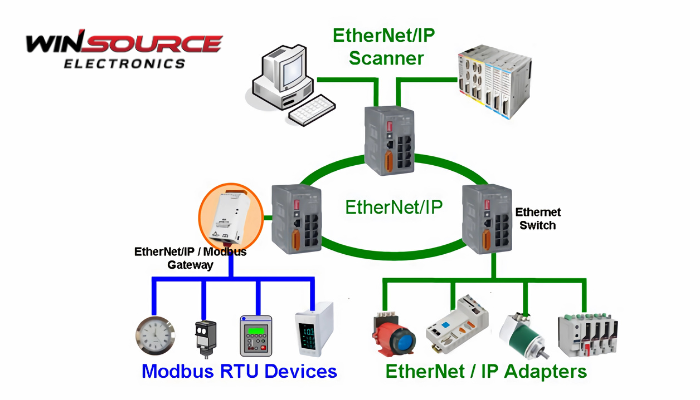

2. Modbus

– Description: A simple and open protocol used for industrial devices, developed by Modicon.

– Variants:

– Modbus RTU: Uses serial communication (RS-485 or RS-232).

– Modbus TCP: Operates over Ethernet networks.

– Key Features:

– Easy to implement and widely adopted.

– Master/slave architecture.

3. CANopen

– Description: A higher-layer protocol based on the Controller Area Network (CAN), often used in embedded systems and industrial automation.

– Key Features:

– Real-time data exchange.

– Supports distributed control systems.

– Flexible and highly configurable.

4. DeviceNet

– Description: Based on CAN technology and used for industrial automation and control systems.

– Key Features:

– Low-cost network solution.

– Supports plug-and-play device interoperability.

5. Foundation Fieldbus

– Description: Focuses on process automation and control, enabling distributed control at the field device level.

– Variants:

– H1: Operates at lower speeds (31.25 kbps) for process control.

– HSE (High-Speed Ethernet): Operates at Ethernet speeds.

– Key Features:

– True distributed control architecture.

– Interoperability between devices from different manufacturers.

6. EtherCAT

– Description: An Ethernet-based fieldbus designed for high-speed and real-time communication, primarily used in motion control.

– Key Features:

– Extremely low latency.

– High synchronization accuracy.

– Scalable network topology.

7. Profinet

– Description: An Ethernet-based protocol that extends the PROFIBUS functionality for industrial Ethernet applications.

– Key Features:

– High performance and flexibility.

– Integrated safety and motion control features.

8. Interbus

– Description: A fieldbus system developed by Phoenix Contact, focused on cyclic data exchange in industrial automation.

– Key Features:

– Simple and fast setup.

– Supports long cable distances.

9. AS-Interface (AS-i)

– Description: A simple, low-cost bus system for connecting actuators and sensors.

– Key Features:

– Simplified wiring with a flat two-wire cable.

– Used in safety applications.

10. BACnet

– Description: Commonly used in building automation for HVAC, lighting, and access control.

– Key Features:

– Open standard.

– Supports a variety of transport layers, including Ethernet, IP, and MS/TP.

11. HART (Highway Addressable Remote Transducer)

– Description: Combines analog and digital communication over a standard 4–20 mA current loop.

– Key Features:

– Compatible with existing analog systems.

– Bi-directional communication.

12. LonWorks

– Description: Primarily used in building automation and control applications.

– Key Features:

– Peer-to-peer communication.

– Supports distributed intelligence.

13. SERCOS

– Description: A high-speed fieldbus designed for motion control applications.

– Key Features:

– Real-time deterministic communication.

– High synchronization for motion devices.

Summary:

Each fieldbus protocol has its strengths and is suited for specific applications. The choice of fieldbus depends on factors like:

– Speed and latency requirements.

– Application domain (e.g., factory automation, process control, or building automation).

– Cost and complexity.

– Device compatibility.

COMMENTS